Artificial stone based on deposition method and CO2 driven consolidation and preparation method thereof

A technology of CO2 and artificial stone, applied in the field of artificial stone, can solve the problem that artificial stone cannot take into account weather resistance and flexural strength, etc., and achieve good environmental protection benefits, simple process, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

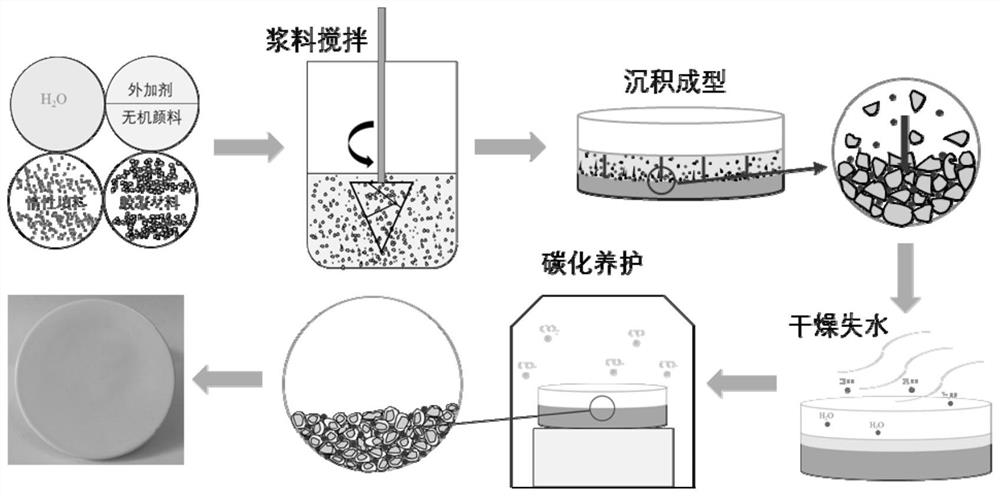

[0031] see figure 1 , the second aspect of the present invention provides a method based on deposition and CO 2 A method for preparing a driven-solidified artificial stone, comprising the following steps:

[0032] Mix the multi-grade powder with water evenly to make a slurry;

[0033] Allow the slurry to stand and deposit to form a green body, and carbonize and maintain the green body to form an artificial stone with calcium carbonate as the matrix.

[0034] In the present invention, the step of uniformly mixing the multi-graded powder with water to make a slurry is specifically: uniformly mixing the gelling material, inert filler, and inorganic pigment to obtain a dry material, dissolving the admixture in water and then stirring to dry material and mix evenly into a paste.

[0035] In the present invention, a mold with a smooth surface is selected to make the surface of the formed artificial stone smooth.

[0036] In the present invention, the material of the mold is one ...

Embodiment 1

[0046] Embodiment 1 provides a method based on deposition and CO 2 A method for preparing a driven-solidified artificial stone, comprising the following steps:

[0047] (1) 180 parts of γ-C 2 S. Mix 20 parts of limestone powder evenly, dissolve 1.2 parts of chitin in 80 parts of water, stir the dry material and evenly mix it into a slurry;

[0048] (2) Put the slurry in the mold and let it stand for 12 hours, remove the supernatant, and place the green body in a 40°C oven to dry until the remaining water-solid ratio is 0.04;

[0049] (3) Place the dried green body in a carbonization reaction kettle for carbonization to obtain artificial stone; wherein, the carbonization conditions are: the carbonization curing temperature is 25°C, the relative humidity is 50%, the carbon dioxide concentration is 99.8%, and the air pressure is 0.3 MPa, carbonization time is 12h.

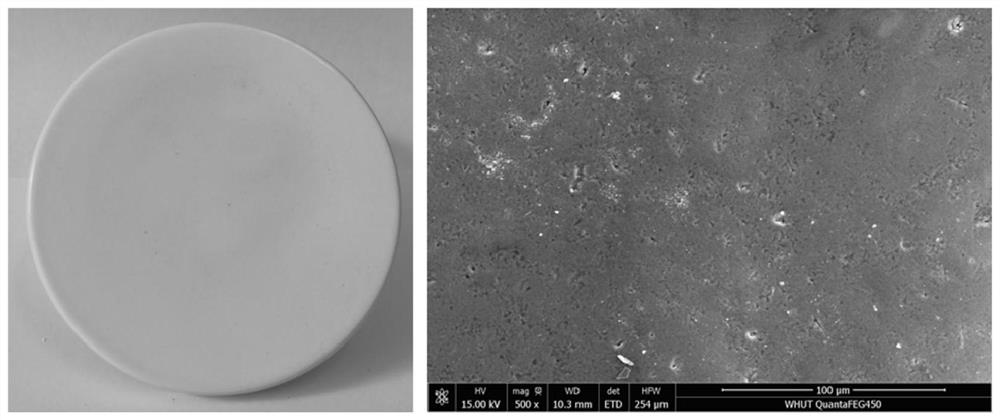

[0050] The obtained artificial stone of embodiment 1 is as figure 2 It can be seen from the scanning electron ...

Embodiment 2

[0052] Embodiment 2 provides a method based on deposition and CO 2 A method for preparing a driven-solidified artificial stone, comprising the following steps:

[0053] (1) Mix 80 parts of γ-C 2 S. Mix 20 parts of quartz sand evenly, dissolve 0.4 parts of polyvinyl alcohol in 40 parts of water, mix the dry material and evenly mix it into a slurry;

[0054] (2) Put the slurry in the mold and let it stand for 12 hours, remove the supernatant, and place the green body in a 40°C oven to dry until the remaining water-solid ratio is 0.04;

[0055] (3) Place the dried green body in a carbonization reaction kettle for carbonization to obtain artificial stone; wherein, the carbonization conditions are: the carbonization curing temperature is 25°C, the relative humidity is 50%, the carbon dioxide concentration is 99.8%, and the air pressure is 0.3 MPa, carbonization time is 12h.

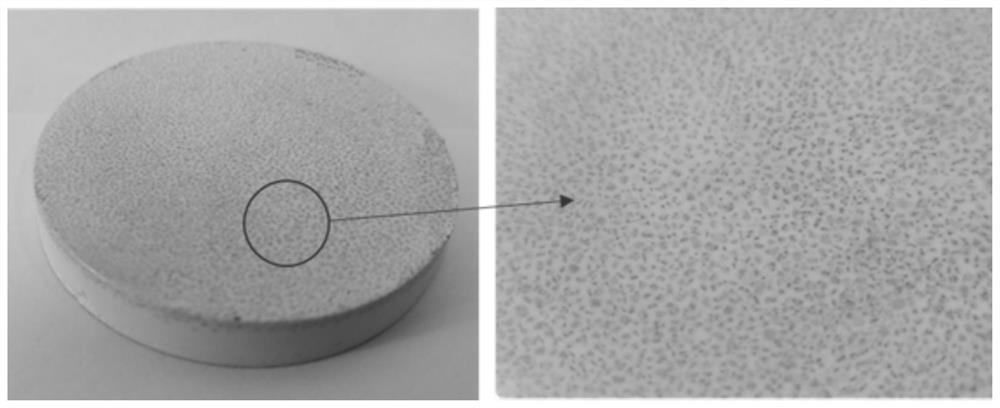

[0056] The obtained artificial stone of embodiment 2 is as image 3 As shown, its compressive strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com