Sintered NdFeB magnet surface corrosion-resistant composite coating and preparation method thereof

A composite coating and corrosion-resistant technology, which is applied in coatings, anti-corrosion coatings, magnetic objects, etc., can solve the problems of limited improvement in the corrosion resistance of magnets, achieve uniform and controllable coating thickness, extend service life, and improve The effect of coating corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a corrosion-resistant composite coating on the surface of a sintered NdFeB magnet, comprising the following steps:

[0029] (1) Preparation of Co-BDC nanosheets;

[0030] 32ml of N,N-dimethylformamide was added to 2ml of ethanol and 2ml of water, mixed to form solution A, 125.9mg of terephthalic acid was dissolved in solution A to form solution B, and 180.2mg of cobalt chloride hexahydrate was dissolved. In solution B, to form solution C, 0.8 ml of triethylamine was rapidly added to solution C, magnetically stirred for 5 min, and then the solution C was continuously sonicated for 8 h, and the product was centrifuged, washed with ethanol, and dried in an oven. Dry to obtain Co-BDC nanosheets;

[0031] (2) Pretreatment of sintered NdFeB magnets;

[0032] First, the sintered NdFeB magnets were pickled in 3 wt% nitric acid solution for 20 s; then, the magnets were sonicated in deionized water and ethanol in sequence for 60 s, and finally, the magne...

Embodiment 2

[0048] The preparation method of this example is the same as that of Example 1, except that the dispersion concentration of Co-BDC nanosheets in the composite coating is 25 g / L.

[0049] After soaking the sintered NdFeB magnet with the composite coating on the surface prepared in Example 2 in 3.5wt% NaCl solution for 5 days, the corrosion-resistant composite coating on the surface of the sintered NdFeB magnet was obtained according to the above steps. Impedance (|Z|0.01Hz) is 1.19×10 8 Ω cm -2 , which was four orders of magnitude higher than that of control group 1. After immersion for 30 days, the electrochemical polarization curve test shows that the corrosion potential is -0.382V, and the self-corrosion current density is 7.639×10 -9 A cm -2 , which was four orders of magnitude lower than that of control group 1.

Embodiment 3

[0051] The preparation method of this example is the same as that of Example 1, except that the dispersion concentration of Co-BDC nanosheets in the composite coating is 75 g / L.

[0052] After soaking the sintered NdFeB magnet with the composite coating on the surface prepared in Example 3 in 3.5wt% NaCl solution for 5 days, the corrosion-resistant composite coating on the surface of the sintered NdFeB magnet was obtained according to the above steps. Impedance (|Z|0.01Hz) is 8.92×10 7 Ω cm -2 , which was three orders of magnitude higher than that of control group 1. After soaking for 30 days, the electrochemical polarization curve test shows that the corrosion potential is -0.677V, and the self-corrosion current density is 8.772×10 -7 A cm -2 , which was two orders of magnitude lower than that of control group 1.

