Ethylene-propylene-diene monomer rubber and method for casting electric power trench at one time by adopting same

A EPDM rubber, one-off technology, applied in the direction of buildings, artificial islands, underwater structures, etc., can solve the problem of affecting the safety of the waterproof performance of power trenches, improper use and installation of waterproof tapes, affecting the integrity of power trenches, etc. It can improve the waterproof effect and safety, save the maintenance cost and improve the overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

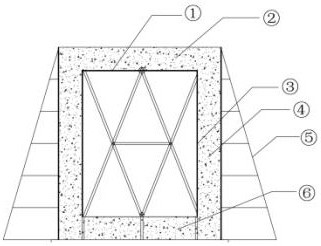

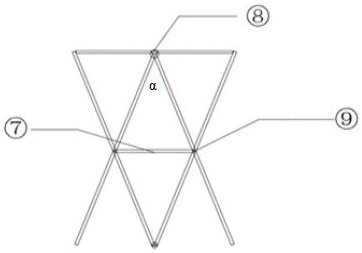

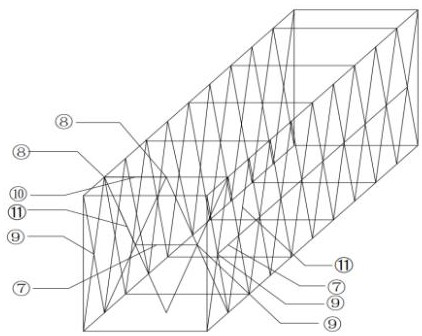

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only for illustration, and are not intended to limit the present application.

[0041] In this embodiment, in order to shorten the construction period and improve the integrity and waterproof and imperviousness of the structure, the concrete pouring adopts the method of one-time pouring and continuous pouring from one end to the other end. When pouring, adopt the method of longitudinal segmentation and vertical layering construction. The length of the longitudinal segmentation is divided into a pouring section according to 30m in principle. For each section, the bottom slab concrete and 30cm high wall are poured first, and then the remaining wall and roof are poured.

[0042]The overall flow of the construction process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com