Preparation method and application of rare earth vanadate two-dimensional nanosheet photocatalytic material

A rare-earth vanadate and two-dimensional nanotechnology, which is applied in the preparation/separation of ammonia, chemical instruments and methods, and catalysts for physical/chemical processes, etc., to achieve small band gap, excellent performance, and favorable light penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 100mL of Sm(NO 3 ) 3 ·6H 2 O and NH 4 VO 3 Mix in deionized water (both concentrations are 0.001mol / L), ultrasonicate until completely dissolved, add 0.001mol organic template polyvinylpyrrolidone under heating and magnetic stirring conditions, and adjust the pH of the solution to 1 with hydrochloric acid, and then mix the solution Transfer to a sealed Teflon autoclave and react at 120°C for 2 hours under microwave hydrothermal conditions. After naturally cooling to room temperature, the resulting precipitate was collected by centrifugation and washed several times with deionized water. Finally, dry at 80°C for 12 hours to obtain SmVO 4 Two-dimensional nanosheet materials.

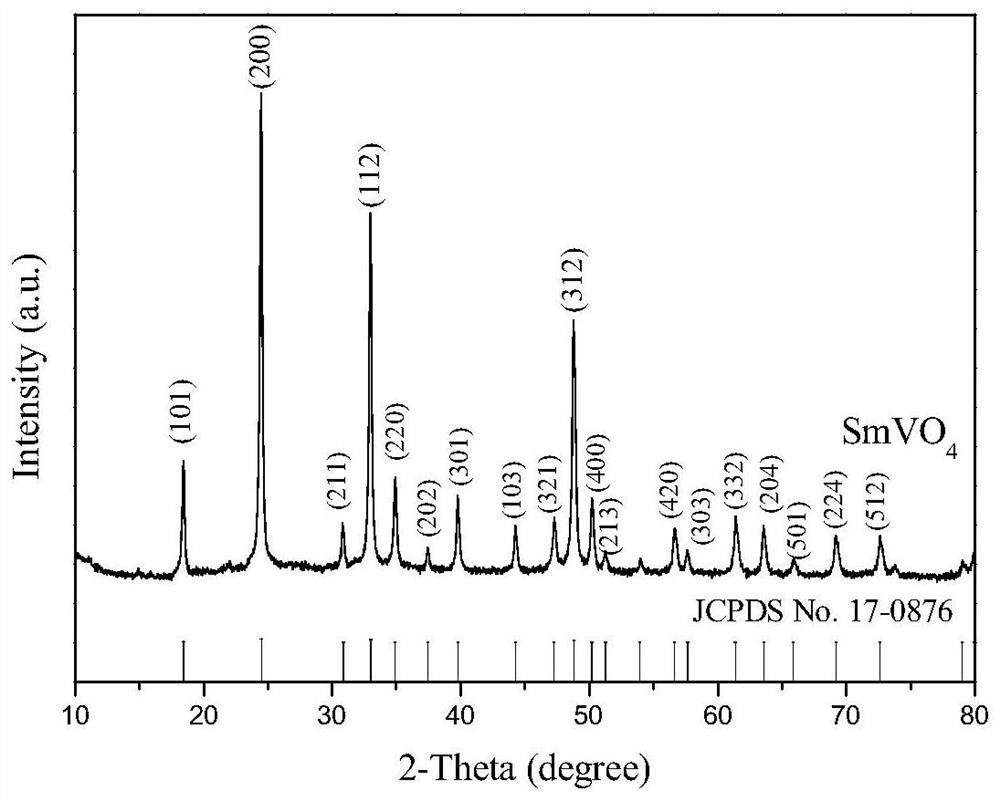

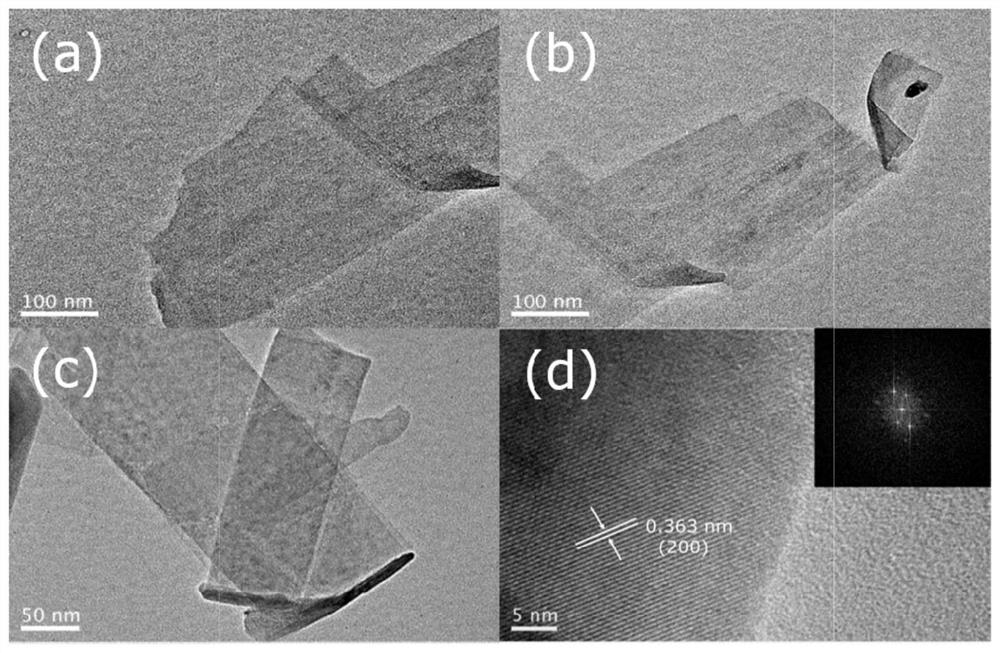

[0027] figure 1 is SmVO 4 The XRD patterns and SmVO 4 PDF card (JCPDS No.17-0876). It can be seen from the figure that the three strong peaks at 2θ = 24.9°, 33.2°, 48.6° correspond to SmVO 4 The (200), (112), (312) planes determine the SmVO 4 the existence of species. In addition, there...

Embodiment 2

