Blueberry and blackberry juice solidified bean curd and production method thereof

A production method and technology of blackberry juice, which is applied in the field of deep processing of soybean products, can solve the problems of single product variety, taste and flavor, uneven solidification of soybean protein, and uneven texture of tofu, so as to achieve the function of nutrition and health care and solve the variety of tofu products The effect of single taste and flavor, avoiding chemical and biological safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

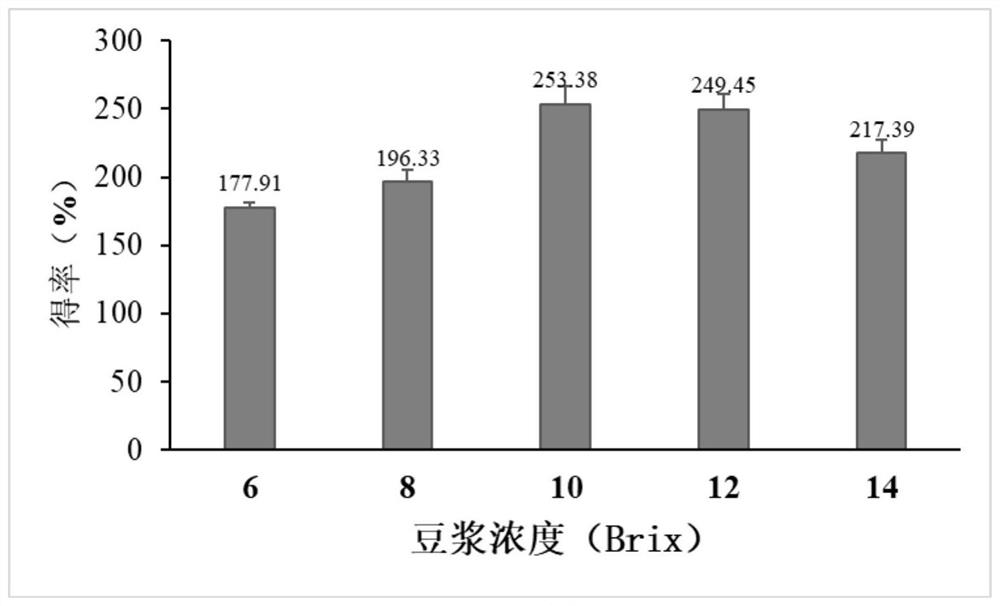

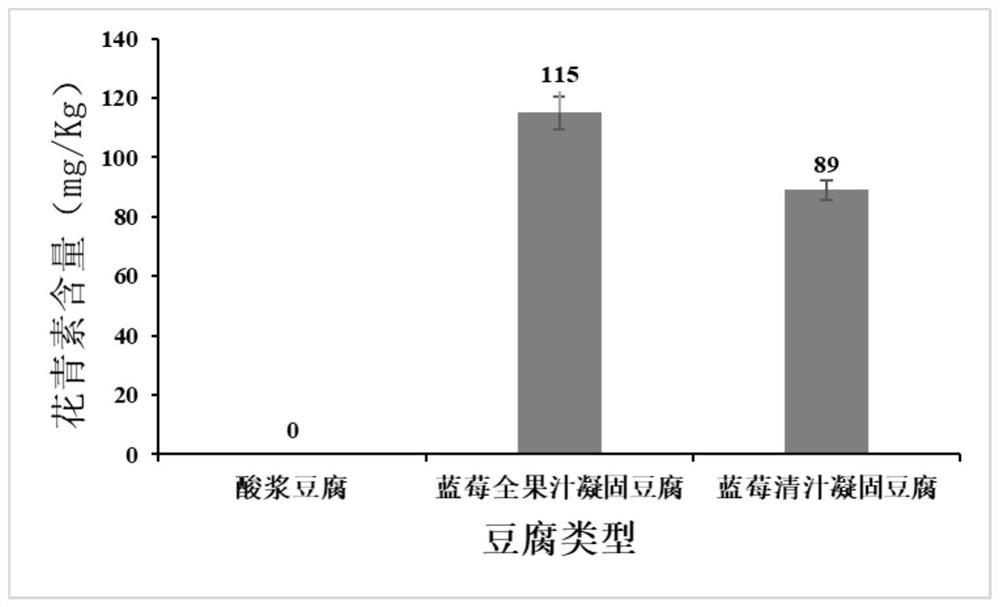

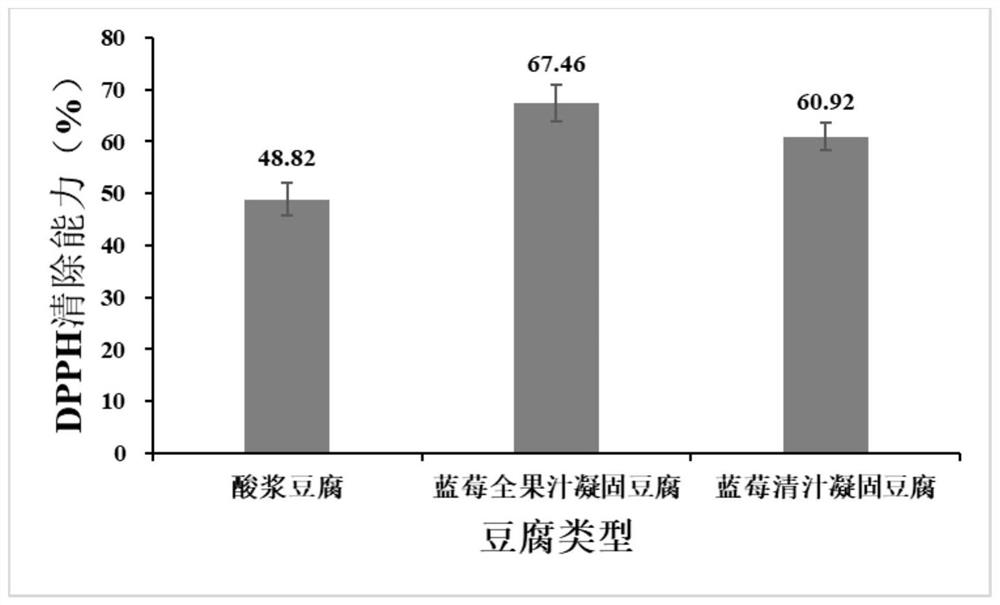

[0041] First, the soybeans are cleaned of impurities and soaked in water until there is no solid. Before refining, add water to the soybean-water mass ratio of 1:6. After refining and separating pulp and residue, 10 Brix raw soybean milk is obtained. The raw soybean milk is heated to boiling and maintained for 5 After 10 minutes, cooked soya-bean milk is obtained. At the same time, the ripe and fresh blueberry fruit is selected, crushed to obtain the whole blueberry juice, and the whole blueberry juice is diluted with water to 5 times the volume and then heated to 50°C.

[0042] In the case of maintaining the temperature of the cooked soybean milk at 85°C, first add the diluted blueberry juice to the cooked soybean milk at a uniform speed within 10 seconds, and at the same time slowly stir in the same direction until the phenomenon of broken flowers appears , and then continue to add the whole blueberry juice within 1 minute, and the pH of the slow stirring system reaches 5.5....

Embodiment 2

