Loose metal sintering layer section observation method and ion grinding device

A metal sintering and cross-section technology, applied in metal processing equipment, grinding devices, grinding machine tools, etc., can solve the problems of inability to observe the degree of dispersion of the catalytic body from the cross-section, the separation of the surface catalytic body from the carrier plate, and the reduction of the convenience of the catalytic body. , to achieve the effect of improving convenience, improving grinding quality and efficiency, and reducing the probability of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

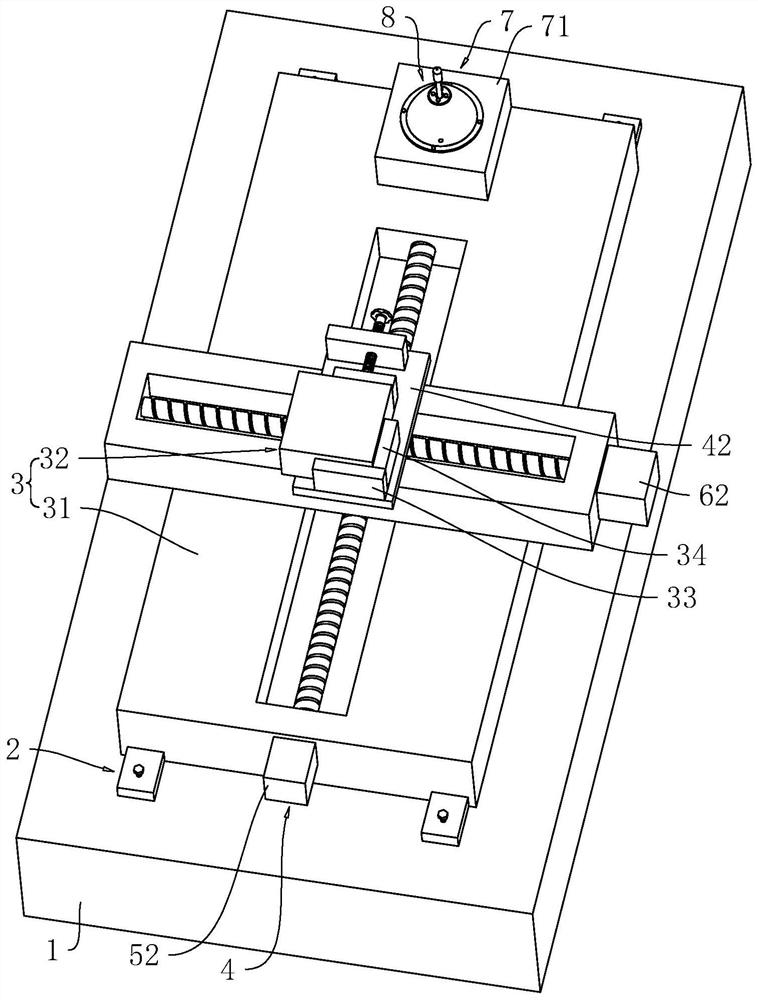

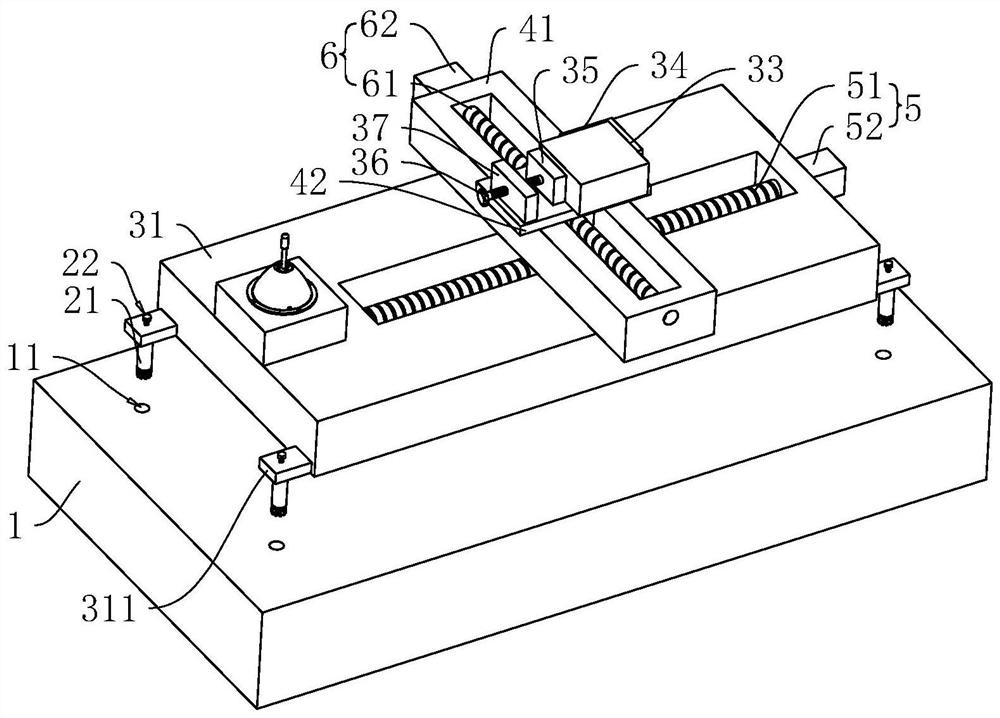

[0076] refer to figure 1 , the cross-section observation method of loose metal sintered layer, comprises the following steps:

[0077] S1. Clamp the sample to the fixture 3, and the upper surface of the sample protrudes from the fixture 3. The fixture 3 has a variety of fixtures 3 of different specifications and sizes, so as to adapt to the clamping of samples of different sizes, and then the fixture 3 and the sample is placed on the detection platform 1, and the sample is observed by the observer, and the specific position to be observed is selected from the sample after moving the sample. The observer can be a microscope or a scanning electron microscope;

