Method for preparing high-strength silicon mullite bricks

A high-strength technology of silicon mulberry brick, applied in the field of silicon mulberry brick manufacturing, can solve the problems of holes in the brick, reduce the strength performance of the silicon mulberry brick, affect the normal use of large-scale bricks, etc., and achieve the effect of easy access and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

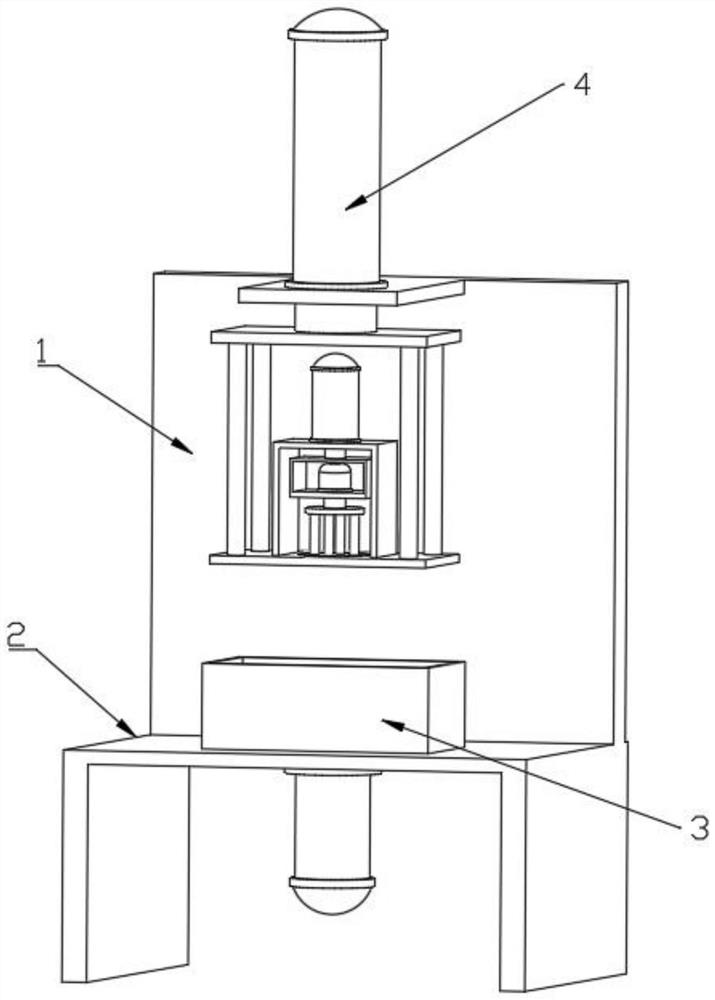

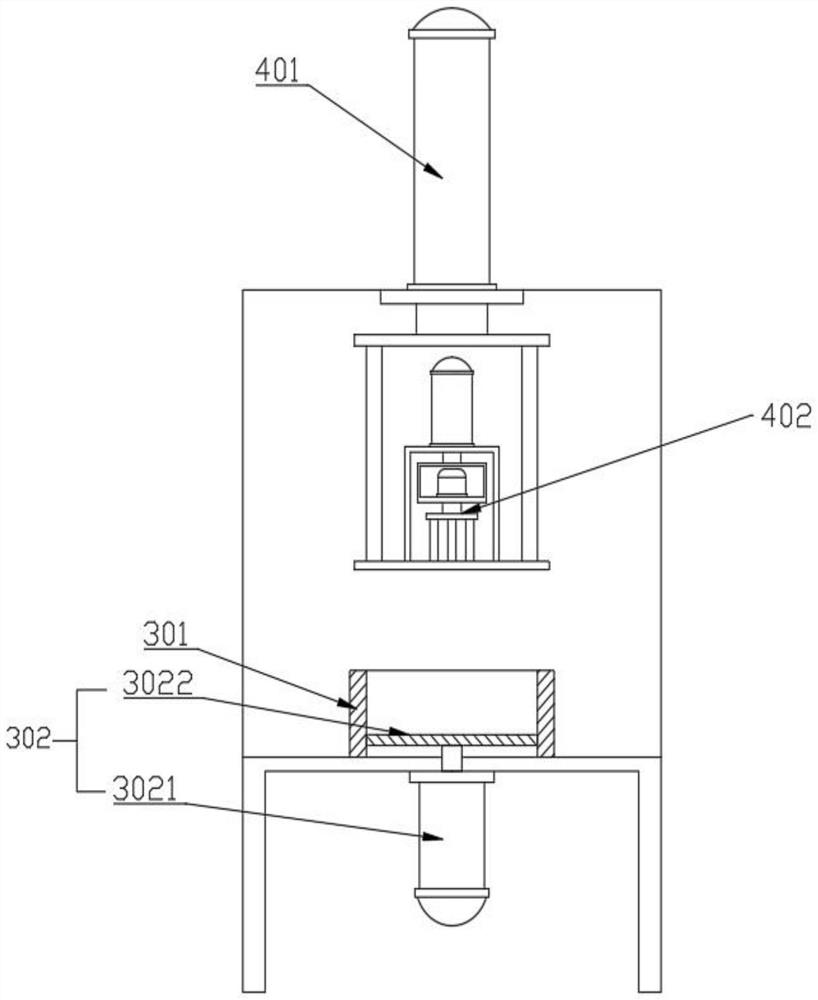

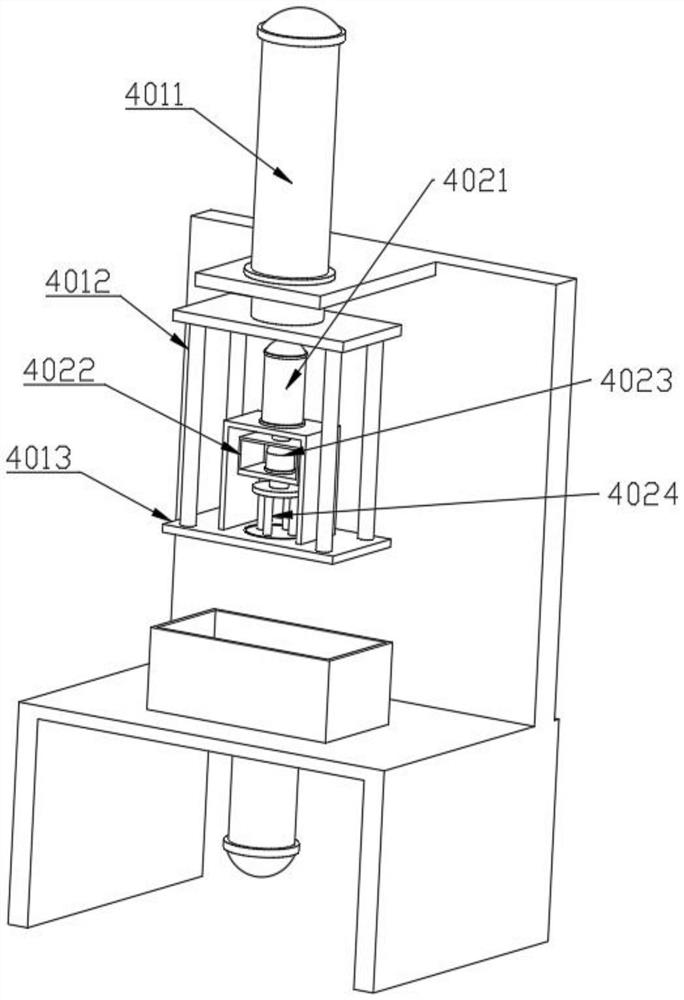

[0029] Specific embodiment one: please refer to Figure 1-4 A method for preparing high-strength silica bricks, S1: raw material mixing: inject the raw materials required for the production of silica bricks into the mixing tank, and stir and mix evenly; the raw materials required for the production of silica bricks include special grade bauxite 70~ 85%, silicon carbide 0.5-15%, industrial waste 0.5-15%, bonded clay 3-8% and water 2-5%; the mass percentage of Al2O3 in super-grade bauxite is ≧85%, and its particle size is ≦5mm; The mass percentage of SiC in silicon carbide is ≧95%, and its particle size is ≦5mm; the particle size of industrial waste residue is ≦0.088mm; the mass percentage of Al2O3 in bonded clay is ≧35%, and its particle size is ≦0.088mm; Put the super-grade bauxite and silicon carbide into the mixing tank for dry mixing, the dry mixing time is 3-5 minutes, then pour water into the mixing tank for 2-3 minutes; then pour in industrial waste Combined with clay, ...

specific Embodiment 2

[0036] Specific embodiment two, refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that the structure of the air-removing assembly 402 is different, and the specific difference is that: the air-removing assembly 402 also includes a baffle assembly 403, and the baffle assembly 403 includes a baffle cylinder 4031 and a movable baffle 4032; the baffle The cylinder 4031 is fixedly installed on the upper end surface of the pressing plate 4013, and the output end of the baffle cylinder 4031 is fixedly connected with the inner end surface of the movable baffle 4032. The movable baffle 4032 suppresses the raw materials in the molding die 301, so as to prevent the parts on the pressing plate 4013 from directly pressing the raw materials, resulting in an uneven surface of the brick embryo. The lower end surface of the pressing plate 4013 is provided with a slide rail 4017, and the upper end surface of the movable baffle 4032 is provided with a slide block 40...

specific Embodiment 3

[0037] Specific embodiment three, refer to Figure 7 , The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the structure of the molding die 301 is different, and the specific difference is that the outer wall of the molding die 301 is fixed with a vibration pump 5 . The vibrating pump 5 can drive the forming mold 301 to vibrate, thereby driving the raw materials in the forming mold 301 to vibrate, and further vibrating to remove air bubbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com