Two yeasts for promoting production of lactic acid and phenolic acid and application thereof in brewing process of dry white wine

A dry white wine and yeast technology, which is applied in the preparation of wine, alcoholic beverages, and methods based on microorganisms, and can solve problems such as weak research and insufficient utilization of microbial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

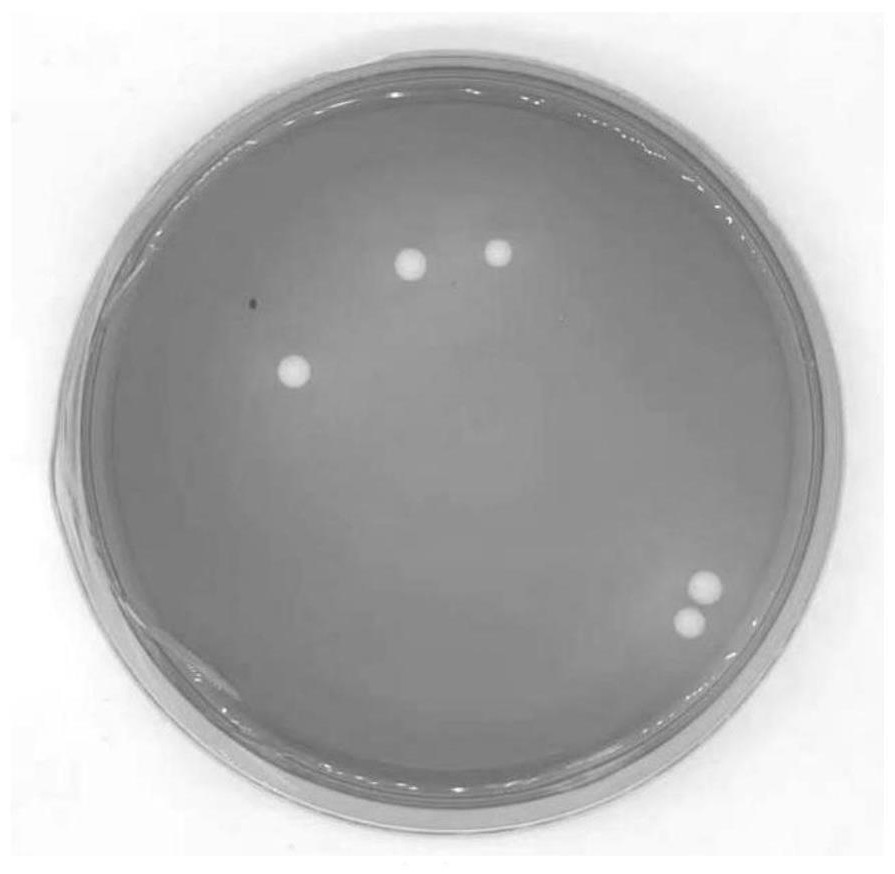

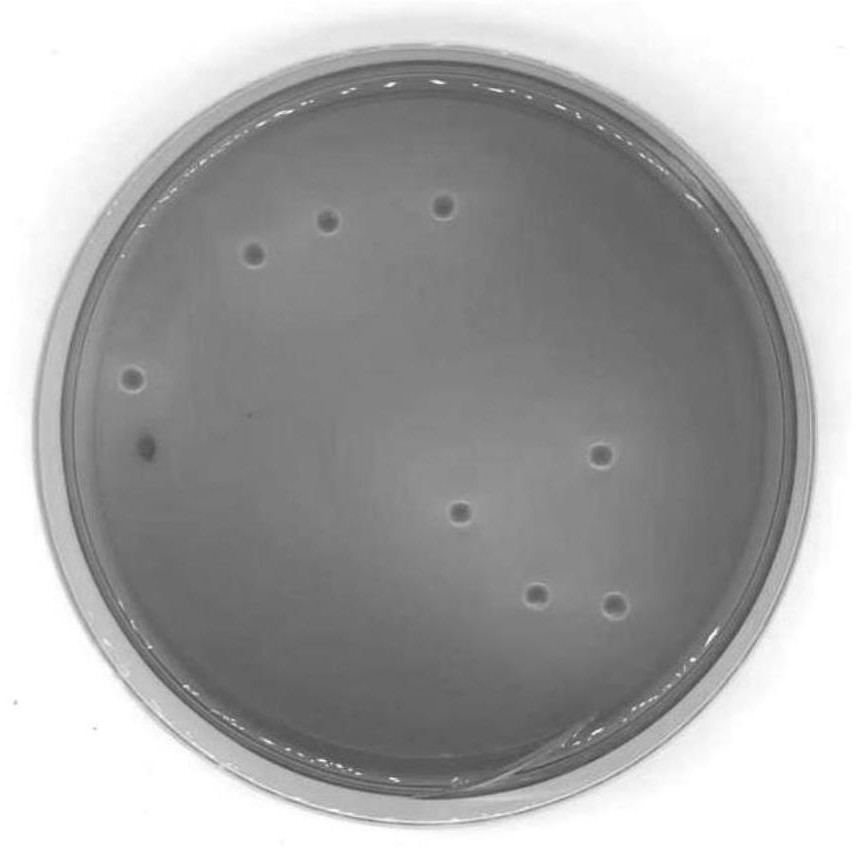

Image

Examples

Embodiment 1

[0028] Example 1 Small-scale test of sequential inoculation of yeast H30 and YT13 to ferment Guirenxiang dry white wine

