Composite membrane as well as preparation method and application thereof

A composite film and release film technology, applied in the field of composite materials, can solve the problems of cumbersome construction steps, poor adhesion of ordinary glue and adhesive, and tight adhesion of decorative films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

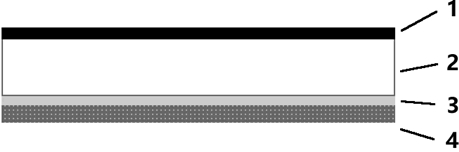

[0184] This embodiment discloses a composite membrane, and the structural schematic diagram of the composite membrane is as follows figure 1 As shown, it is formed by laminating four layers, which are the adhesive layer 1, the polypropylene substrate layer 2, the connection layer 3 and the release BOPET layer 4 in sequence.

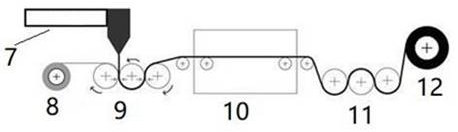

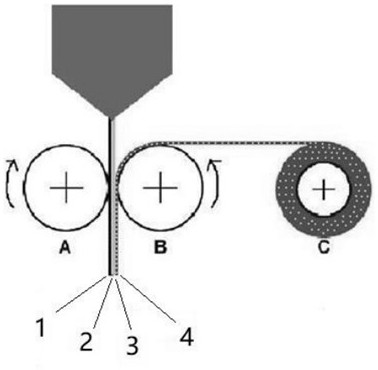

[0185] The preparation process of described composite film comprises:

[0186] (I) Preparation of adhesive layer materials: Weigh the raw materials of each component of the adhesive layer according to the composition ratio in Table 1, and put them into a high-speed mixer for homogeneous mixing. The speed of the mixer is 1400r / min, and the mixing time is 0.6min. Then the raw material mixture was put into a twin-screw extruder for melt kneading and extrusion, and the extrusion temperature was 190°C. The extruded samples were cooled and pelletized for later use.

[0187] Preparation of polypropylene substrate layer materials: Weigh the raw materials of ea...

Embodiment 2

[0200] This embodiment discloses a composite membrane, and the specific preparation process includes:

[0201] (I) Preparation of adhesive layer materials: Weigh the raw materials of each component of the adhesive layer according to the composition ratio in Table 2, and put them into a high-speed mixer for homogeneous mixing. The speed of the mixer is 1000r / min, and the mixing time is 1min. Then the raw material mixture was put into a twin-screw extruder for melt kneading and extrusion, and the extrusion temperature was 210°C. The extruded samples were cooled and pelletized for later use.

[0202] Preparation of polypropylene substrate layer materials: Weigh the raw materials of each component of the polypropylene substrate layer according to the composition ratio in Table 2, and put them into a high-speed mixer for homogeneous mixing. The speed of the mixer is 1800r / min, and the mixing time is 1min. Then the raw material mixture was put into a twin-screw extruder for melt ...

Embodiment 3

[0214] This embodiment discloses a composite membrane, and the specific preparation process includes:

[0215] (I) Preparation of adhesive layer materials: Weigh the raw materials of each component of the adhesive layer according to the composition ratio in Table 3, and put them into a high-speed mixer for homogeneous mixing. The speed of the mixer is 1200r / min, and the mixing time is 0.8min. Then the raw material mixture is put into a twin-screw extruder for melt kneading and extrusion, and the extrusion temperature is 170°C. The extruded samples were cooled and pelletized for later use.

[0216] Preparation of polypropylene substrate layer materials: Weigh the raw materials of each component of the polypropylene substrate layer according to the composition ratio in Table 3, and put them into a high-speed mixer for homogeneous mixing. The speed of the mixer is 1600r / min, and the mixing time is 0.5min. Then the raw material mixture is put into a twin-screw extruder for melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Release force | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com