Preparation method of multi-layer composite soft magnetic ferrite core

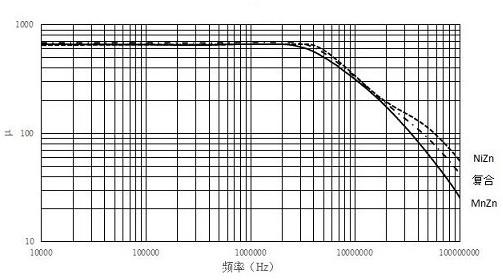

A soft magnetic ferrite, multi-layer composite technology, applied in the direction of magnetic core manufacturing, inductor/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve the problem of difficulty in reasonable control, large differences in sintering and other processes, and the inability to make flat or shape Complicated magnetic cores and other issues to achieve good electromagnetic characteristics and avoid performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

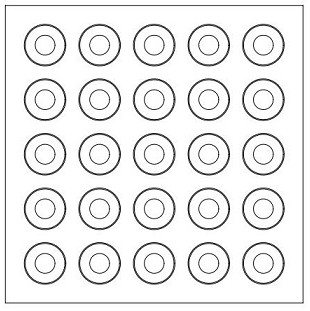

[0045] Prepare the NiMnZn composite soft ferrite core according to the following method, the structure schematic diagram of the composite blank is shown in figure 1 .

[0046] Disk manufacturing process:

[0047] Step (1): MnZn magnetic sheet is manufactured using commercially available Fe 2 o 3 (purity ≥ 99.3%), Mn 3 o 4 (Mn content ≥ 71%), ZnO (purity ≥ 99.7%) raw materials according to the main formula Fe 2 o 3 : 52.91mol%, ZnO is 18.84mol%, and MnO is the balance for batching;

[0048] Step (2): Put the prepared raw materials in a sand mill, add deionized water at a ratio of 1:1, add 5wt% dispersant, mix for 15 minutes, take out the slurry and place it in an oven at 130°C for drying Dry;

[0049] Step (3): The dried powder is pre-fired in a resistance furnace, the pre-fired atmosphere is air, the time is 2 hours, the temperature is 900 ° C, and then it is cooled to room temperature with the furnace;

[0050] Step (4): Add sub-recipe: 500ppm CaCO to pre-fired mater...

Embodiment 2

[0088] Prepare the MnZn composite soft ferrite core according to the following method:

[0089] Manufacturing process of MnZn ferrite type A magnetic sheet:

[0090] Step (1): Using commercially available Fe 2 o 3 (purity ≥ 99.3%), Mn 3 o 4 (Mn content ≥ 71%), ZnO (purity ≥ 99.7%) raw materials, according to the main formula Fe 2 o 3 : 53.28mol%, ZnO: 10.84mol%, Mn 3 o 4 Dosing for the remainder;

[0091] Step (2): Put the prepared raw materials in a sand mill, add deionized water at a ratio of 1:1, add 5wt% dispersant, mix for 15 minutes, take out the slurry and place it in an oven at 130°C for drying Dry;

[0092] The dried powder is pre-fired in a resistance furnace, the pre-fired atmosphere is air, the time is 2 hours, the temperature is 900 ° C, and then it is cooled to room temperature with the furnace;

[0093] Step (3): Add sub-recipe: 800ppm CaCO to pre-baked material 3 , 150ppmNb 2 o 5 , 200ppmZrO 2 , 4500ppmCo 2 o 3 , carry out secondary ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com