Foamable material for supporting packaging structure and preparation method of foamable material

A technology of packaging structure and foaming agent, applied in the field of styrofoam, which can solve the problems of colloids that are not easy to degrade, environmentally unfriendly, and lack of buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

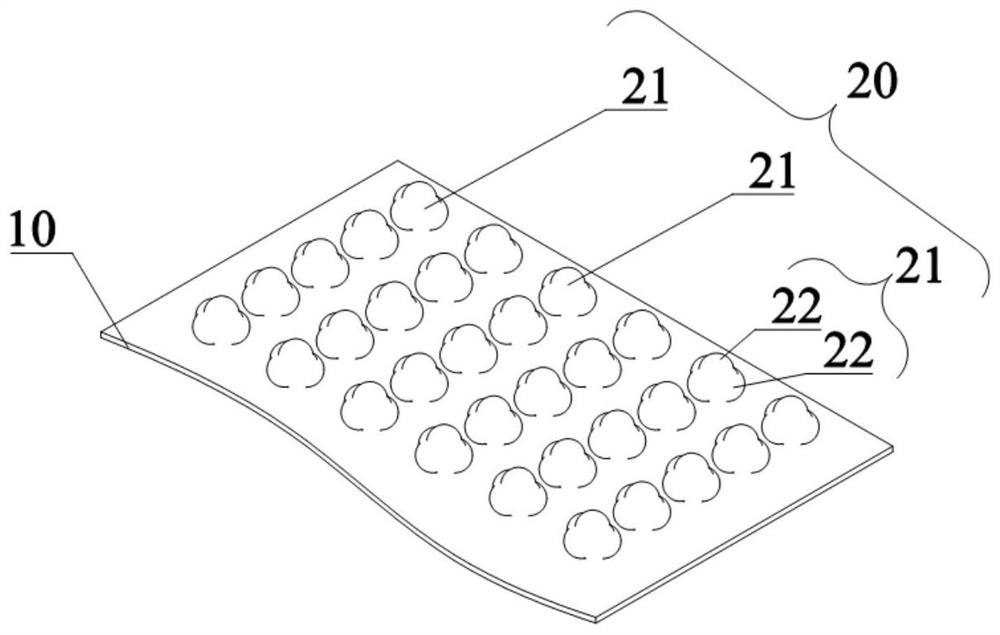

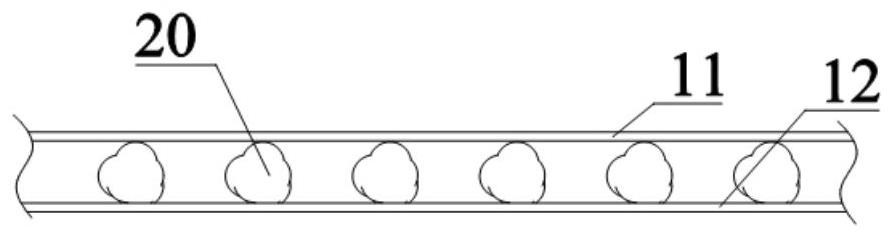

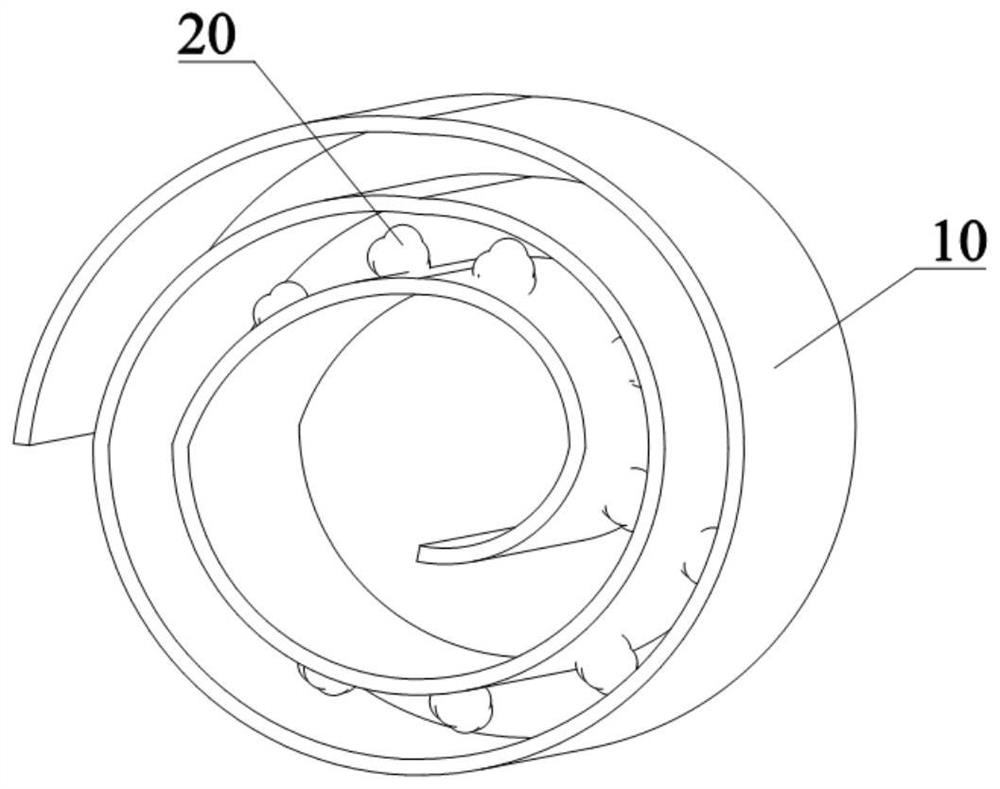

Image

Examples

Embodiment 1

[0044] The foaming emulsion in the present embodiment 1 is based on 98 g of water-based polymer emulsion, and the polymer emulsion is water-based acrylate emulsion (Acronal V206 acrylate emulsion of BASF). The requirement for the polymer resin emulsion is that the polymer needs to have certain flexibility after drying, and its glass transition temperature should be lower than 40°C.

[0045] The present invention discovers the relationship between matrix emulsion, glass transition temperature lower than 40 DEG C, and flexibility, and then applies it to styrofoam products. Also, usually the role of flexibility is to play a role in the bag's resistance to deformation when stretched, when the bag is stacked, or when there is rubbing. The difference from the elastic properties is that the action time of the elastic deformation is prolonged, that is, it can be considered that the flexibility is exerted, which makes the structural stability of the bag stronger. For example, the elas...

Embodiment 2

[0050] In this embodiment 2, the foaming emulsion is based on 120 g of water-based high molecular polymer emulsion, which is a compound of 80 g of DA101 vinyl acetate-ethylene copolymer of Dalian Chemical and 40 g of U54 polyurethane emulsion of Bayer. The requirement for the compounded polymer resin emulsion is that the polymer needs to have certain flexibility after drying, and its glass transition temperature should be lower than 5°C.

