Light flame-retardant insulation board for building external wall and preparation method thereof

A flame-retardant thermal insulation and building exterior wall technology, which is applied in the field of flame-retardant thermal insulation boards, can solve the problems that flame-retardant thermal insulation boards cannot achieve a good flame-retardant effect, cannot guarantee personal safety well, and the production line occupies a large area. Achieve the effects of easy promotion, good personal safety, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

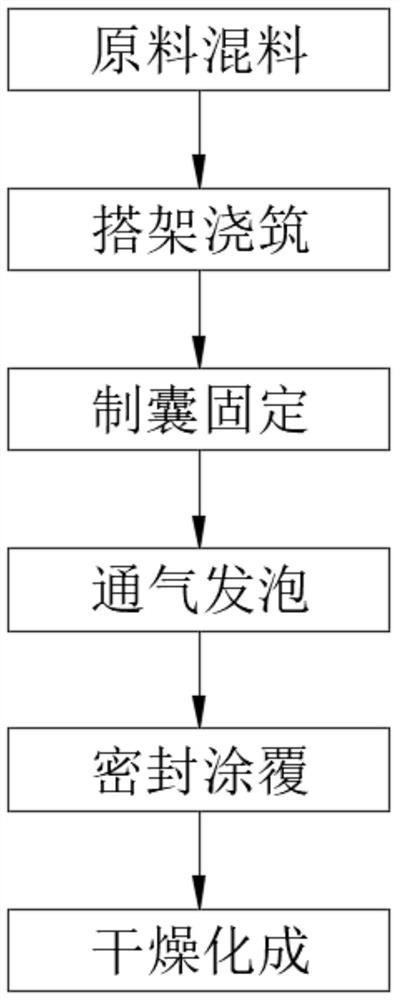

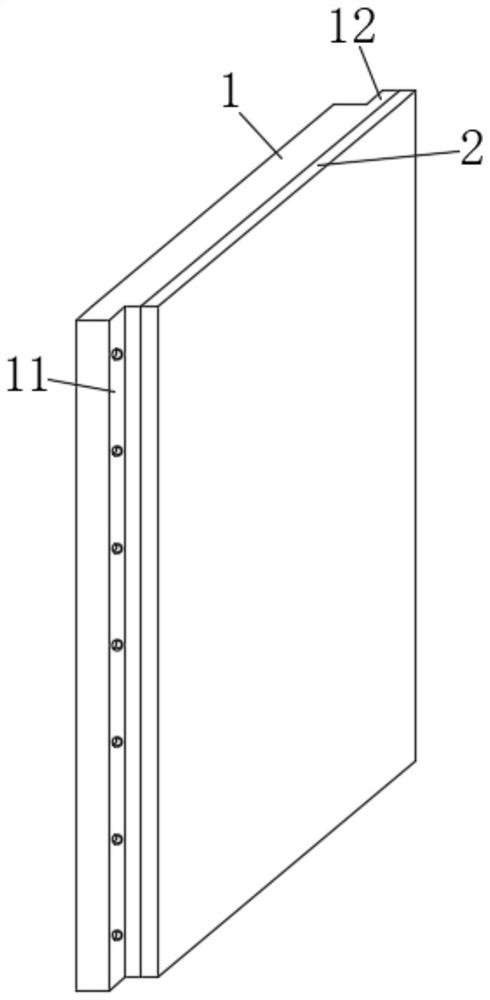

[0045] see figure 1 Shown, a kind of preparation method of light flame retardant insulation board for building exterior wall, comprises the following steps:

[0046] Step 1, raw material mixing: melting and blending high-density polyethylene with coupling agent, foaming agent, aramid fiber and phenolic resin to prepare base material A; melting and mixing high-density polyethylene and fire retardant to prepare base material B;

[0047] Step 2, frame casting: place the skeleton in the mold for fixing, then pour the base material A in the mold, and then use a vibrator to vibrate the base material A evenly;

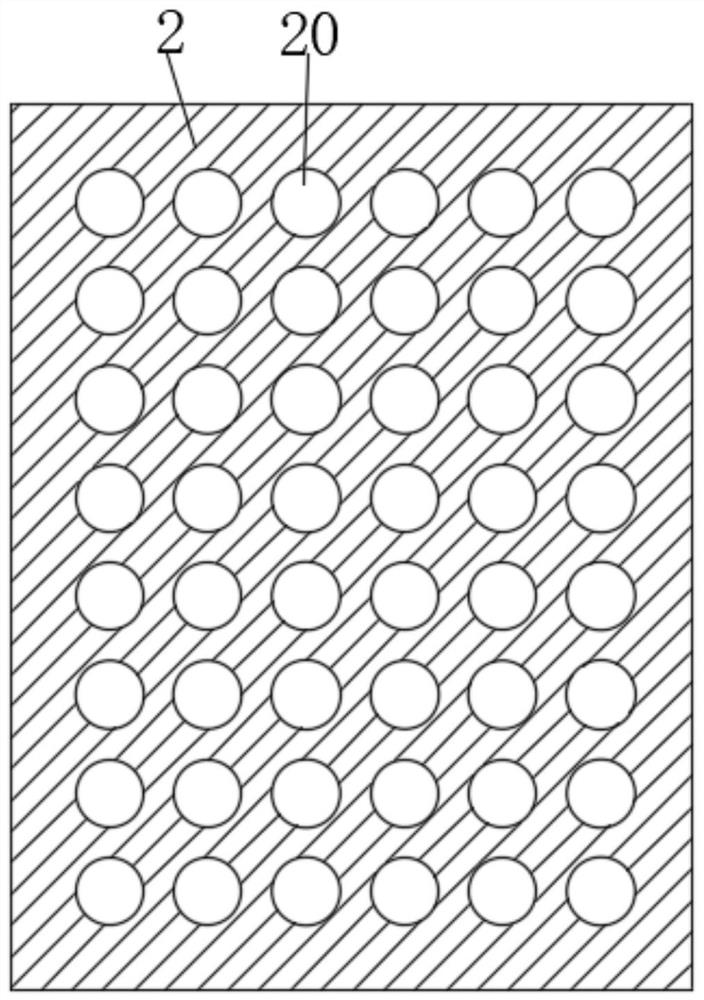

[0048] Step 3, making and fixing the capsule: preparing the flame-retardant capsule 20 and sequentially fixing the flame-retardant capsule 20 on the upper surface of the base material A in the mould;

[0049] Step 4. Ventilation and foaming: Inject carbon dioxide into the base material A in the mold, and let it stand for foaming:

[0050] Step 5, seal coating: after the foa...

Embodiment 2

[0072] see figure 1 Shown, a kind of preparation method of light flame retardant insulation board for building exterior wall, comprises the following steps:

[0073] Step 1, raw material mixing: melting and blending high-density polyethylene with coupling agent, foaming agent, aramid fiber and phenolic resin to prepare base material A; melting and mixing high-density polyethylene and fire retardant to prepare base material B;

[0074] Step 2, frame casting: place the skeleton in the mold for fixing, then pour the base material A in the mold, and then use a vibrator to vibrate the base material A evenly;

[0075] Step 3, making and fixing the capsule: preparing the flame-retardant capsule 20 and sequentially fixing the flame-retardant capsule 20 on the upper surface of the base material A in the mould;

[0076] Step 4. Ventilation and foaming: Inject carbon dioxide into the base material A in the mold, and let it stand for foaming:

[0077] Step 5, seal coating: after the foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com