Synthesis of nano-silver colloid by polyol solvothermal method

A technology of nano-silver colloid and solvothermal method, which is applied in the direction of nanotechnology, nanotechnology, nano-medicine, etc., can solve the problems of not being able to achieve uniform particle size, shape and size uniformity of nano-silver materials, and achieve low cost, The effect of less impurities and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the 20ml system as an example:

[0030] (1) take silver nitrate 0.1413g and polyvinylpyrrolidone 0.9324g;

[0031] (2) Dissolve the weighed silver nitrate and polyvinylpyrrolidone in 10 ml of ethylene glycol solvent respectively, and then mix them ultrasonically for 10 min.

[0032] (3) The mixed solution was transferred to a reaction kettle, placed in an oven preset at 160° C., taken out after reacting for 4 hours, and cooled to room temperature to obtain a mother liquid of nano-silver colloid.

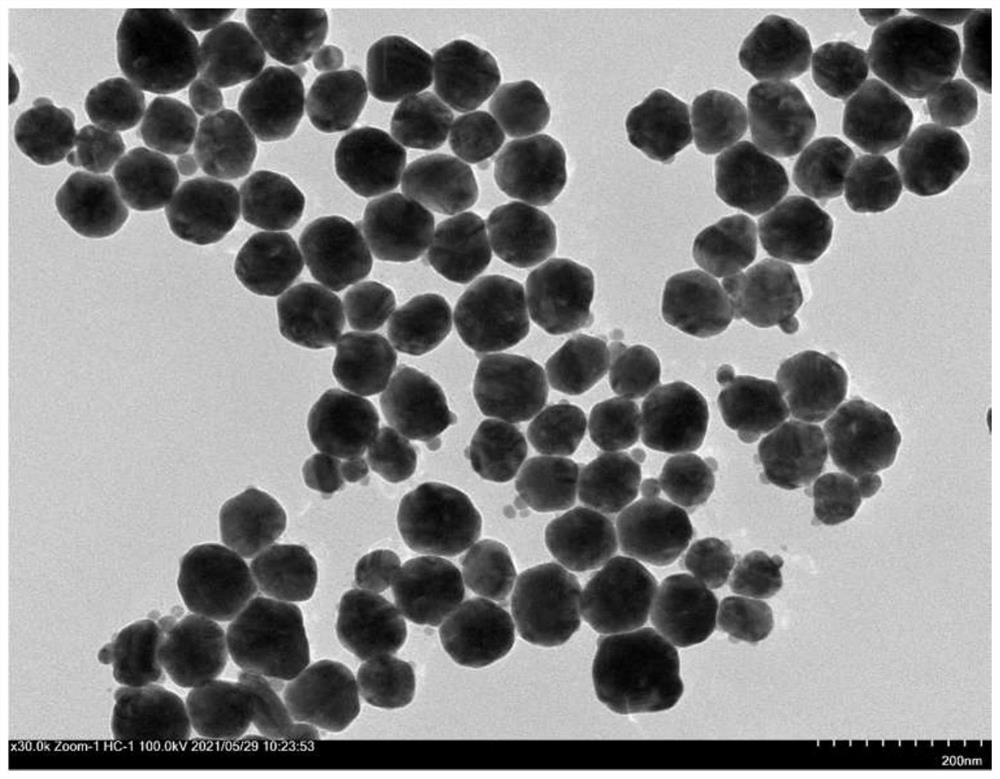

[0033] (4) Centrifuge the nano-silver colloid mother liquor in batches at 6000 rpm, remove the supernatant, and obtain a precipitate. After repeating the centrifugation process 4-5 times, the precipitate was dispersed in ultrapure water or absolute ethanol. figure 1 For the TEM photograph of the silver nano that obtains according to embodiment 1, from figure 1 It can be seen that the morphology of the prepared silver nanometer is complete, the average particle size is ...

Embodiment 2

[0035] Take the 20ml system as an example:

[0036] (1) Take silver nitrate 0.0588g and polyvinylpyrrolidone 0.4662g;

[0037] (2) Dissolve the weighed silver nitrate and polyvinylpyrrolidone in 10 ml of ethylene glycol solvent respectively, and then mix them ultrasonically for 10 min.

[0038] (3) The mixed solution was transferred to a reaction kettle, placed in an oven preset at 140° C., taken out after reacting for 6 hours, and cooled to room temperature to obtain a mother liquid of nano-silver colloid.