[0044] First remove impurities from the soybeans, wash them, soak them in water until they are solid, add water before refining to a soybean-to-water ratio of 1:6, and obtain 10 Brix raw soybean milk after refining and separating pulp and residue, heat the raw soybean milk to boiling steam and maintain it for 5 minutes Obtain cooked soya-bean milk afterwards. At the same time, select ripe and fresh blueberries, crush them to obtain whole blueberry juice, centrifuge at 5000 rpm for 10 minutes, take the supernatant to obtain clear blueberry juice, dilute the clear blueberry juice with water to 3 times its volume, and heat it to 55°C.

[0045] In the case of maintaining the temperature of the cooked soybean milk at 85°C, first add the diluted blueberry juice to the cooked soybean milk at a uniform speed within 15 seconds, add blueberry juice with 5% of the volume of the soybean milk, and stir slowly in the same direction until it appears broken Flower phenomenon, continue to add ...

Embodiment 3

[0047] First remove impurities from the soybeans, wash them, soak them in water until they are solid, add water to the ratio of soybean water to 1:4 before refining, and obtain 12 Brix raw soybean milk after refining and separating the soybean dregs, heat the raw soybean milk steam to boiling and maintain it for 10 minutes Obtain cooked soybean milk. At the same time, the ripe and fresh blueberry fruit is selected, crushed to obtain the whole blueberry juice, and the whole blueberry juice is diluted with water to 5 times the volume and then heated to 55°C.

[0048] In the case of maintaining the temperature of the cooked soybean milk at 85°C, first add the diluted blueberry juice to the cooked soybean milk at a uniform speed within 15 seconds, and add blueberry juice with a volume of 7.5% of the soybean milk, and at the same time stir slowly in the same direction until it becomes broken flowering phenomenon, continue to add coagulant within 2 minutes, and slowly stir until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com