Environment-friendly solid lubricating coating and preparation and using method thereof

A solid lubricating coating, an environmentally friendly technology, applied in coatings and other directions, to achieve the effect of huge application potential, simple preparation process, and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 0.6g of graphite, 0.4g of molybdenum disulfide and 0.68g of dispersant, pour the weighed sample into a ball mill jar, add 1g of deionized water, put in ceramic balls, and ball mill for 50 hours in total;

[0020] (2) Weigh 3g of water-based polyamide-imide and fully mix with the ground solid components, and fully stir to prepare a uniform and stable dispersed coating.

[0021] (3) Apply the paint evenly on the surface of the sample after degreasing and ultrasonic cleaning. The coated samples were left to dry at room temperature, and then cured at 280°C for 1 hour.

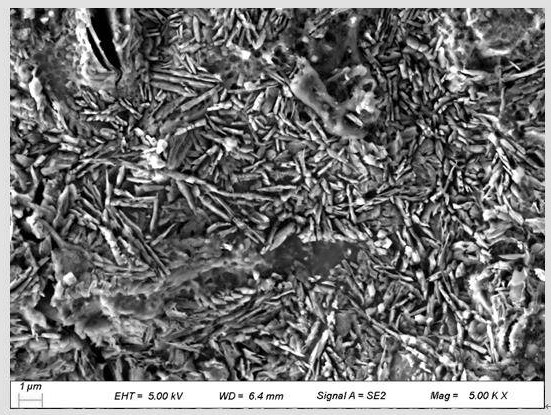

[0022] figure 1 Scanning electron micrograph of the solid lubricating coating prepared in Example 1 of the method of the present invention.

Embodiment 2

[0024] (1) Weigh 0.6g of graphite, 0.4g of molybdenum disulfide and 0.68g of dispersant, pour the weighed sample into a ball mill jar, add 1g of deionized water, put in ceramic balls, and ball mill for 50 hours in total;

[0025] (2) Weigh 3g of water-based polyamide-imide and fully mix with the ground solid components, and fully stir to prepare a uniform and stable dispersed coating.

[0026] (3) Apply the paint evenly on the surface of the sample after degreasing and ultrasonic cleaning. The coated sample was left to dry at room temperature, and then cured at 230°C for 1 hour.

Embodiment 3

[0028] (1) Weigh 0.6g of graphite, 0.4g of molybdenum disulfide and 0.8g of dispersant, pour the weighed sample into a ball mill jar, add 1g of deionized water, put in ceramic balls, and ball mill for 50 hours in total;

[0029] (2) Weigh 3g of water-based polyamide-imide and fully mix with the ground solid components, and fully stir to prepare a uniform and stable dispersed coating.

[0030] (3) Apply the paint evenly on the surface of the sample after degreasing and ultrasonic cleaning. The coated samples were left to dry at room temperature, and then cured at 280°C for 1 hour.

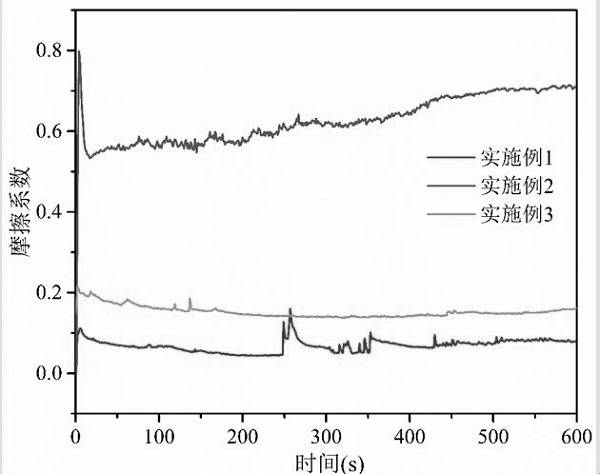

[0031] The model of the friction testing machine selected for the analysis of the tribological properties of the coating is MS-T3001. The friction ball made of GCr15 bearing steel is selected for the experiment, the hardness is 62HRC, the diameter of the steel ball is 6mm, the material of the steel sheet is 45# steel, and the radius of rotation is 5mm. Single sample test speed, load and time are 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com