Lubricating grease composition for new energy automobile and preparation method of lubricating grease composition

A grease composition and material technology, applied in the field of grease, can solve the problems of extreme pressure and anti-wear properties, high-temperature anti-oxidation stability that cannot meet new energy vehicles, etc., and achieve good oxidation stability, good anti-wear performance, extreme good pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

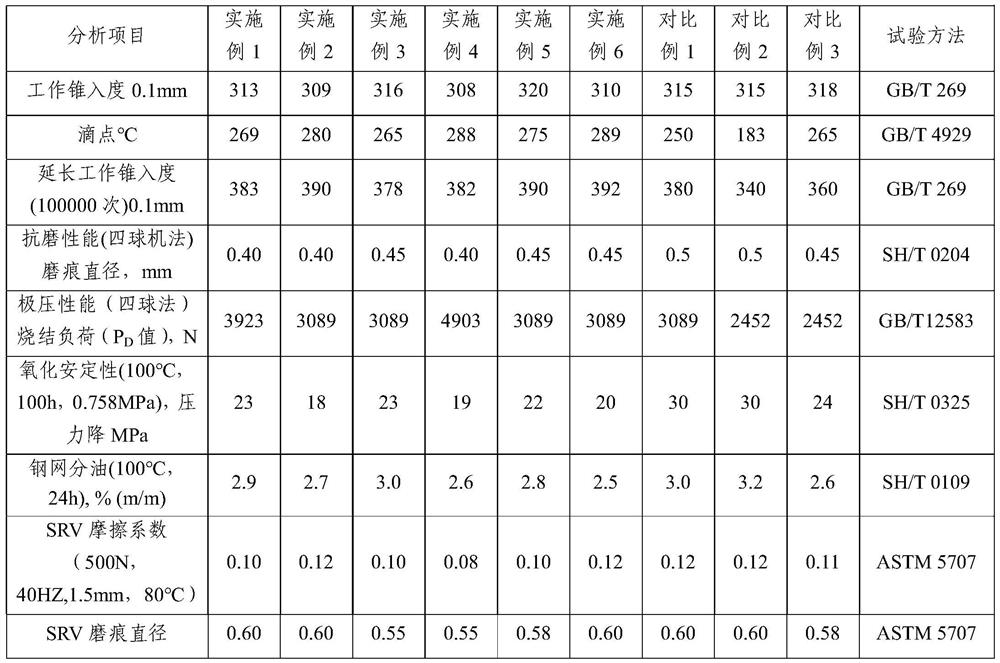

Examples

Embodiment 1

[0029] The present embodiment provides a kind of grease composition, and its preparation method comprises:

[0030] Add 600g of naphthenic mineral oil and 400g of synthetic oil into the reaction kettle, and put in 30g of acetic acid and 21g of calcium hydroxide for saponification reaction. The reaction time is 1h. When the temperature rises to 90°C, add 100g of 12-hydroxystearic acid to continue Saponification reaction, the time is controlled at 1h. After saponification is completed, the temperature is raised to 210°C, 150g of paraffin-based mineral oil is added, the temperature is controlled at 150°C after quenching, and 100g of paraffin-based mineral oil is added to cool down to 50°C. Finally, 15g of diphenylamine, 15g2 , 6-di-tert-butyl-p-cresol, 20g bis(2-ethylhexyl)molybdenum dithiophosphate, 10g molybdenum disulfide, after being uniformly dispersed by a three-roll machine, thicken and pack in cans.

Embodiment 2

[0032] The present embodiment provides a kind of grease composition, and its preparation method comprises:

[0033] Add 800g of naphthenic mineral oil and 200g of synthetic oil into the reactor, and put in 100g of 12-hydroxystearic acid and 30g of stearic acid and 21g of calcium hydroxide for saponification reaction, the time is controlled at 1h, and the reaction temperature is controlled at 90°C. Add 15g of terephthalic acid to continue the reaction. The reaction time is 1h. After the saponification is completed, the temperature is raised to 210°C, and 150g of paraffin-based mineral oil is added to control the temperature at 150°C after quenching. 15g of diisooctyldiphenylamine, 15g of 2,6-di-tert-butyl-p-cresol, and 30g of molybdenum bis(2-ethylhexyl)dithiophosphate were uniformly dispersed by a three-roller machine, then thickened and packed in cans.

Embodiment 3

[0035] The present embodiment provides a kind of grease composition, and its preparation method comprises:

[0036] Add 500g naphthenic mineral oil and 400g synthetic oil in reactor, and drop into 100g12-hydroxystearic acid and 21g calcium hydroxide and carry out saponification reaction, time is controlled at 1h, adds 25g benzoic acid to continue reaction, after saponification is completed, heat up to 210°C, add 200g of paraffin-based mineral oil, control the temperature after quenching at 150°C, then add 100g of paraffin-based mineral oil to cool down to 50°C, and finally add 15g of p-phenylenediamine, 15g of 2,6-di-tert-butyl p-cresol , 20g of bis(2-ethylhexyl)molybdenum dithiophosphate and 10g of graphite, uniformly dispersed by a three-roller machine, then thickened and packed in cans.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com