[0032] 100mL of Ce(NO 3 ) 3 ·6H 2 O and NH 4 VO 3Mix in deionized water (both concentrations are 0.1mol / L), ultrasonicate until completely dissolved, add 0.01mol organic template polyvinylpyrrolidone under heating and magnetic stirring conditions, and adjust the pH of the solution to 4 with nitric acid, and then mix the The solution was transferred to a sealed Teflon autoclave, and reacted for 1 hour under the condition of microwave hydrothermal heating at 180°C. After naturally cooling to room temperature, the resulting precipitate was collected by centrifugation and washed several times with deionized water. Finally, dry at 80°C for 12 hours to obtain CeVO 4 Two-dimensional nanosheet materials.

[0033] The invention also provides the above material for photocatalytic synthesis of ammonia. Under full-spectrum irradiation of 300W xenon lamp, CeVO 4 The ammonia yield of nanosheets reached 116umolg -1 h -1 , under the irradiation of near-infrared light after 780nm, Ce...

Embodiment 3

[0035] 100mL of Pr(NO 3 ) 3 ·6H 2 O and NH 4 VO 3 Mix in deionized water (both concentrations are 0.01mol / L), ultrasonicate until completely dissolved, add 0.005mol organic template polyvinylpyrrolidone under heating and magnetic stirring conditions, and adjust the pH of the solution to 3 with nitric acid, and then mix the The solution was transferred to a sealed Teflon autoclave, and reacted for 1.5 hours under the condition of microwave hydrothermal heating at 140°C. After naturally cooling to room temperature, the resulting precipitate was collected by centrifugation and washed several times with deionized water. Finally, dry at 80°C for 12 hours to obtain PrVO 4 Two-dimensional nanosheet materials.

[0036] The invention also provides the above material for photocatalytic synthesis of ammonia. Under the full spectrum irradiation of 300W xenon lamp, PrVO 4 The ammonia yield of nanosheets reached 112umolg -1 h -1 , under the irradiation of near-infrared light after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com