Preparation method of copper-niobium composite radio frequency superconducting resonant cavity

A technology of superconducting resonant cavity and superconducting cavity, which is applied in the direction of waveguide devices, accelerators, circuits, etc., can solve the problems of superconducting cavity purity control and difficult control of weld bead recombination, and achieve good mechanical strength and high bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Taking a spoke (Spoke) superconducting cavity with a frequency of 325 MHz as an example, the preparation method of the copper-niobium composite superconducting cavity involved in the present invention is described. Specific steps are as follows:

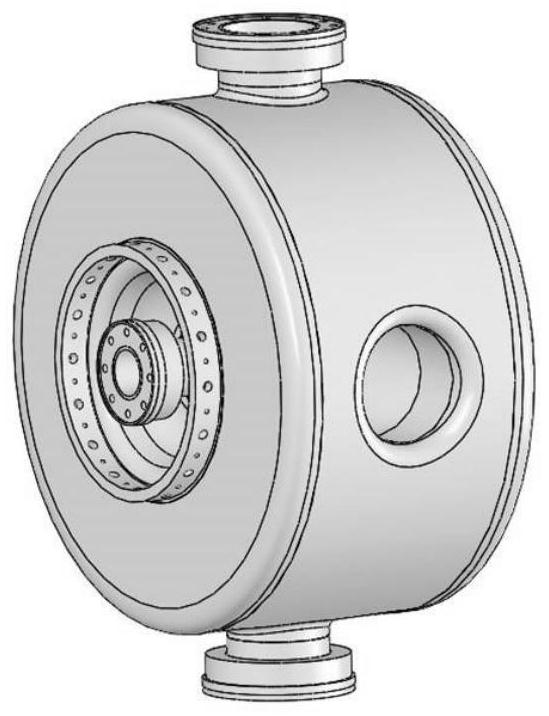

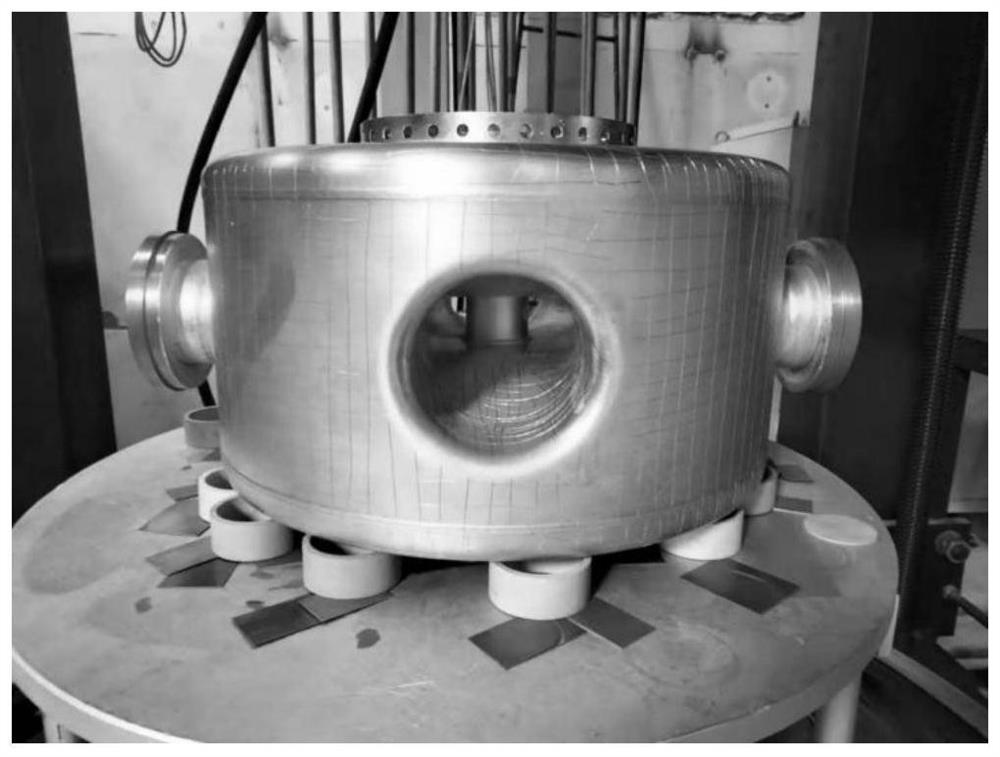

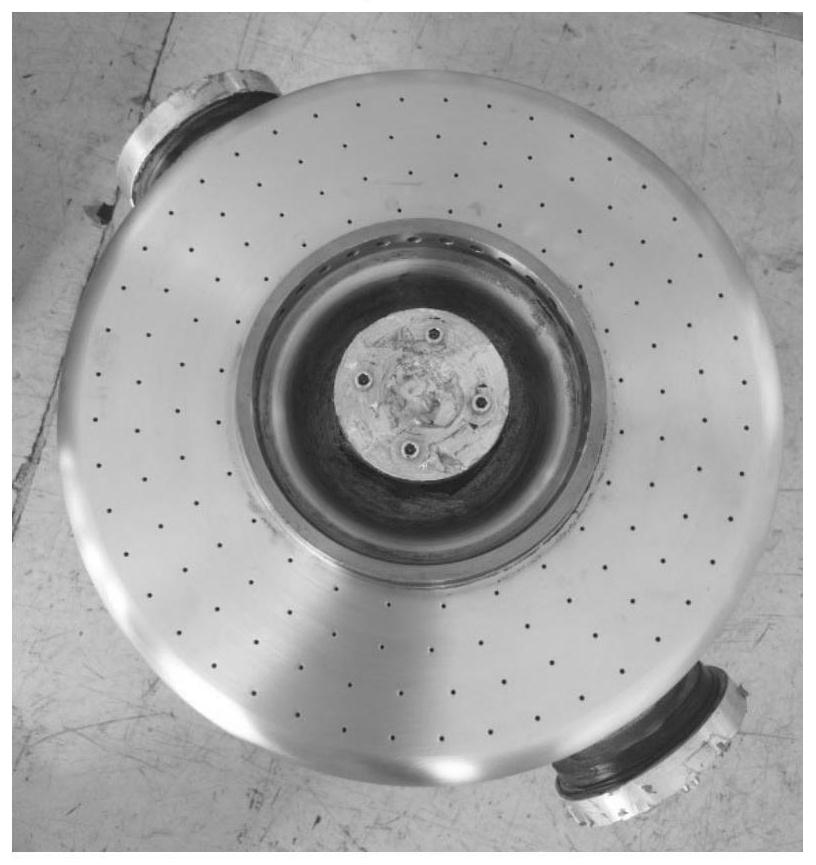

[0043] 1) Development of the Spoke pure niobium superconducting cavity: process a Spoke superconducting cavity with a wall thickness of 3 mm and a frequency of 325 MHz according to the standard processing specification for pure niobium superconducting cavity, as shown in the schematic diagram figure 1 shown;

[0044]2) Surface treatment inside and outside the Spoke pure niobium superconducting cavity: 1) Mechanical polishing; 2) Cleaning with alcohol, acetone and other cleaning liquids; 3) 50-minute ultrasonic ultrapure water cleaning to remove the grease on the surface of the material, wherein the resistivity during the ultrasonic cleaning process is The temperature of the 18.2MΩ*cm ultrapure water and cleaning agent mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com