Preparation method for mode field conversion coupling structure and preparation structure of the mode field conversion coupling structure

A technology of coupling structure and mode field conversion, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of high structural processing precision, low wavelength sensitivity, and reduced production efficiency, and achieve large processing size and high process efficiency. Simple, avoid high roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

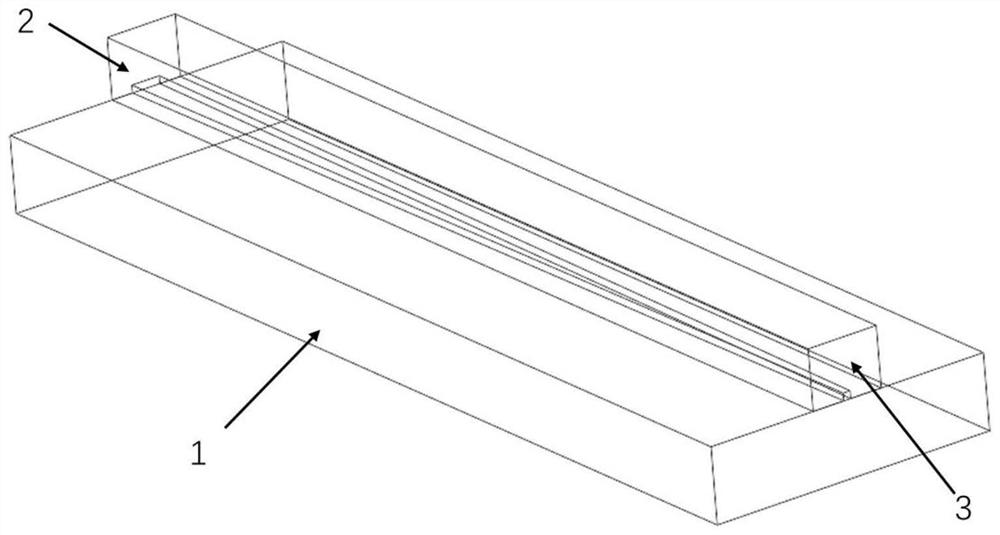

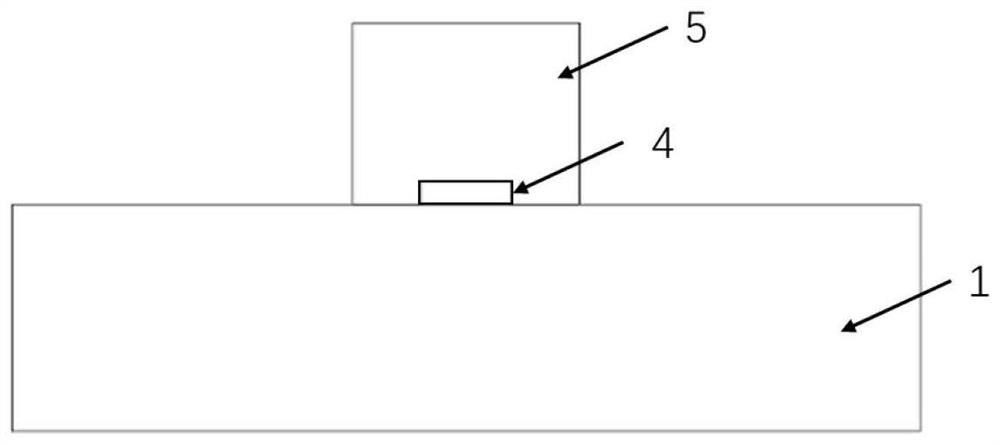

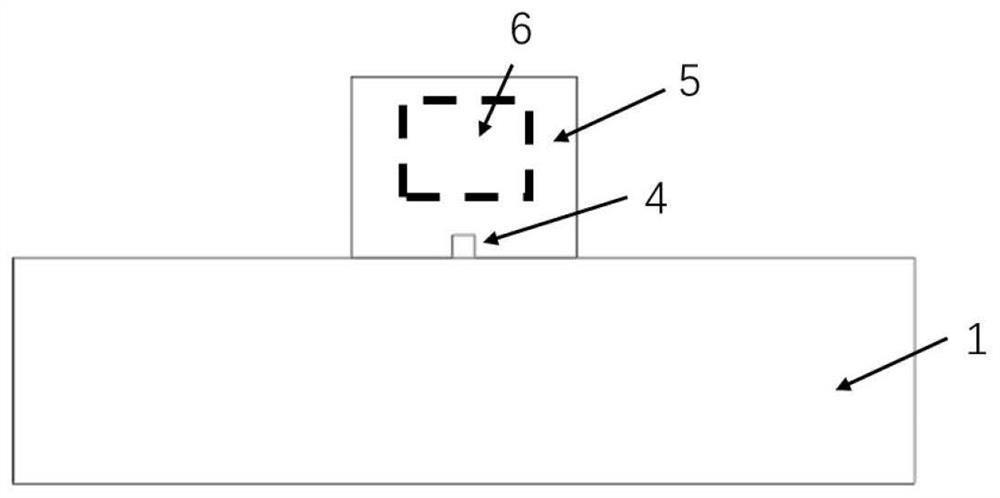

[0047] In order to better understand the present invention, the present invention will be described in further detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0048] Taking a lithium niobate on insulator (LNOI) photonic chip as an example, the waveguide on the chip has a width of 1 μm and a thickness of 500 nm. A 100 μm thick polyethylene film was used as a cover, exposing only the 300 μm long end of the waveguide. Use golden velvet polishing cloth and silica ball polishing liquid with a particle size of 20nm as the polishing liquid. Polishing at a rotating speed of 50r / min and a polishing time of 4min can realize a tapered waveguide structure with a length of 300μm and a terminal thickness and width close to 0. The relationship between polishing time and the size of the tapered structure is shown in the table below.

[0049] polishing time Conical structure length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com