Method for solidifying calcium arsenate slag cement

A technology of cement solidification and calcium arsenate, applied in chemical instruments and methods, solid waste removal, solid waste management, etc., can solve the problem of high transportation and landfill costs, large weight gain ratio and volume increase ratio, and economic pressure on treatment Large and other problems, to achieve the effect of low treatment cost, long-term stable improvement, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

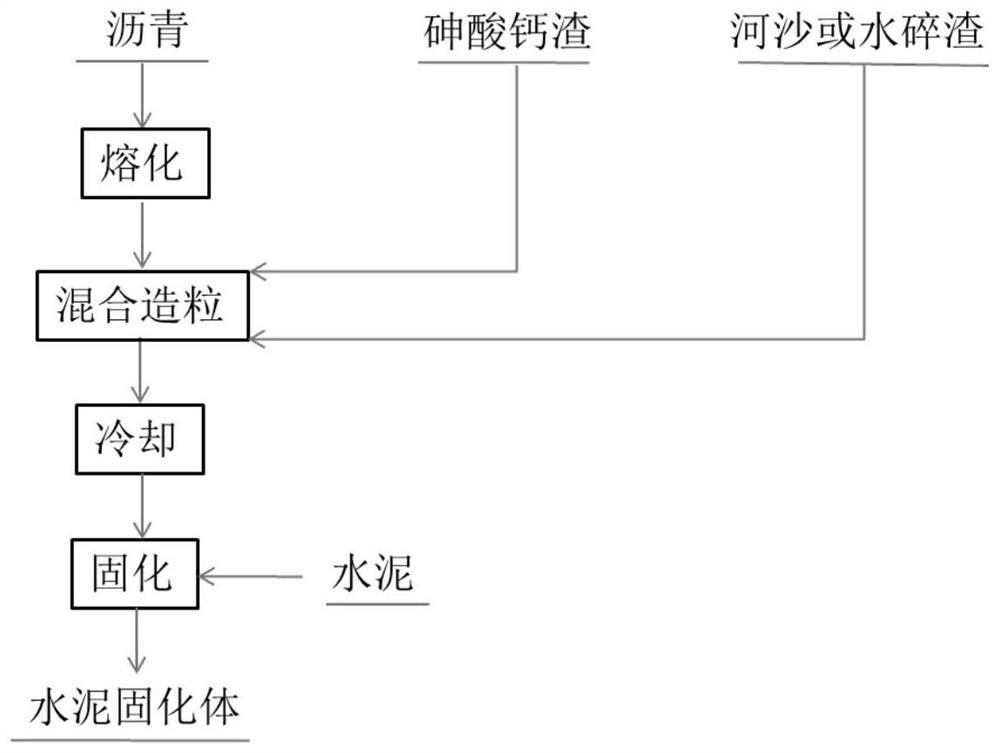

Method used

Image

Examples

Embodiment 1

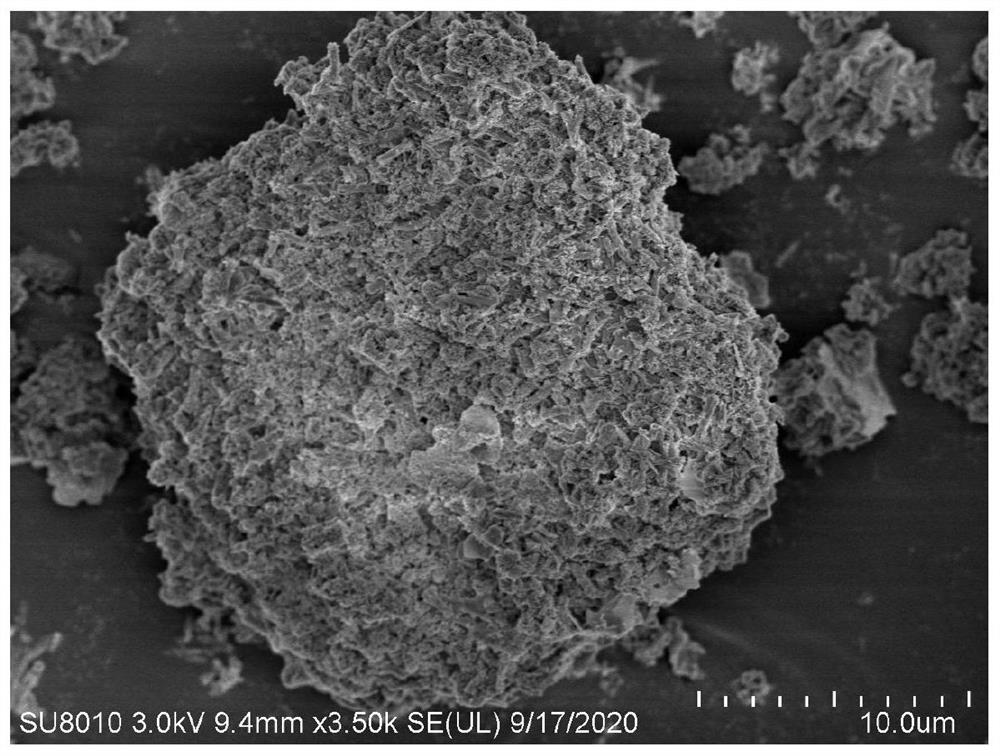

[0031] Take 30g of calcium arsenate slag and 30g of asphalt, control the temperature at 150°C, mix, stir and cool to make granules (particle size 0.5-3mm). Take 6g of 425# cement, mix it with calcium arsenate particles, stir evenly, and let it stand for 28 days. According to the national standard (HJ / T299-2007), the leaching concentration of arsenic was detected, the leaching concentration of arsenic was 0.208mg / L, and the strength test result was 17.8MPa, which met the discharge standard stipulated by the state.

Embodiment 2

[0033] Take 30g of calcium arsenate slag and 30g of asphalt, control the temperature at 150°C, mix, stir and cool to make granules (particle size 0.5-3mm). Take 30 grams of river sand, 60 grams of 425# cement, mix them with calcium arsenate particles, stir evenly, and let it stand for 28 days. According to the national standard (HJ / T299-2007), the leaching concentration of arsenic was tested, the leaching concentration of arsenic was 0.011mg / L, and the strength test result was 50.1MPa, which met the discharge standard stipulated by the state.

Embodiment 3

[0035] Take 30g of calcium arsenate slag and 3g of asphalt, control the temperature at 150°C, mix, stir and cool to make granules (particle size 0.5-3mm). Take 6g of 425# cement, mix it with calcium arsenate particles, stir evenly, and let it stand for 28 days. According to the national standard (HJ / T299-2007), the leaching concentration of arsenic was tested. The leaching concentration of arsenic was 0.627mg / L, and the strength test result was 13.7MPa, which reached the national emission standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com