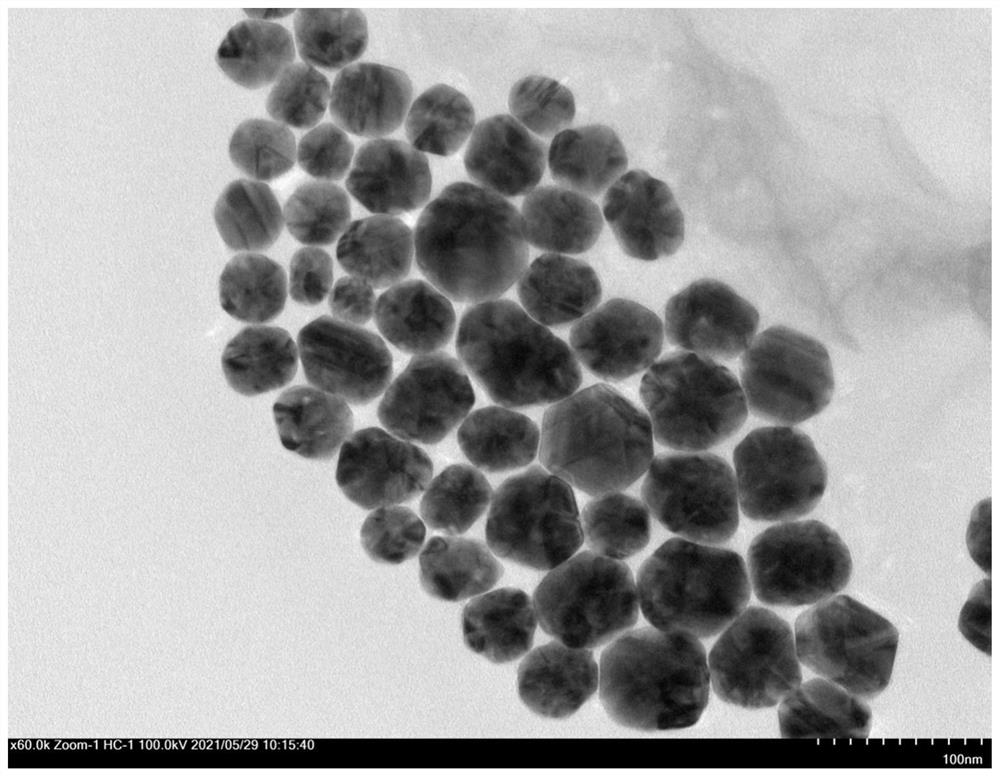

[0039] (4) Centrifuge the nano-silver colloid mother liquor in batches at 6000 rpm, remove the supernatant, and obtain a precipitate. After repeating the centrifugation process 4-5 times, the precipitate was dispersed in ultrapure water or absolute ethanol. figure 2 For the TEM photograph of the silver nano that obtains according to embodiment 2, from figure 2 It can be seen that the morphology of the prepared silver nanoparticles is complete, the average particle si...

Embodiment 3

[0041] Take the 20ml system as an example:

[0042] (1) Take silver nitrate 0.0850g and polyvinylpyrrolidone 0.9231g;

[0043] (2) Dissolve the weighed silver nitrate and polyvinylpyrrolidone in 10 ml of ethylene glycol solvent respectively, and then mix them ultrasonically for 10 min.

[0044] (3) The mixed solution was transferred to a reaction kettle, placed in an oven preset at 180° C., taken out after reacting for 8 hours, and cooled to room temperature to obtain a mother liquid of nano-silver colloid.

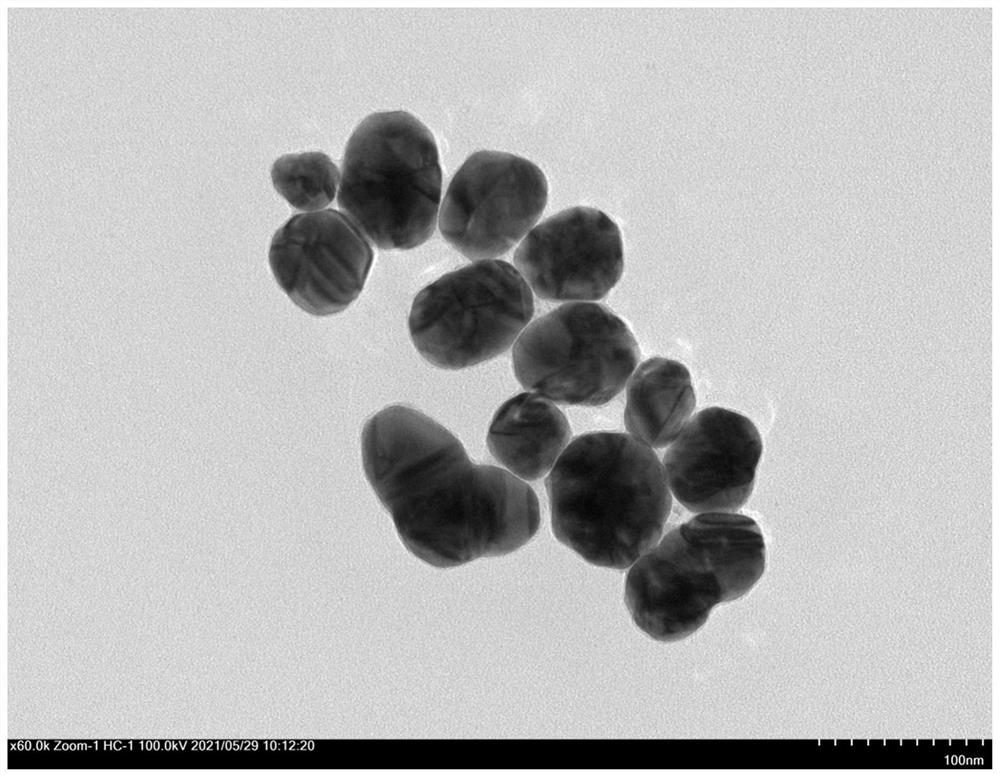

[0045] (4) Centrifuge the nano-silver colloid mother liquor in batches at 6000 rpm, remove the supernatant, and obtain a precipitate. After repeating the centrifugation process 4-5 times, the precipitate was dispersed in ultrapure water or absolute ethanol. image 3 For the TEM photograph of the silver nano that obtains according to embodiment 3, from image 3 It can be seen that the prepared silver nanoparticles have complete morphology and an average particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com