Turning strip stack composting process

A technology of turning over and composting, applied in the field of composting, can solve the problems of difficult to maintain the temperature of the compost, poor post-compost management effect, and poor killing effect of weed seeds, bacteria and larvae, so as to enhance the killing effect and ensure composting. The effect of quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

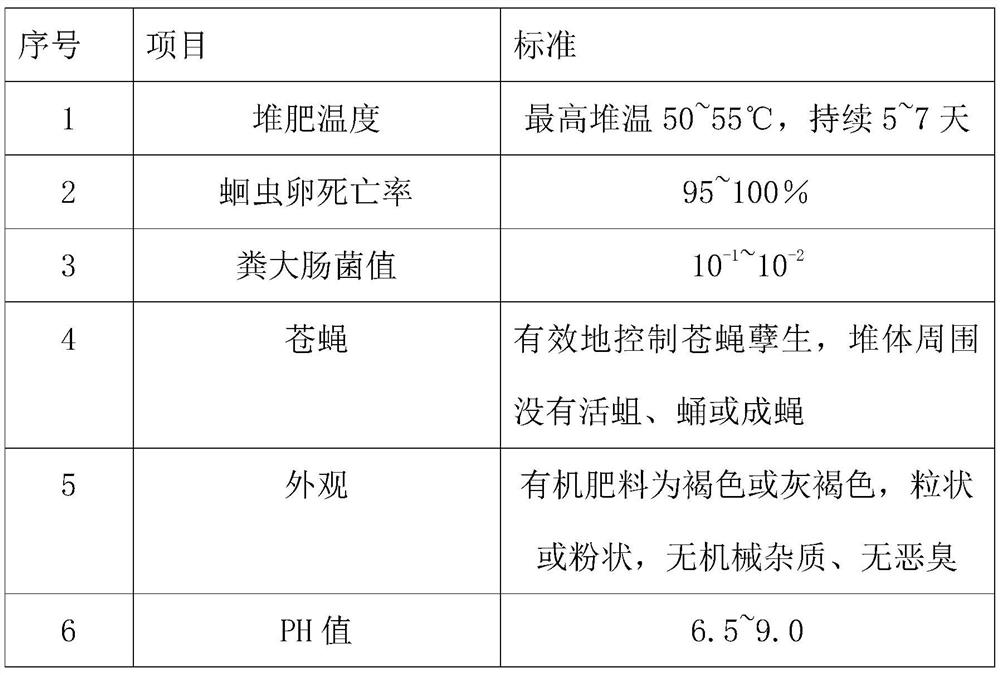

[0027] This embodiment provides a composting process of turning and throwing strips, which combines the unique turning and throwing technology with composting technology, so as to improve the problems of poor killing effect and poor post-composting management of traditional composting technology.

[0028] In the present embodiment, the specific technological process of turning over and throwing the bar pile composting process is as follows:

[0029] 1. Impurity removal and crushing: organic materials (litter, weeds, straw, bean cake, etc.) are removed and then crushed.

[0030] 2. Material mixing: the mixture of crushed organic material, organic decomposing agent and urea, in parts by weight, the ratio of organic material, organic decomposing agent and urea is 1000:1:5, for example: 1 ton of organic material Add 1 kg of decomposing agent (such as "301" bacterial agent, rotten spirit, chemical ripening agent, "HEM" bacterial agent, enzyme bacteria, etc.), and then apply 5 kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com