Label film and preparation method thereof

A label and polyethylene technology, applied in the coating and other directions, can solve the problems of single component of the label film and poor surface printing performance of the product, and achieve the effect of not easy to break and aging, preventing aging and yellowing, and reducing the precipitation of crystal points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

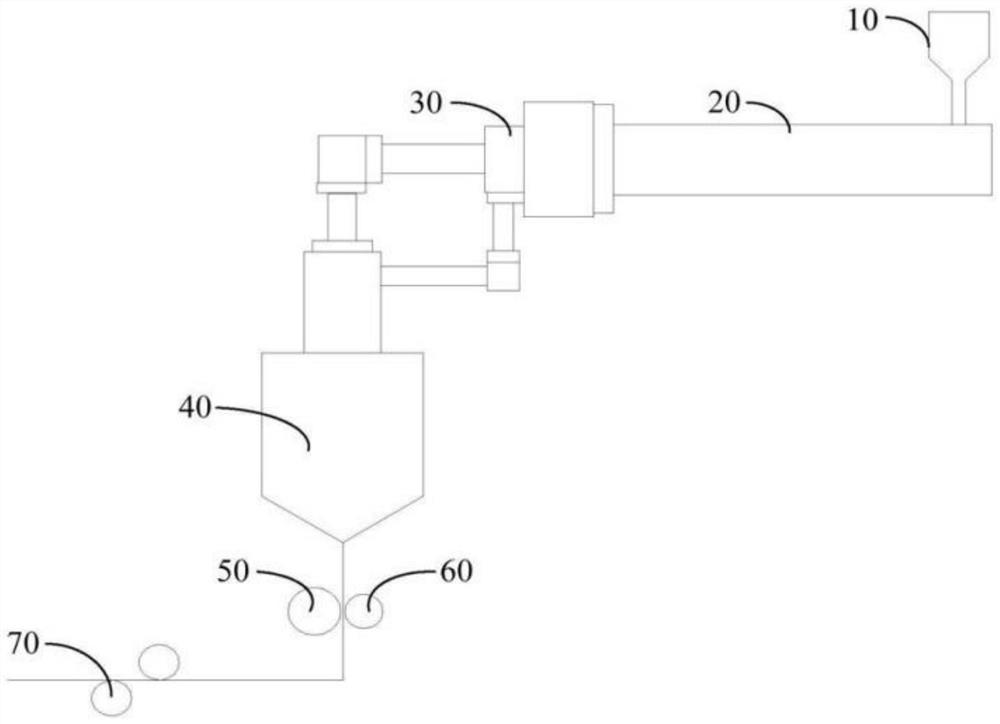

Image

Examples

Embodiment 1

[0040] A label film comprising the following raw materials in parts by weight:

[0041] 40 parts of polyethylene, 30 parts of polymethacrylate, 12 parts of acrylate, 5 parts of masterbatch, 1 part of antioxidant, 0.7 part of leveling agent, 1.0 part of wetting and dispersing agent.

[0042] Specifically, the leveling agent is an acrylic leveling agent.

[0043] The wetting and dispersing agent is HLD-5 wetting and dispersing agent.

[0044] Polyethylene includes raw materials with the following mass fractions:

[0045] Low-density polyethylene 25%, high-density polyethylene 45% and modified polyethylene 30%.

[0046] The modified polyethylene is a mixture of ethylene-acrylate copolymer and ethylene-methacrylate copolymer in any proportion.

[0047] The antioxidant is 1010 antioxidant.

[0048] A method for preparing a label film, comprising the steps of:

[0049] (1) Take the above-mentioned raw materials in proportion, and set aside;

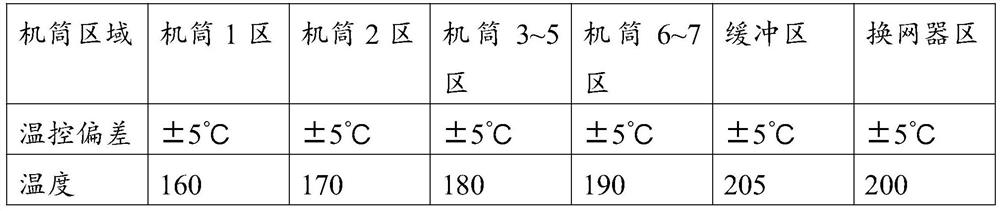

[0050] (2) Uniformly mix polyethyl...

Embodiment 2

[0063] A label film comprising the following raw materials in parts by weight:

[0064] 35 parts of polyethylene, 25 parts of polymethacrylate, 10 parts of acrylate, 10 parts of masterbatch, 1 part of antioxidant, 1 part of leveling agent, 0.6 part of wetting and dispersing agent.

[0065] Specifically, the leveling agent is a silicone leveling agent.

[0066] Wetting and dispersing additives are solvent-based wetting and dispersing additives.

[0067] Polyethylene includes raw materials with the following mass fractions:

[0068] Low-density polyethylene 20%, high-density polyethylene 45% and modified polyethylene 35%.

[0069] The modified polyethylene is ethylene-acrylate copolymer, ethylene-methacrylate copolymer, ethylene-butylene acrylate copolymer, maleic anhydride grafted polyethylene and chlorinated polyethylene mixed in any proportion.

[0070] The antioxidant is 1076 antioxidant.

[0071] A method for preparing a label film, comprising the steps of:

[0072] (1...

Embodiment 3

[0087] A label film comprising the following raw materials in parts by weight:

[0088] 45 parts of polyethylene, 35 parts of polymethacrylate, 15 parts of acrylate, 13 parts of masterbatch, 2.5 parts of antioxidant, 0.8 part of leveling agent, 1.3 parts of wetting and dispersing agent.

[0089] Specifically, the leveling agent is a phosphoric acid ester modified acrylic leveling agent.

[0090] The wetting and dispersing agent is HLD-5 wetting and dispersing agent.

[0091] Polyethylene includes raw materials with the following mass fractions:

[0092] Low-density polyethylene 30%, high-density polyethylene 35% and modified polyethylene 35%.

[0093] The modified polyethylene is a mixture of ethylene-butylene acrylate copolymer, maleic anhydride grafted polyethylene and chlorinated polyethylene in any proportion.

[0094] The antioxidant is 1010 antioxidant.

[0095] A method for preparing a label film, comprising the steps of:

[0096] (1) Take the above-mentioned raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com