Automobile hub machining positioning system and intelligent cleaning and precision machining production line

A technology for automobile hubs and positioning systems, which is applied in the direction of wheels, metal processing, and positioning devices, which can solve the problems of positioning accuracy errors, high processing costs, and unreliability, and achieve improved processing accuracy, good self-locking performance, and reliable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

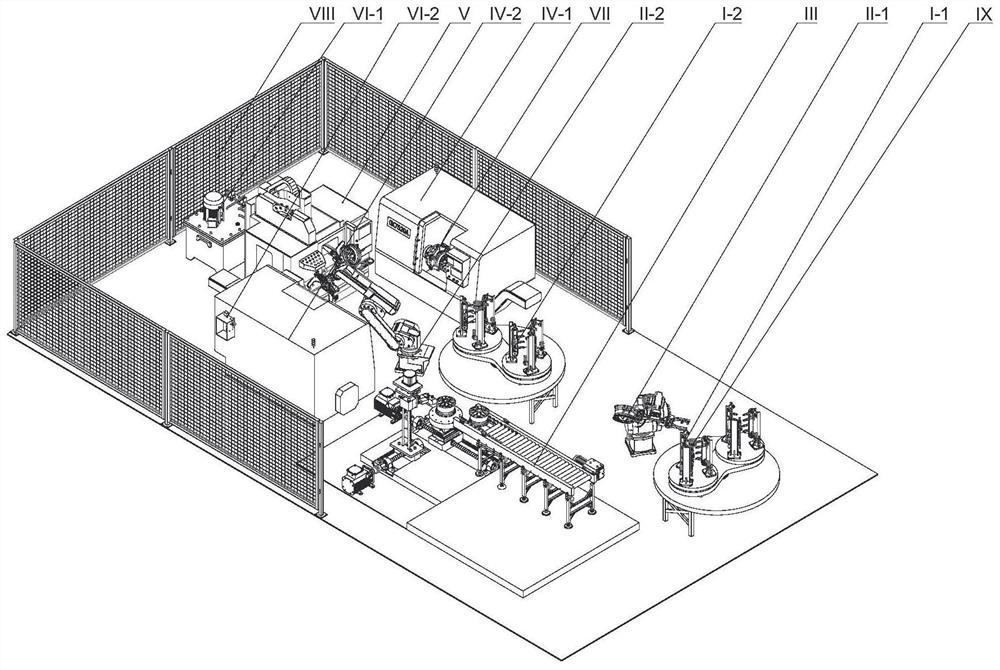

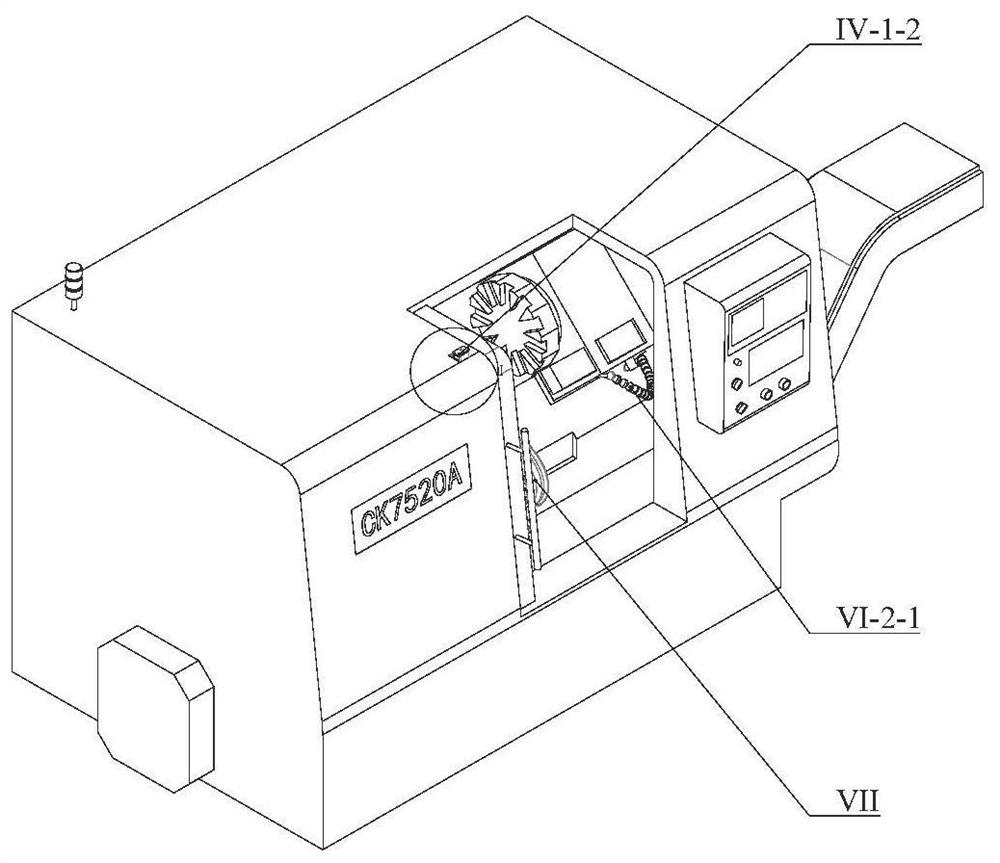

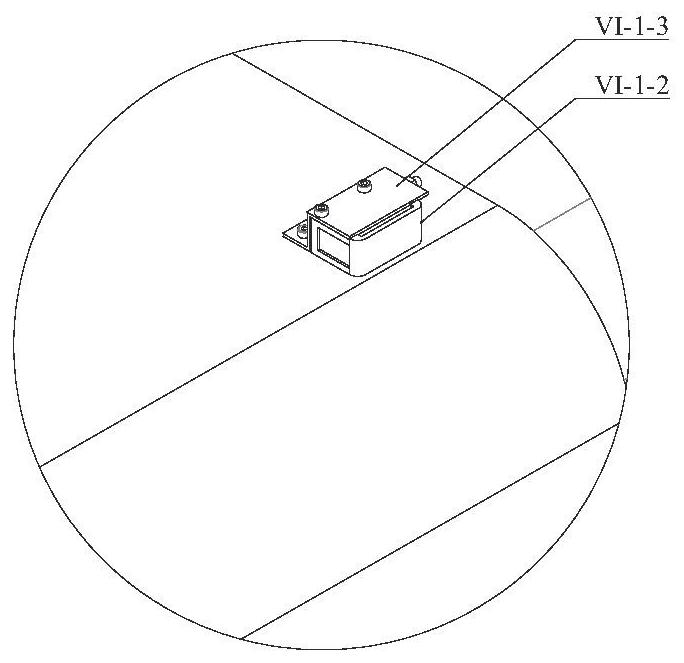

[0053] like figure 1 As shown, the car hub intelligent clean precision processing line proposed by the present embodiment is from the first shelf I-1, the second bracket I-2, the first robot II-1, the second robot II-2, the automatic hub three-dimensional Scanning device III, first horizontal lathe IV-1, second horizontal lathe IV-2, machining center V, trace lubricating fuel tank VI-1, trace lubricating apparatus VI-2, positioning system VII, protective fence VIII composition.

[0054] Among them, the protective fence VIII is disposed outside the first horizontal lathe IV-1, the second horizontal lathe IV-2, the outer side of the trace lubricating oil supply box Vi-1, and arranges the lower material frame along the second robot II-2. II-2, first horizontal lathe IV-1, second horizontal lathe IV-2, machining center V, automatic hub three-dimensional scanning device III, second robot II-2 and first horizontal lathe IV-1, The line IV-2 and the linear distance between the machining c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com