[0078] S2. Place the jig 3 on the cutting machine according to the specific position obtained in S1, and the cutting machine 11 starts to cut the position of the sample on the jig 3 that needs to be observed into a specified small-sized sample. The specified required size is generally no more than 2cm× in length and width...

Embodiment 2

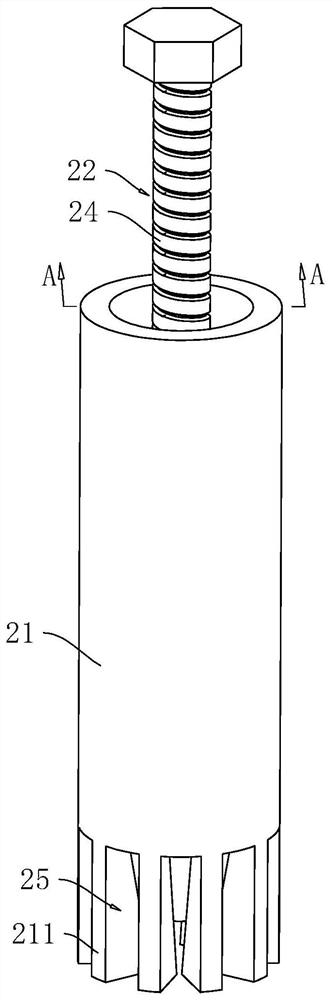

[0111] refer to Figure 8 , The difference between this embodiment and Embodiment 1 is that the fixing assembly 22 includes an electromagnet 28 and a control switch 29, and there are four electromagnets 28 fixedly installed on the lower surfaces of the four connecting seats 311, and the electromagnets 28 Located between the socket pipe 21 and the base 31, the lower surface of the electromagnet 28 is flush with the lower surface of the base 31, and the electromagnet 28 is adsorbed on the detection table 1 after being energized; the control switch 29 is fixedly installed on the side wall of the base 31, and The control switch 29 is electrically connected with the four electromagnets 28 , and the control switch 29 controls the power on and off of the four electromagnets 28 .

[0112] The working principle of the embodiment of the present application is:

[0113] The control switch 29 is activated so that the four electromagnets 28 are energized, and the four electromagnets 28 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com