Preparation method of citrus lactobacillus capsule with high flavone utilization degree

A technology of lactic acid bacteria and availability, applied in the field of preparation of citrus lactic acid bacteria capsules, can solve the problems of high cold chain transportation cost, complex extraction process, low environmental friendliness, etc., and achieves improving biotransformation efficiency, promoting effective play, and improving probiotic bacteria. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

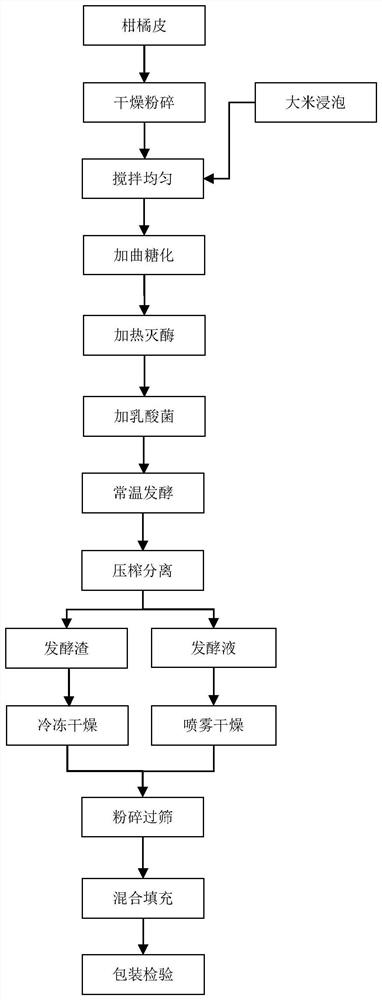

Method used

Image

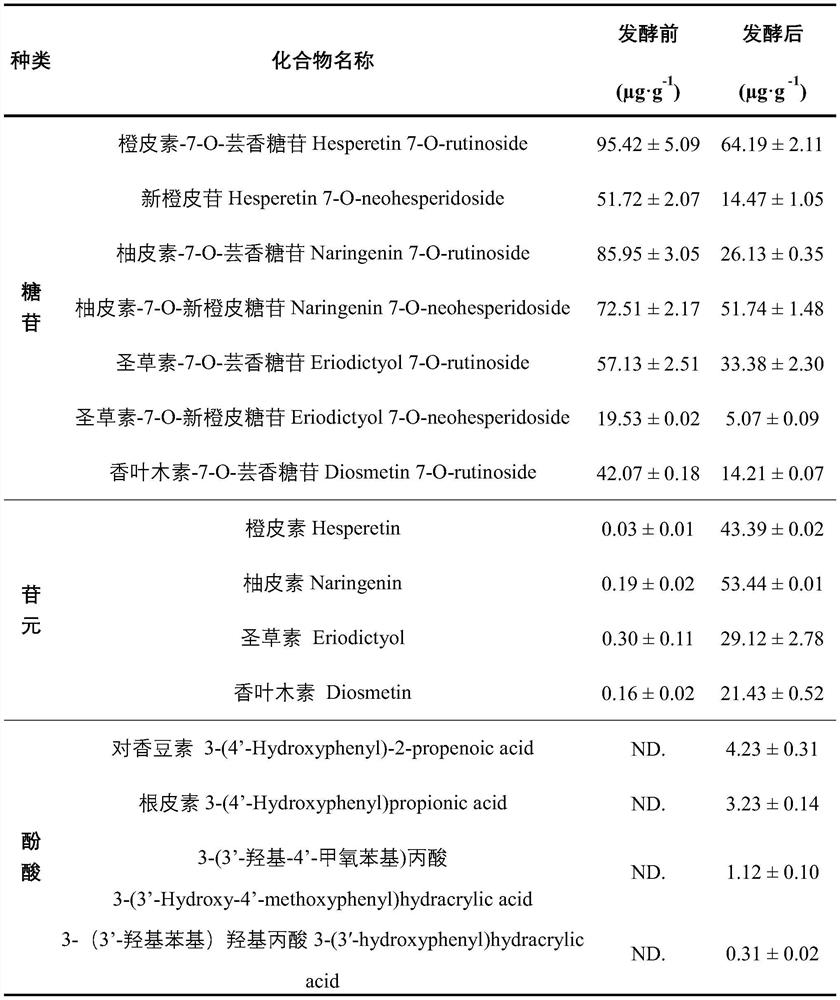

Examples

Embodiment 1

[0029] Weigh 1000g of fresh citrus peel, put it in a constant temperature blast drying oven, dry it with hot air at 70°C for 4 hours, measure the moisture content to 8.4%, roll it with a roller mill and pass it through a 60-mesh sieve to obtain 300g of citrus peel powder, and set aside.

[0030] Weigh 100g of rice, wash and add 100g of water to soak overnight, mix well with citrus peel powder, steam in a pot for 15 minutes, cool to below 40°C, add 10g of sweet wine koji while it is hot, mix well, and place in a 35°C water bath to keep warm and saccharify .

[0031] After 8-12 hours of saccharification, heat to 70°C to sterilize enzymes for 5 minutes, cool to room temperature (20±5°C), add 50 g of L.acidophilus LA85 culture solution that has been activated in MRS liquid medium, and measure its The number of viable bacteria reached 6.2logCFU / g.

[0032] Under the condition of a constant temperature of 30°C, it was covered and left to ferment for 5 days, wrapped with 100-mesh ga...

Embodiment 2

[0037] Weigh 1000g of fresh citrus peel, put it in a constant temperature blast drying oven, dry it with hot air at 65°C for 6 hours, measure the moisture content to 7.6%, roll it with a roller mill and pass it through a 60-mesh sieve to obtain 315g of citrus peel powder, which is set aside.

[0038] Weigh 95g of rice, wash and add 95g of water to soak overnight, mix well with citrus peel powder, steam in a pot for 15 minutes, cool to below 40°C, add 10.1g of sweet wine koji while it is hot, mix well, and keep in a 35°C water bath saccharification.

[0039] After 8-12 hours of saccharification, heat to 70°C to sterilize enzymes for 5 minutes, cool to room temperature (20±5°C), add 50 g of culture solution of Lactobacillus plantarum N13 that has been activated in MRS liquid medium, and measure its activity. The bacterial count reached 5.1log CFU / g.

[0040] Under the condition of a constant temperature of 35°C, it was covered and left to ferment for 7 days, wrapped with 100-me...

Embodiment 3

[0045] 10kg of dried citrus peels and 10kg of dried citrus young fruit slices were crushed with a roller mill and passed through a 60-mesh sieve to obtain 19kg of citrus peel powder, and a small amount of reserved samples were sealed and frozen (-18°C) for storage until testing .

[0046]Weigh 3kg of rice, wash and add 3kg of water to soak overnight, mix well with citrus peel powder, steam in a pot for 30 minutes, cool to below 40°C, add 0.5kg of sweet wine koji while it is hot, mix well, and place in a 35°C interlayer tank Insulated saccharification.

[0047] After 18-24 hours of saccharification, heat to 70°C to sterilize the enzyme for 10 minutes, then cool to 35°C and add 0.5 kg of MRS liquid medium activation solution of Lactobacillus brevis L.

[0048] Under the condition of a constant temperature of 32-35°C, cover and stand for fermentation for 3-7 days, separate with a screw press, collect 20.5 kg of fermentation residue and 10.2 kg of fermentation liquid, and set asi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com