Fireproof core material and manufacturing method

A manufacturing method and technology for fireproof cores, which are applied in the field of fireproof materials, can solve the problems of easy generation of flames, and the calorific value of fireproof core materials cannot meet the requirements of A2-level fireproof standards, achieve good flame retardancy and smoke suppression, reduce transportation and subsequent processing. cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

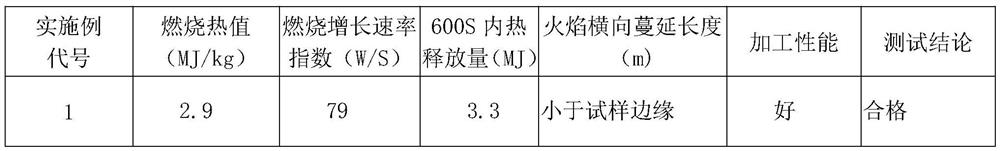

Embodiment 1

[0027] In the first step, in parts by weight, take 35 parts of the aqueous emulsion obtained by mixing styrene-acrylic and vinegar-acrylic acid, and 200 parts of inorganic flame-retardant powders composed of calcium carbonate powder particles with a maximum particle size of no more than 1000 μm. It is mixed and stirred to make a slurry. The calcium carbonate powder particles used in the slurry are heavy calcium carbonate powder or calcite powder, and the D50 particle size range is guaranteed by adjusting the D50 particle size ratio of the powder particles. The powder particles between 5 μm and 50 μm account for 90% of the total mass of the inorganic flame retardant powder, and the D50 particle size range of the remaining powder particles can be distributed between 100-400 μm;

[0028] In the second step, the slurry obtained in the first step is put into extrusion molding equipment to obtain a sheet;

[0029] In the third step, the sheets obtained in the second step are placed ...

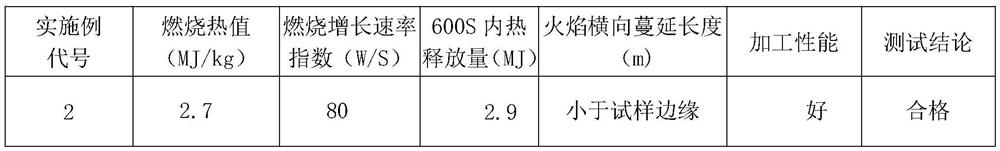

Embodiment 2

[0043] The first step, in parts by weight, takes 40 parts of vinyl acetate-ethylene copolymer aqueous emulsion (VAE emulsion), and 200 parts of inorganic flame-retardant powders composed of calcium carbonate powder particles with a maximum particle size of no more than 1000 μm, in a vacuum It is mixed and stirred under certain conditions to make a slurry. The calcium carbonate powder particles used in the slurry are heavy calcium carbonate powder or calcite powder, and the D50 particle size ratio of the powder particles is adjusted to ensure that the D50 particle size The powder particles within the range of 5 μm to 50 μm account for 20% of the total mass of the inorganic flame retardant powder, and the D50 particle size range of the remaining powder particles can be distributed between 100-400 μm;

[0044] In the second step, the slurry obtained in the first step is put into extrusion molding equipment to obtain a sheet;

[0045] In the third step, the sheets obtained in the ...

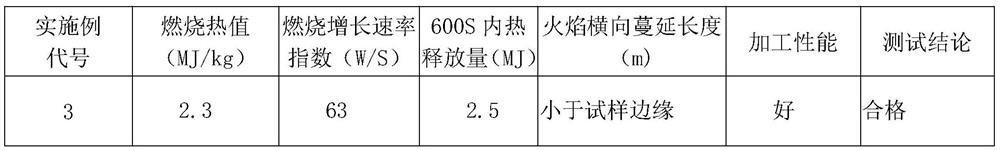

Embodiment 3

[0061] The first step, in parts by weight, takes 45 parts of acrylic acid aqueous emulsion, and 100 parts of fine-grained calcium carbonate powder with a D50 particle size range of 5-50 μm, and 10 parts of D50 particle size range between 5-400 μm 200 parts of inorganic flame retardants composed of a mixture of aluminum hydroxide powder, magnesium hydroxide powder, and 90 parts of coarse-grained calcium carbonate powder with a D50 particle size range of 100-400 μm, were mixed under vacuum conditions Mix and stir to make a slurry. The powder particles of aluminum hydroxide and magnesium hydroxide used in the slurry can be selected at the same time: coarse aluminum hydroxide powder, which is made by Bayer process, and its D50 particle size range Between 100 μm and 400 μm; fine-grained aluminum hydroxide powder, which is made by sintering process, and its D50 particle size range is between 5 μm and 50 μm; fine-grained magnesium hydroxide powder, which is made by ore method, its D50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com