A current distribution control method for a claw pole motor

A technology of current distribution and control method, applied in motor control, motor generator control, AC motor control and other directions, can solve the problems of data error sensitivity, slow search algorithm speed, etc., to achieve simple algorithm, simple and fast calculation, and less impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below with reference to the accompanying drawings.

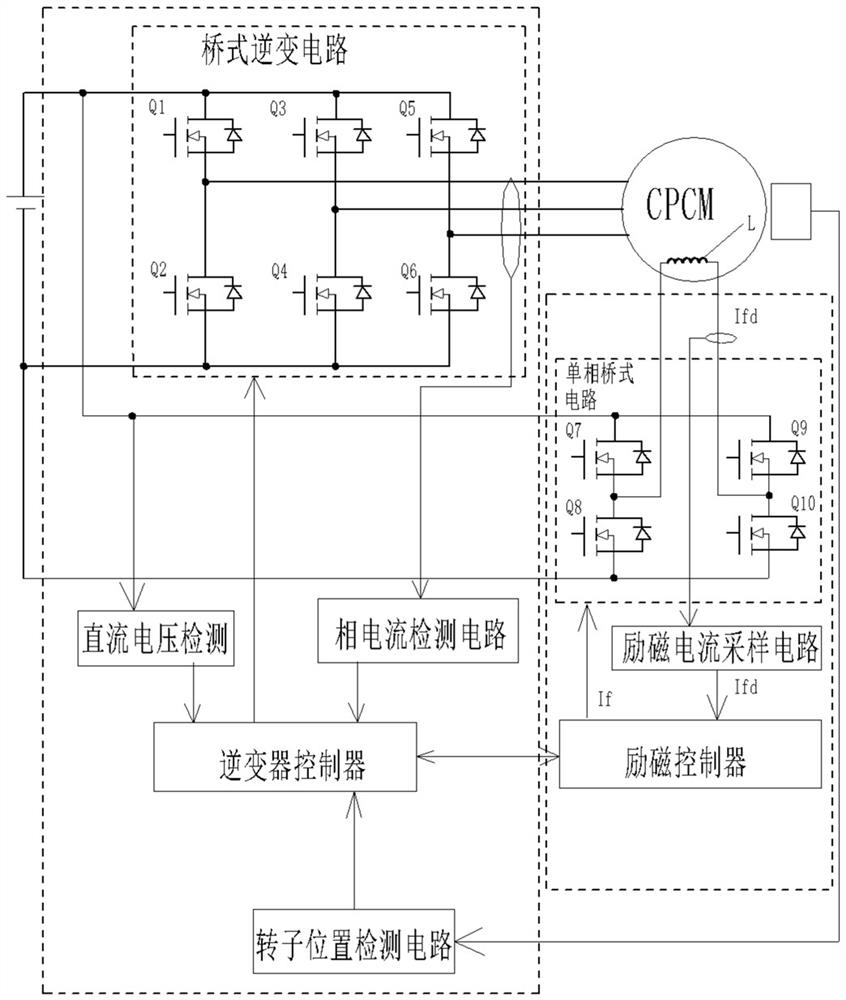

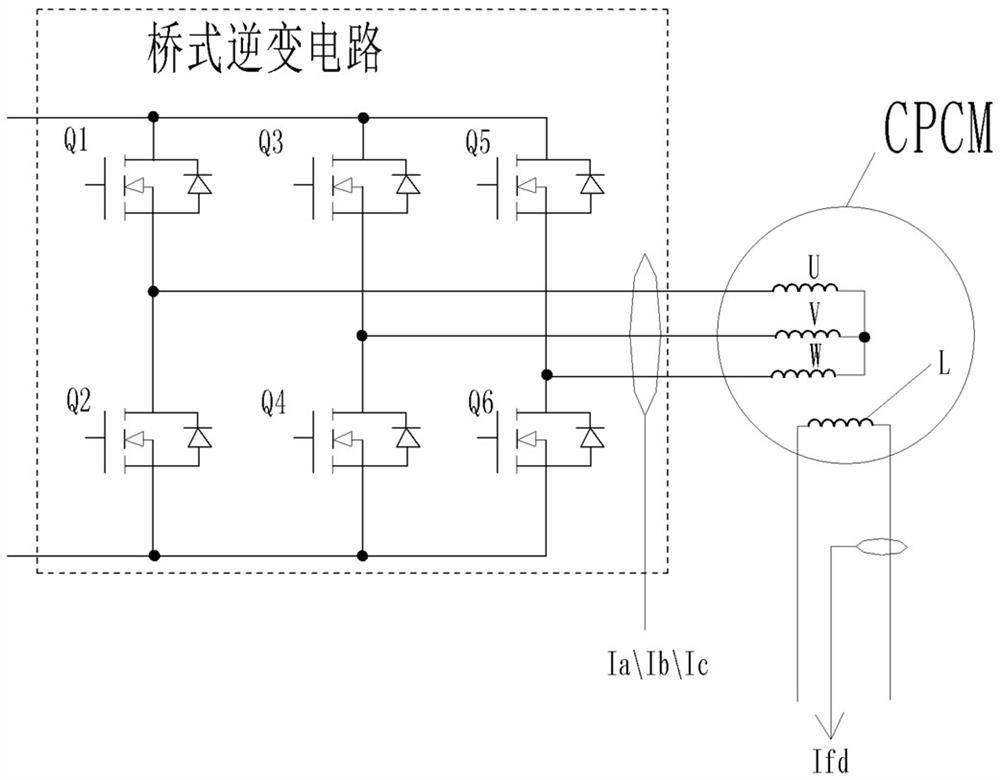

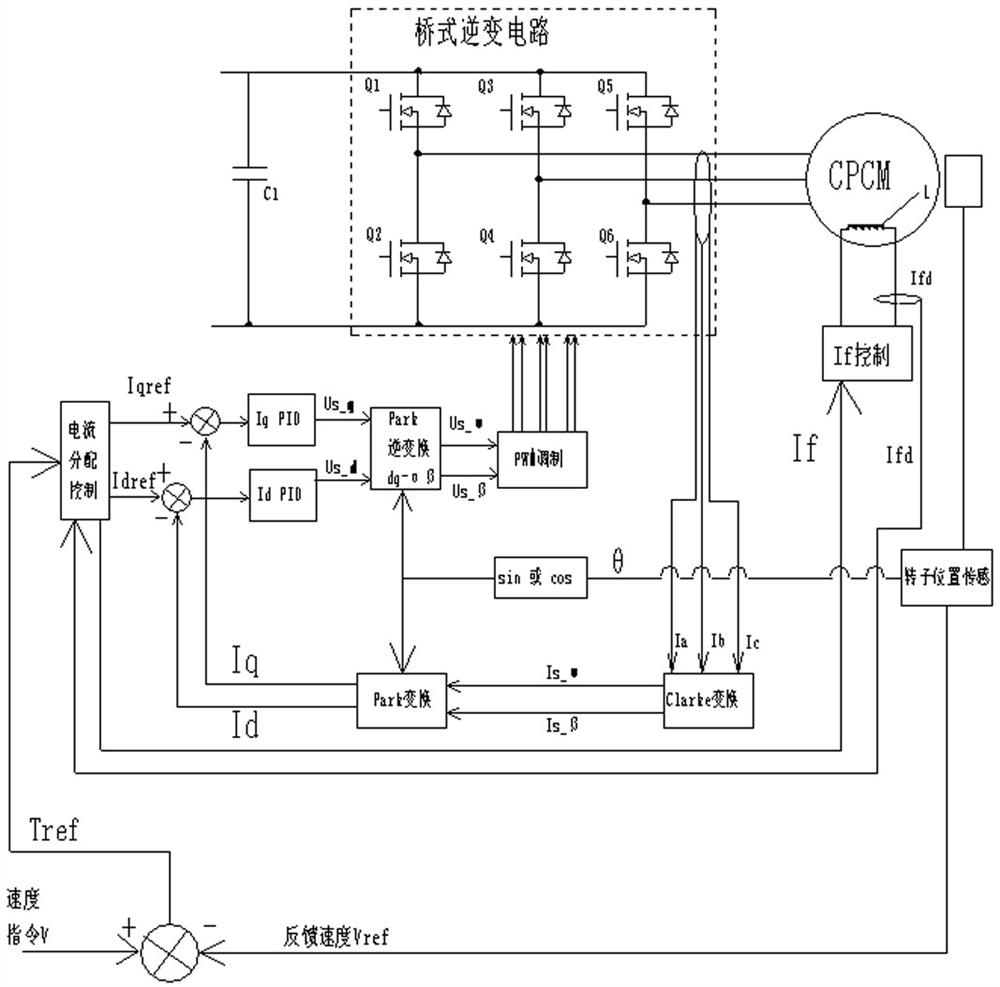

[0023] Such as figure 1 , figure 2 As shown, a claw electrical machine of the present invention comprises two portions of the motor body and the motor controller, the motor body including stator, rotor, and housing, and the stator comprises a stator core and wound on a stator core. Coil windings, rotors include exciting windings, rotor core, specific circuit structures such as figure 1 and figure 2 Design, the armature winding in the stator of the claw pole motor has a phase current of U, V, W three phase, rotor excitation windings L, armature windings U, V, W, IA, IB, IC, rotor excitation The excitation current IF of the winding L, the actual feedback excitation current IFD; the motor controller includes an inverter controller, a phase current detecting circuit, a DC voltage detection, a rotor position detecting circuit, a three-phase bridge inverter circuit, an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com