Modified particle loaded fiber diaphragm for thermal battery and preparation method of modified particle loaded fiber diaphragm

A thermal battery and modification technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as low loading efficiency and small loading of modified particles, and achieve diffusion and uniform distribution. The method is simple and widely used The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

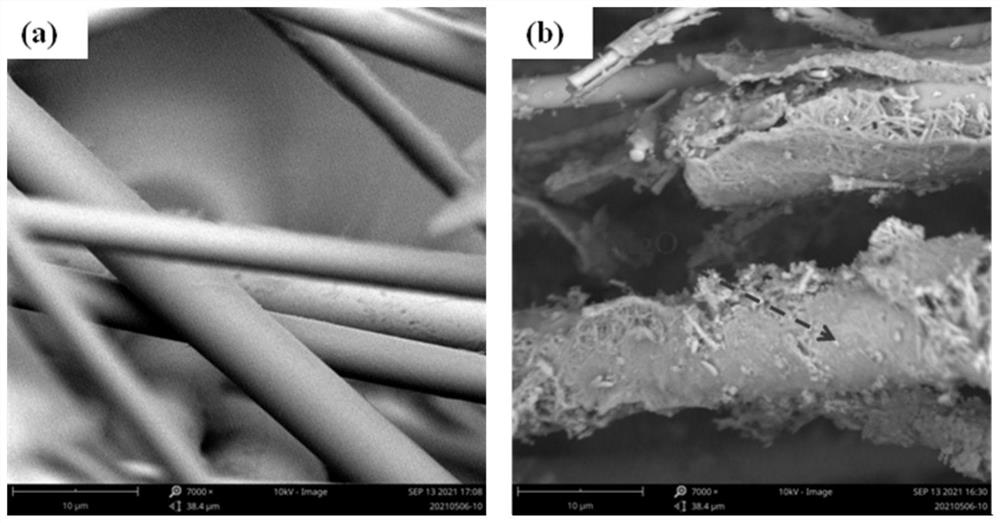

Image

Examples

Embodiment 1

[0023] This embodiment provides a method of loading MGO modified particles for a thermal cell BN fiber membrane, and specifically includes the following steps:

[0024] (1) Weigh 0.65G mg (NO 3 ) 2 · 6h 2 O, and transfer to the surface of the thermal cell;

[0025] (2) Low melting point metal salt Mg will carry 3 ) 2 · 6h 2 The thermal cell of O transfer from the BN fiber diaphragm to the oven at 100 ° C under the protection of nitrogen, so that low melting metal salt Mg (NO 3 ) 2 · 6h 2 O Uniformly distributed in the BN fiber diaphragm of the thermal cell to make a load of alkali Mg (NO 3 ) 2 BN fiber diaphragm for thermal cells;

[0026] (3) Load a basic mg (NO 3 ) 2 The thermal cell is transferred to the muffle furnace in the muffle furnace, calcined at 450 ° C for 2 h, so that the base mg (NO 3 ) 2 Decompose at 450 ° C, and MgO modified particles were generated in a BN fiber diaphragm in a thermal cell to prepare a BN fiber diaphragm for a thermal cell loaded with MgO modified...

Embodiment 2

[0028] This embodiment provides a BN fiber diaphragm load Al for a thermal cell 2 O 3 Modified particle preparation method, specifically includes the following steps:

[0029] (1) Weigh 0.74G Al (NO 3 ) 3 · 9h 2 O, and transfer to the surface of the thermal cell;

[0030] (2) Low melting point metal salt Al (NO) 3 ) 3 · 9h 2 The thermal cell of O was transferred to the oven under an oven under an oven at 100 ° C insulation treatment for 2 h, so that the low melting point metal salt Al (NO 3 ) 3 · 9h 2 O Uniformly distributed in the BN fiber diaphragm of the thermal cell to make a load Al (NO 3 ) 3 BN fiber diaphragm for thermal cells;

[0031] (3) A load is Al (NO 3 ) 3 The thermal cell is transferred to the muffle furnace with a BN fiber membrane, calcined at 200 ° C for 2 h, so that Al (NO 3 ) 3 Decompose at 200 ° C, and generate Al in the primary bn fiber diaphragm in the thermal cell 2 O 3 Modified particles, make loads with Al 2 O 3 BN fiber diaphragm of modified particles. T...

Embodiment 3

[0033] This embodiment provides a thermal battery mullite (Al 2 O 3 And complexes and SIO 2 And the mixture of the complex) Fiber diaphragm load MgO modified particles, including the steps of:

[0034] (1) Weigh 0.32G mg (NO 3 ) 2 · 6h 2 O, and transfer to the heat battery of φ32mm mullite fiber diaphragm diaphragm;

[0035] (2) Low melting point metal salt Mg will carry 3 ) 2 · 6h 2 The thermal cell of O was transferred to a mixed gas of nitrogen and argon in a mixed gas treatment for 3 h under a mixed gas of nitrogen and argon, so that low melting point metal salt Mg (NO 3 ) 2 · 6h 2 O Uniformly distributed in the Mohuoite fiber diaphragm in the thermal cell to make a load of alkali Mg (NO 3 ) 2 Thermal cell with mullite fiber diaphragm;

[0036] (3) Load a basic mg (NO 3 ) 2 The thermal cell is transferred to the muffle furnace with a mullite furnace, calcined at 450 ° C for 2 h, so that the base mg (NO 3 ) 2 Decompose at 450 ° C, and MgO modified particles were generated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com