Vacuum arc remelting process melting speed control method based on online simulation model

A technology of vacuum arc remelting and melting speed, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of ingot current loss, achieve melting speed optimization, realize stable control, and ensure effective sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

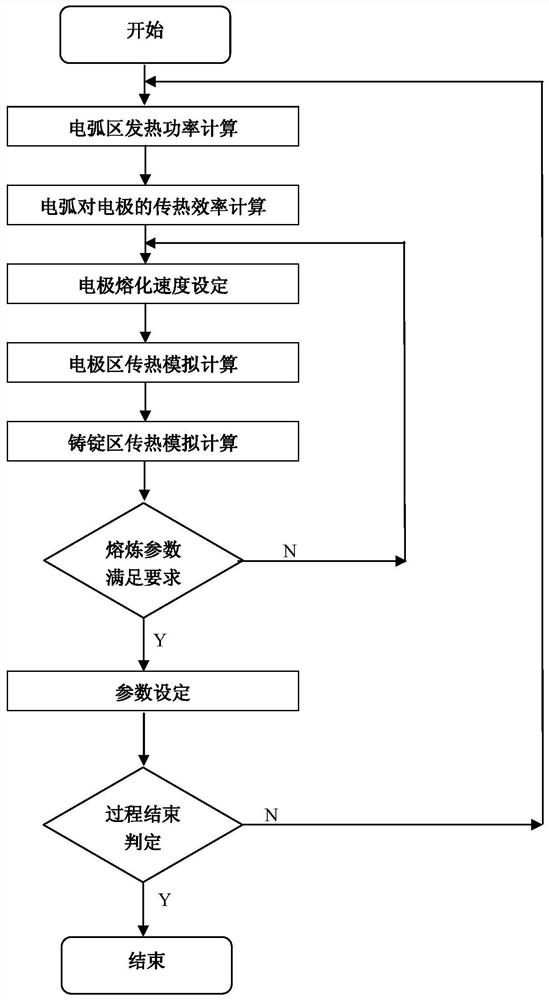

[0154] see figure 1 , the vacuum arc remelting process melting speed control method based on the online simulation model of the present invention, comprises the following steps:

[0155] 1) start

[0156] At the moment δt before the start of smelting, t=-δt;

[0157] Calculation control stage: n=0;

[0158] 2) Calculation of heating power in the arc area

[0159] Calculation control stage: n=n+1;

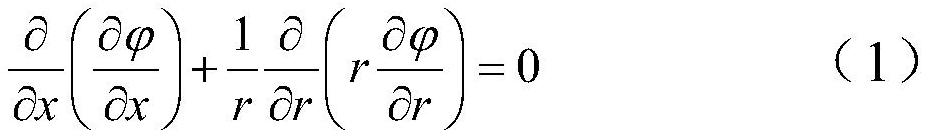

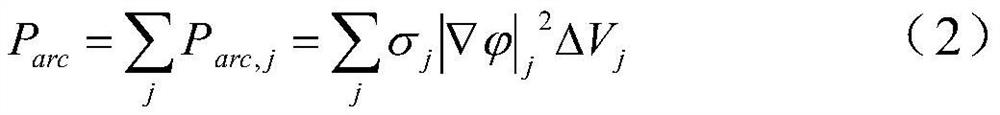

[0160] Using the detected voltage and current, using the potential equation, the arc area is equivalent to a uniform resistance, and the potential distribution calculation of the whole area (including: electrode, arc, ingot, casting mold, vacuum area, ingot / mold gap) is performed. , until the calculation converges. The potential equation is as follows:

[0161]

[0162] In the formula is the potential (V); x, r are the vertical and radial coordinates (m) respectively. Calculations are performed by discrete difference equations combined with boundary conditions. Using th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com