Flexible electronic paper and preparation and application thereof

A kind of electronic paper and flexible technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of large overall thickness, small bending range, air bubbles, etc., and achieve the effect of reducing thickness, reducing cohesion, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the flexible electronic paper provided by the present invention comprises the following steps:

[0053] S1. Particles with a diameter of 200nm±20nm are screened out by a rotary wheel as color-developing particles.

[0054] S2. Put the chromogenic particles into the capsule solution, adjust the rotation speed of the runner to 200-300 rpm, and screen out electrophoretic display microcapsules with a particle size of 20 μm-30 μm.

[0055] S3. Inject the electrophoretic display microcapsules into the transparent conductive electrode to form a color-developing FPL (electronic paper ink film);

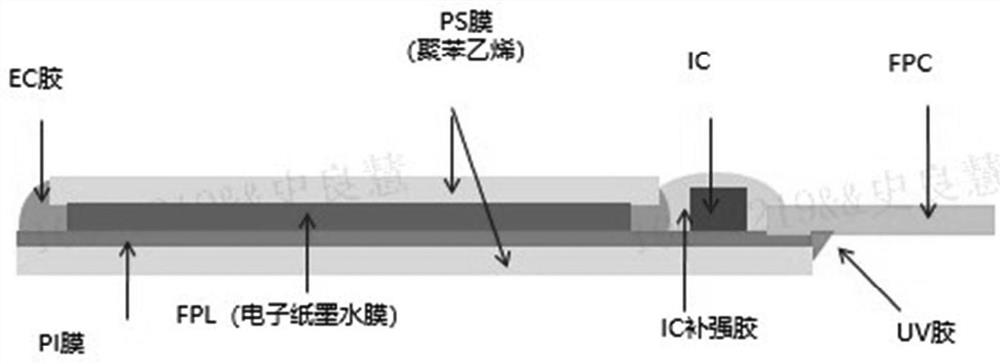

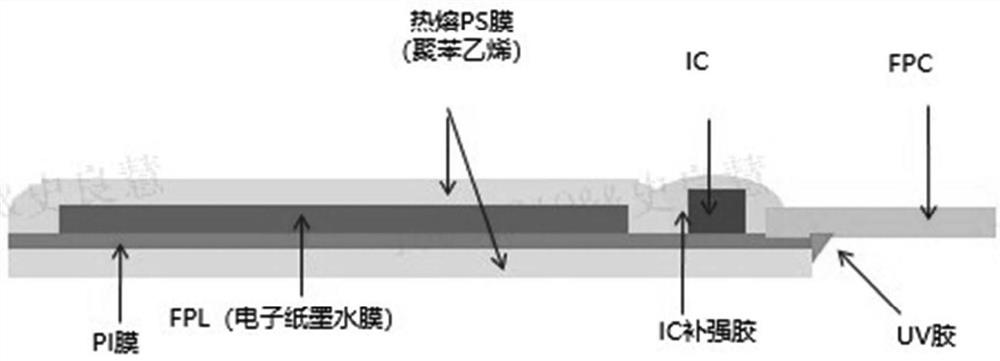

[0056] S4. Cut the color-developing FPL (electronic paper ink film) to the required size to prepare flexible electronic paper (EPD), including the following steps: glass cutting, FPL attachment, IC Bonding, FPC Bonding, PS attachment, PI separation , FPC serves as a bridge connecting the flexible electronic paper (EPD) and the motherboard. combine figure 2...

Embodiment 1

[0068] In order to achieve better flexibility, this embodiment optimizes and screens the particle size and shape of the chromogenic particles in the FPL and the electrophoretic display microcapsules.

[0069] The size of the chromogenic particles used in the FPL in the current flexible electronic paper is generally 200-300 nm, and the microcapsules displayed by electrophoresis are 50-100 μm.

[0070] In order to achieve better flexibility, faster refresh rate and better display effect, in this embodiment, the chromogenic particles are miniaturized and the electrophoretic display microcapsules are modified.

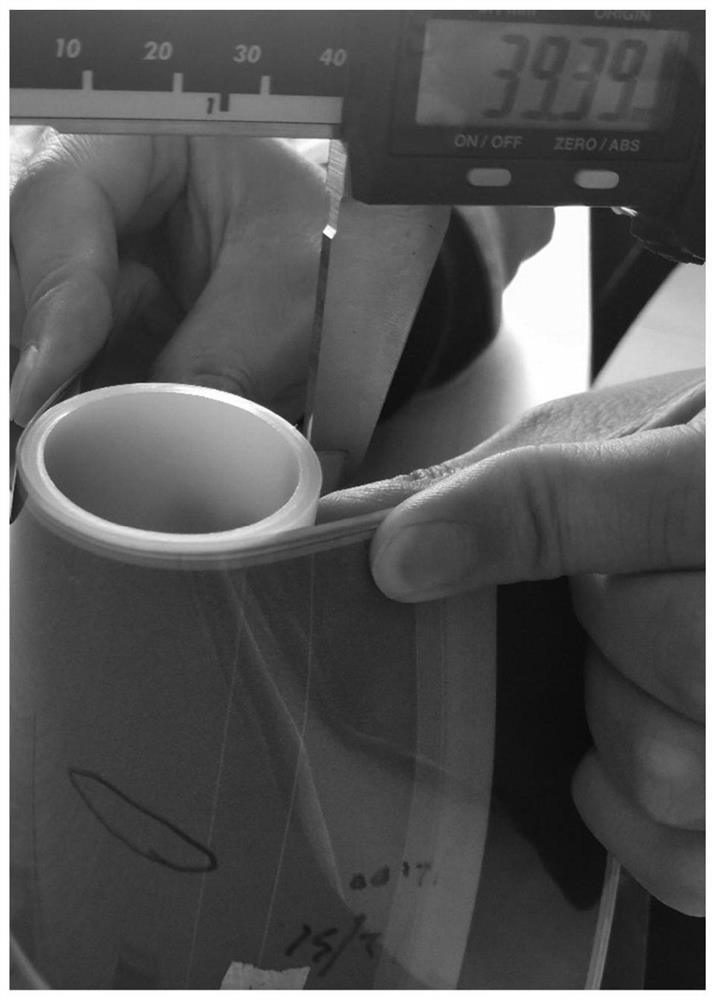

[0071] The size of the chromogenic particles is adjusted to about 200nm, and the particles of 200nm±20nm are specifically selected as chromogenic particles to enhance display clarity and improve uniformity. At the same time, the electrophoretic display microcapsules in the present invention are designed with spheres to increase the bending degree of the capsules. At the sa...

Embodiment 2

[0073] For the PS film, in this embodiment, the verification design is carried out for thinner materials, the thickness of the PS film is reduced from 256 μm to 125 μm, and the combination verification is carried out.

[0074] Experiments have proved that the PS film with a thickness of 125 μm can reduce the thickness of flexible electronic paper and increase its flexibility, while having no adverse effects on other materials, and can also play a protective role. Therefore, in order to improve the flexibility of the flexible electronic paper and ensure the protection effect, the present invention controls the thickness of the PS film within the range of 120-130 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com