A kind of anti-agglomeration thickening type silicon dioxide and preparation method thereof

A technology for thickening silicon dioxide and silicon dioxide, which is applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc., can solve the problems of low water absorption, low specific surface area, and high dispersion of silicon dioxide, and achieve improved Dispersion performance, excellent performance, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

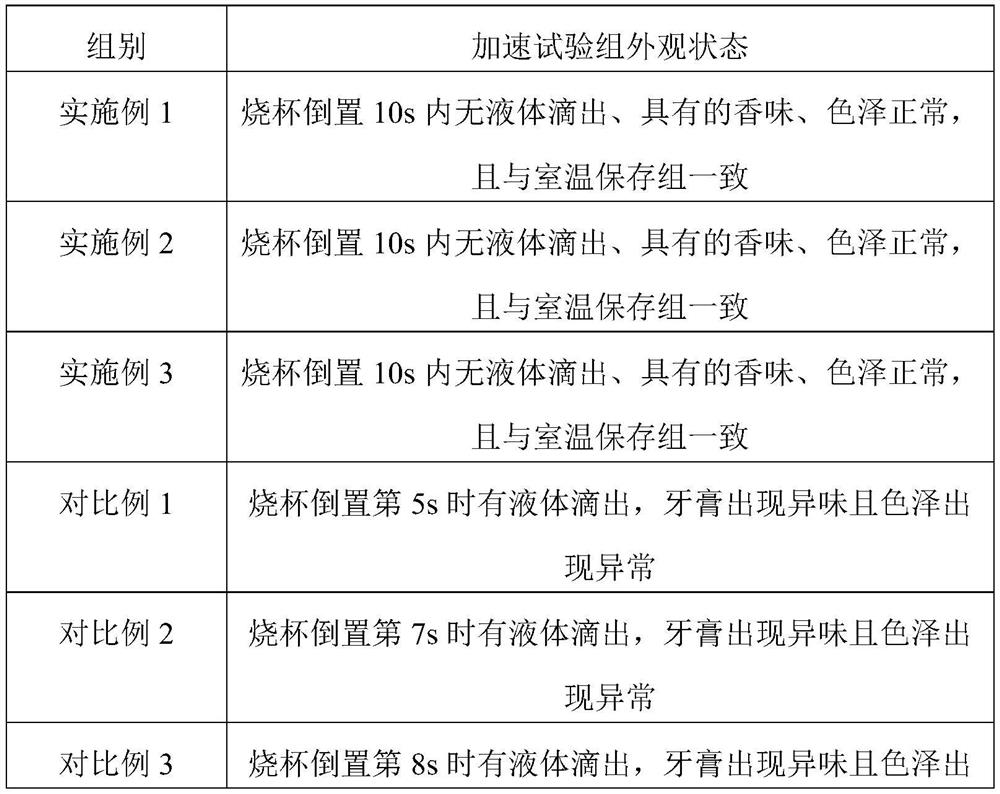

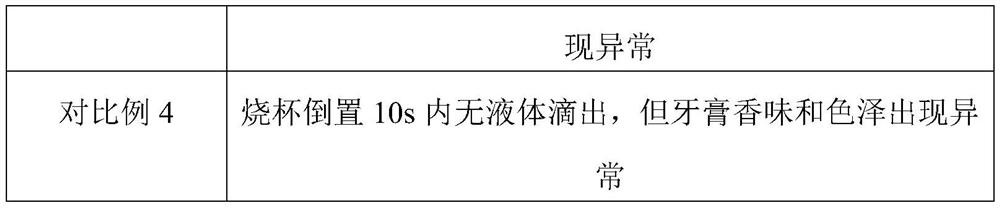

Examples

Embodiment 1

[0025] Embodiment 1, a kind of preparation method of anti-agglomeration thickening type silica

[0026] Preparation method: S1. Add water glass with a modulus of 3 to dilute, dissolve and age for 5 hours, take the aged water glass and dilute it with water to prepare a water glass solution with a concentration of 0.35M; inject water with a concentration of 0.35M into the reaction tank Glass Solution 14m 3 , heat up to 60°C, stir at a stirring speed of 30Hz, add 0.05% diboron trioxide by mass of water glass, stir and disperse evenly to form a water glass mixed solution;

[0027] S2: configure a sulfuric acid solution with a concentration of 3.5M to ensure that the acid solution is free of impurities;

[0028] S3: Add dropwise the sulfuric acid solution prepared in step S2 to the water glass mixed solution prepared in step S1 that is heated to 60°C, and the speed of incrementally adding the sulfuric acid solution is 2.0 m 3 / h, the pH of the reaction end point is 4.0, and the s...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of anti-agglomeration thickening type silica

[0031] Preparation method: S1. Add water glass with a modulus of 3.3 to dilute, dissolve and age for 6 hours, take the aged water glass and dilute it with water to prepare a water glass solution with a concentration of 0.45M; inject water with a concentration of 0.45M into the reaction tank Glass Solution 14m 3 , heating up to 80°C, stirring at a stirring speed of 25Hz, adding diboron trioxide with 0.1% water glass mass, stirring and dispersing evenly to form a water glass mixed solution;

[0032] S2: configure a sulfuric acid solution with a concentration of 3.6M to ensure that the acid solution is free of impurities;

[0033] S3: dropwise add the sulfuric acid solution prepared in step S2 to the water glass mixed solution prepared in step S1 that is heated to 70°C, and the speed of incrementally adding the sulfuric acid solution is 2.5 m 3 / h, the pH at the end of the reaction ...

Embodiment 3

[0035] Embodiment 3, a kind of preparation method of anti-agglomeration thickening type silica

[0036] Preparation method: S1. Add water glass with a modulus of 3.5 to dilute, dissolve and age for 8 hours, take the water glass after aging treatment and dilute it with water to prepare a water glass solution with a concentration of 0.50M; inject water with a concentration of 0.50M into the reaction tank Glass Solution 14m 3 , heat up to 70 ° C, stir, the stirring speed is 20 Hz, and add diboron trioxide with a mass of 0.2% water glass, stir and disperse evenly, and form a water glass mixed solution;

[0037] S2: configure a sulfuric acid solution with a concentration of 4.0M to ensure that the acid solution is free of impurities;

[0038] S3: dropwise add the sulfuric acid solution prepared in step S2 to the water glass mixed solution prepared in step S1 that is heated to 80°C, and the speed of incrementally adding the sulfuric acid solution is 3.0 m 3 / h, the pH at the end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com