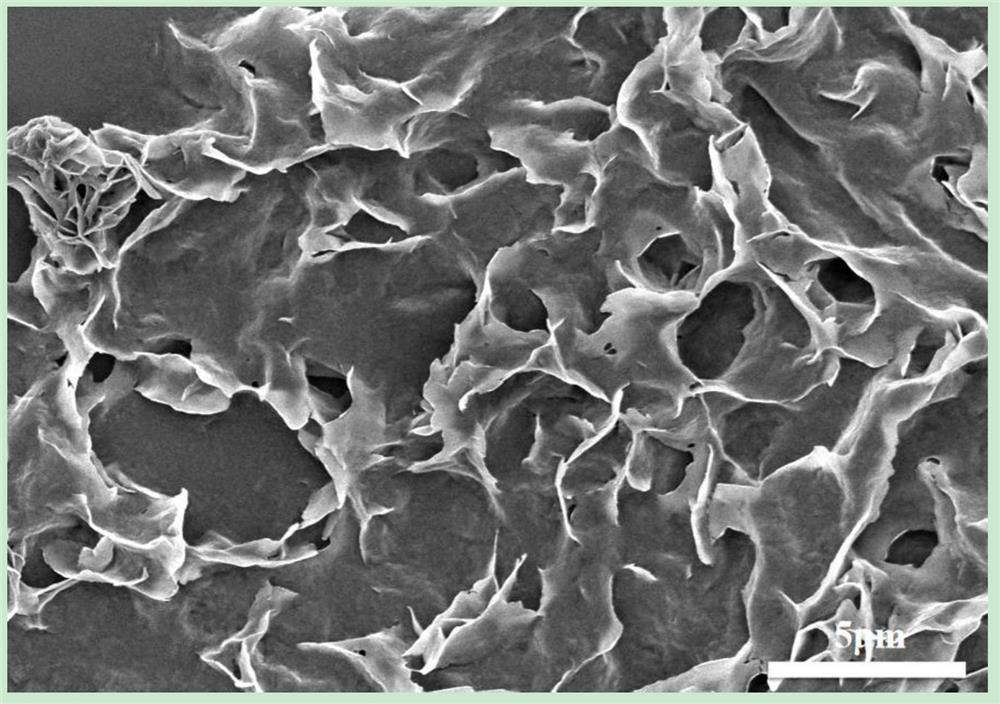

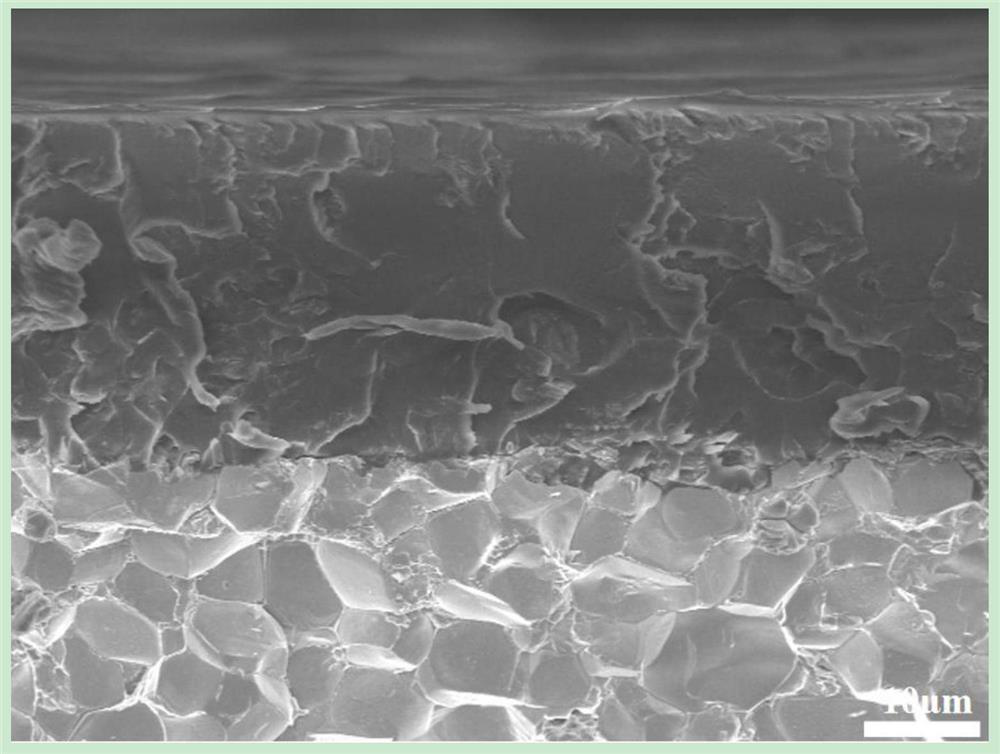

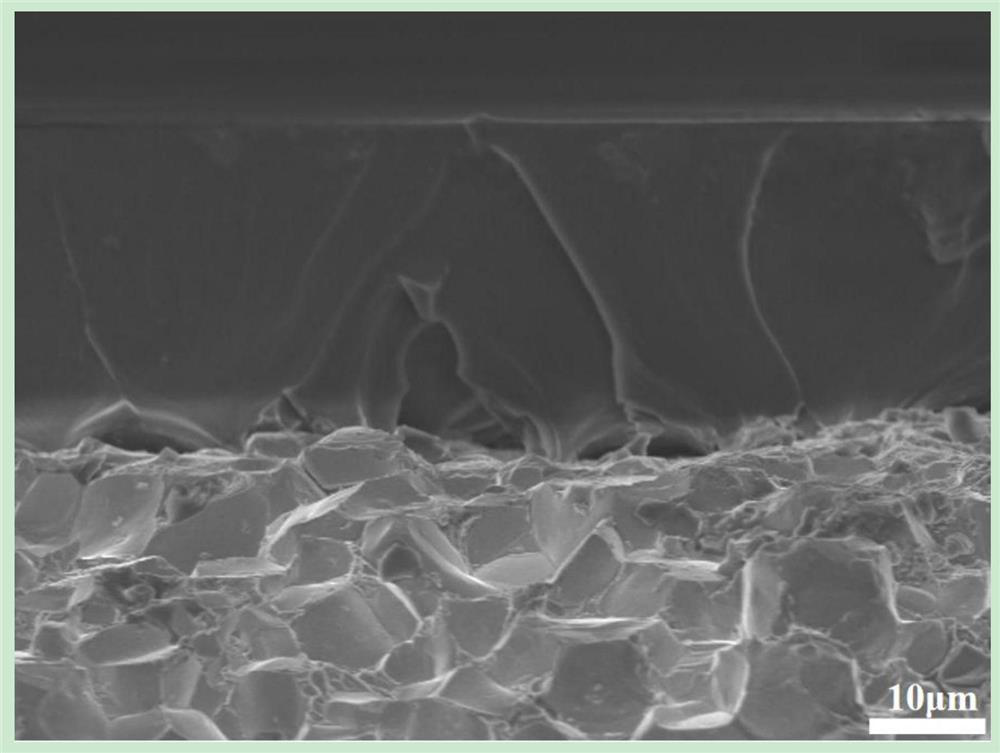

[0053] figure 1 This is a FESEM photo of the Co-BDC nanosheet in the present invention. The thickness of the nanosheet is relatively thin, the surface is rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com