[0051] 11g of foaming powder that can be heated and foamed is added to the foaming emulsion. The foaming powder includes polymers that are foamed microspheres containing alkane gas inside the shell, such as Aksu’s Expancel series of foamed microspheres, Shanghai Tuojia foaming microsphere series, Japan Sekisui foaming microsphere series, American Polychem foaming microsphere series, etc.; there is also AC foaming agent of azodicarbonamide. The foaming temperature of the foamed microspheres or foamed powder of the present invention needs to b...

Embodiment 3

[0055] In the present embodiment 3, the foaming emulsion is based on 108 g of water-based polymer emulsion, which is 50 g of Acronal V206 acrylate emulsion of BASF, 30 g of U54 polyurethane emulsion of Bayer, and 28 g of SD417 styrene-butadiene emulsion of BASF. The requirement for the compounded polymer resin emulsion is that the polymer needs to have certain flexibility after drying, and its glass transition temperature should be lower than 2°C.

[0056] 8g of foaming powder that can be heated and foamed is added to the foaming emulsion. The foaming powder includes polymers that are foamed microspheres containing alkane gas inside the shell, such as Aksu’s Expancel series of foamed microspheres, Shanghai Tuojia foaming microsphere series, Japan Sekisui foaming microsphere series, American Polychem foaming microsphere series, etc.; there is also AC foaming agent of azodicarbonamide. The foaming temperature of the foamed microspheres or foamed powder of the present invention n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com