Polycrystalline diamond drawing die blank with hard alloy ring and preparation method thereof

A technology of hard alloy rings and polycrystalline diamonds, which is applied in metal processing equipment, metal extrusion forming tools, metal extrusion, etc. Thermal properties and impact toughness can be improved, and the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

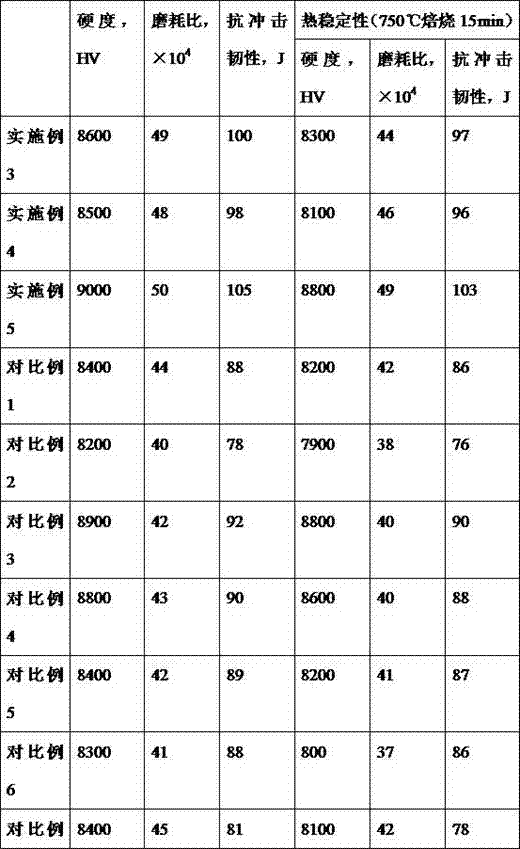

Examples

Embodiment 1

[0026] A kind of polycrystalline diamond drawing die blank with hard alloy ring that the present invention proposes comprises polycrystalline diamond core and hard alloy ring, and the raw material of polycrystalline diamond core comprises by weight: 100 parts of diamond micropowder, cubic boron nitride 10 parts, 2 parts of binder; the components of the cemented carbide ring include: Co: 2.5%, Cr: 1.2%, Mn: 1%, Y: 2%, Zr: 1%, Mo: 0.48%, Ti: 0.3%, N: 0.28%, C: 4%, and the balance is W.

[0027] The binder includes by weight: 4 parts of Ag powder, 8 parts of Al powder, 18 parts of Ni powder, 12 parts of Co powder, 6 parts of Zr powder, 20 parts of potassium fluoroaluminate, 20 parts of potassium fluoroborate, and 55 parts of phenolic resin.

[0028] The preparation method of the above-mentioned polycrystalline diamond wire drawing die blank with hard alloy ring that the present invention also proposes comprises the steps:

[0029] S1. Heat the raw material of the cemented carbid...

Embodiment 2

[0035]A kind of polycrystalline diamond drawing die blank with hard alloy ring that the present invention proposes comprises polycrystalline diamond core and hard alloy ring, and the raw material of polycrystalline diamond core comprises by weight: 100 parts of diamond micropowder, cubic boron nitride 20 parts, 1 part of binder; the components of the hard alloy ring include by weight percentage: Co: 3.5%, Cr: 0.6%, Mn: 1.2%, Y: 1%, Zr: 2%, Mo: 0.45%, Ti: 0.4%, N: 0.26%, C: 8%, and the balance is W.

[0036] The binder includes by weight: 2 parts of Ag powder, 12 parts of Al powder, 10 parts of Ni powder, 20 parts of Co powder, 4 parts of Zr powder, 30 parts of potassium fluoroaluminate, 15 parts of potassium fluoroborate, and 65 parts of polyurethane resin.

[0037] The preparation method of the above-mentioned polycrystalline diamond wire drawing die blank with hard alloy ring that the present invention also proposes comprises the steps:

[0038] S1. Heat the raw material of...

Embodiment 3

[0044] A kind of polycrystalline diamond drawing die blank with hard alloy ring that the present invention proposes comprises polycrystalline diamond core and hard alloy ring, and the raw material of polycrystalline diamond core comprises by weight: 100 parts of diamond micropowder, cubic boron nitride 12 parts, 1.8 parts of binder; the components of the cemented carbide ring include: Co: 2.8%, Cr: 1.1%, Mn: 1.05%, Y: 1.8%, Zr: 1.4%, Mo: 0.47%, Ti: 0.33%, N: 0.275%, C: 5%, and the balance is W.

[0045] The adhesive includes by weight: 3.5 parts of Ag powder, 9 parts of Al powder, 16 parts of Ni powder, 14 parts of Co powder, 5.5 parts of Zr powder, 22 parts of potassium fluoroaluminate, 18 parts of potassium fluoroborate, 20 parts of phenolic resin, 38 parts of polyurethane resin.

[0046] The preparation method of the above-mentioned polycrystalline diamond wire drawing die blank with hard alloy ring that the present invention also proposes comprises the steps:

[0047] S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com