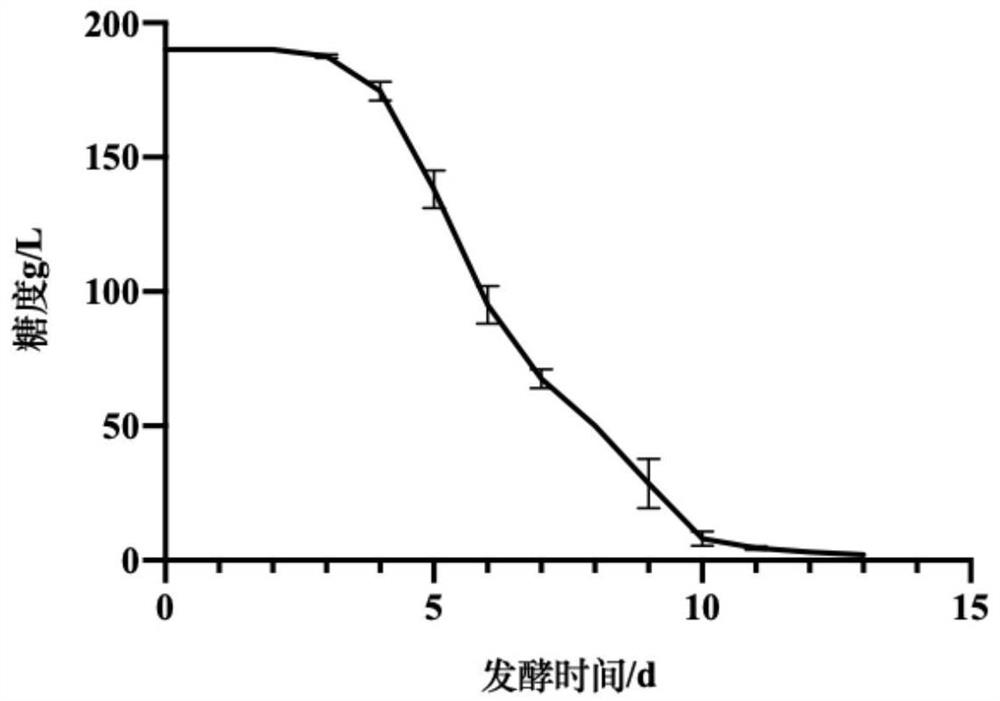

[0029] Destemming, crushing and crushing mature wine grapes of Guirenxiang variety, using a 10L glass fermenter as a wine fermentation container, using a commercial Saccharomyces cerevisiae EC1118 single-strain fermentation, Saccharomyces cerevisiae YT13 single-strain fermentation, H30 and commercial Saccharomyces cerevisiae sequential inoculation fermentation, H30 Sequentially inoculated and fermented with YT13, a total of four groups were set up with 3 parallels. After the yeast was activated, it was inoculated in YPD liquid medium, and cultured with constant temperature shaking at 28° C. for 18 hours under the condition of 120 rpm / min. The yeast was inserted into the clarified grape juice according to the inoculum amount of 1%, and fermented at 16°C. Carry out the detection and record of temperature, sugar content and specific gravity every day after st...

Embodiment 2

[0032] Example 2 Sequential inoculation of Yeast H30 and YT13 to ferment petite Manson dry white wine

[0033] Mature wine grapes of the Petit Mansen variety were destemmed, crushed and pressed, and a 10L glass fermenter was used as a wine fermentation vessel, using a commercial Saccharomyces cerevisiae EC1118 single-strain fermentation, Saccharomyces cerevisiae YT13 single-strain fermentation, H30 and commercial Saccharomyces cerevisiae sequential inoculation fermentation, H30 and YT13 were sequentially inoculated and fermented, and a total of four groups were set up in three parallels. After the yeast was activated, it was inoculated in YPD liquid medium, and cultured at 28°C for 18 hours with constant temperature and shaking. The single yeast liquid was inoculated into the clarified grape juice at an inoculation amount of 1%. The treatment group for sequential inoculation fermentation was first inoculated with H30, and commercial S. cerevisiae and YT13 were respectively ino...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap