Rare earth alloyed steel, nitriding method thereof and nitrided steel part

A technology of rare earth alloy and nitriding steel, which is applied in the coating process of metal materials, coating, and gas emission reduction, and can solve the problems of equipment pollution, corrosion, and limited penetration depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

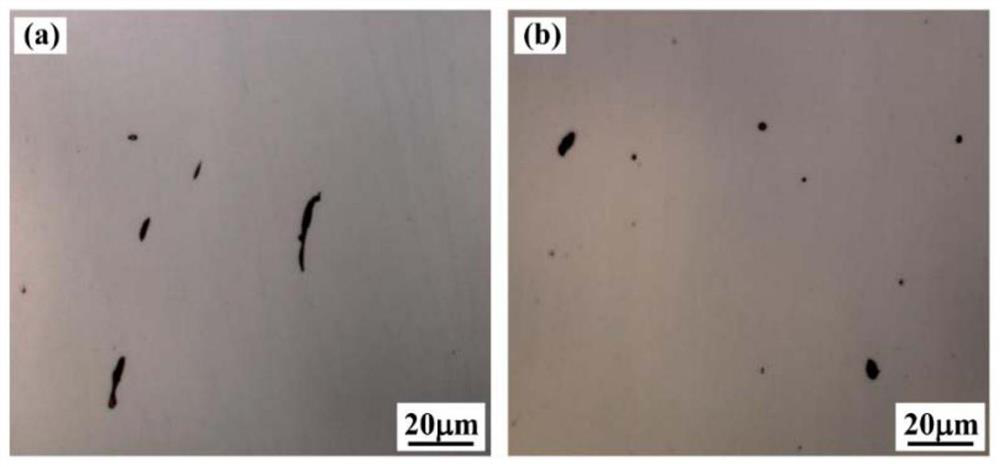

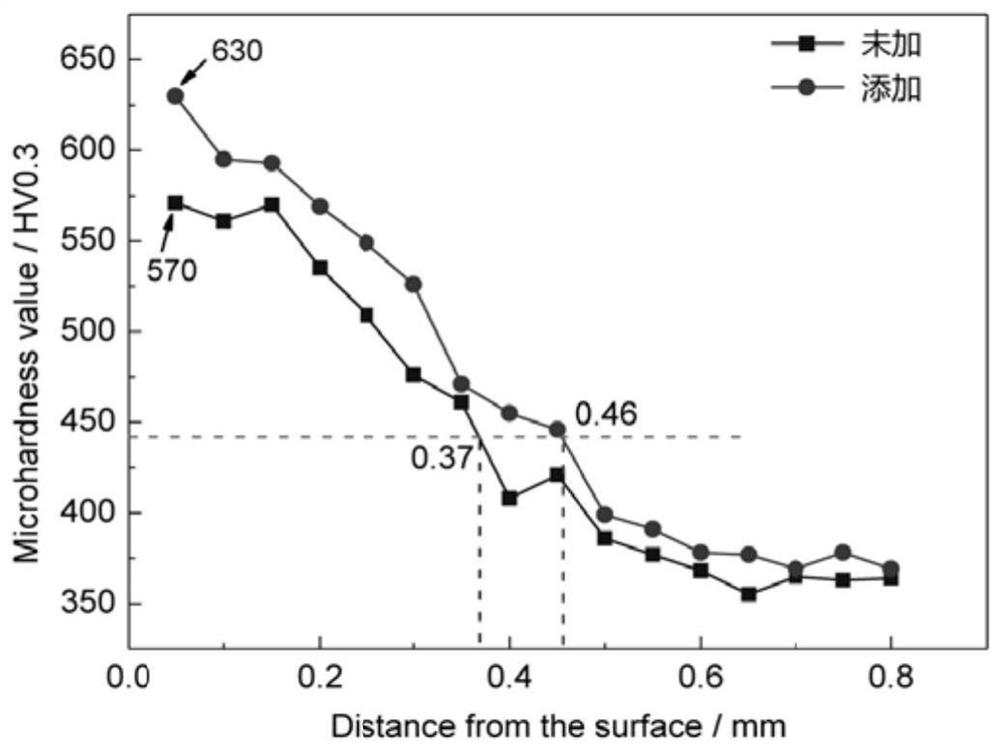

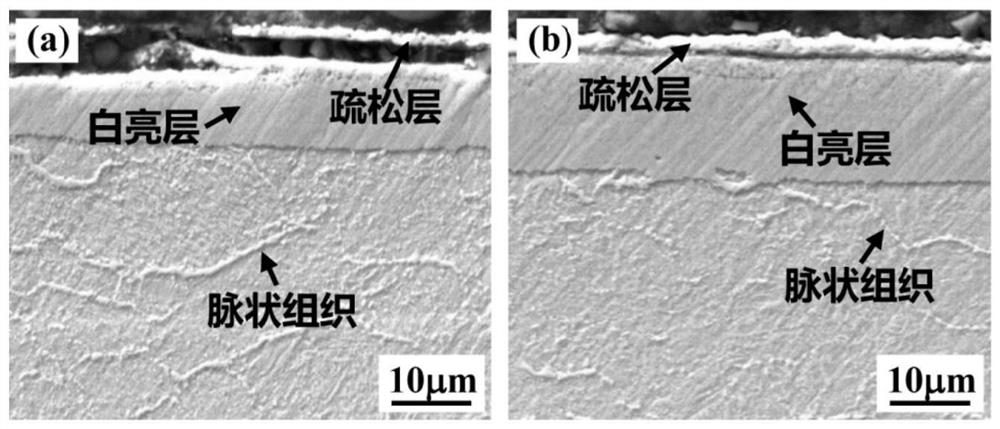

[0034] Rare earth alloyed steel smelting 42CrMo to as matrix material, the chemical components and their contents are: C was 0.37wt%, Si is 0.15wt%, Mn was 0.65wt%, Cr was 0.85wt%, Mo is 0.15wt%, Ni was 0.25wt%, P was 0.025wt%, S of 0.015 wt% rare earth alloy is added in the smelting process, in which the mass percentage of the rare earth alloy is wt: 0.01%, balance iron and impurities . The rare earth alloy comprising a mass fraction of 50% Ce, 29% of La, 5% and 16% of Pr Nd. The rare earth alloy of the surface of the iron atoms in the steel making energy prices, increasing the driving force to capture the N atom, so that the diffusion coefficient increases, the diffusion rate up, nitridation process period is shortened; while the steel material in the smelting process since rare earth alloy was added, the activity of high rare earth element is added, may be mixed with an Al 2 O 3 The reaction MnS sulfides and achieve deoxidizing steel desulfurization, such as figure 1 As shown i...

Embodiment 2

[0045] A rare earth alloying steel, a smelting of 42 Crmo as a matrix, including 0.33 wt% C, 0.17 wt% Si, 0.72 wt% Mn, 0.95 wt% of Cr, 0.19 wt% MO, 0.23 wt% Ni, 0.022 wt% of P, 0.018 wt% of S, 0.022 wt% of the rare earth alloy, the balance iron and impurities. The rare earth alloy comprises a mass fraction of 50% CE, 29% La, 5% Pr and 16% Nd.

[0046] The following righteous alloying steel is carried out using the following steps:

[0047] S1: Forging. The above-mentioned rare earth alloyed steel was heated to 1080 ° C, and 3500 tons of electric hammers forged, and the three-dimensional, molded, punching and other steps can be forged as the various types of parts required for the required model;

[0048] S2: orthogonal. The part blank of the completion step S1 was heated to 660 ° C, heat insulation for 4 h, cooled to 200 ° C, cooled, cooled in air;

[0049] S3: Roughing. Rough processing of the blank in step S2, including the outer circle and end faces or the like;

[0050] S4: Tr...

Embodiment 3

[0055] A rare earth alloying steel, smelting with 42 Crmo as a matrix, including 0.35 wt% C, 0.25 wt% Si, 0.84 wt% Mn, 1.05 wt% Cr, 0.22 wt% MO, 0.2% by weight Ni, 0.023 wt% of P, 0.019 wt% of S, 0.03 wt% of rare earth alloy, the balance iron and impurities. The rare earth alloy comprises a mass fraction of 50% CE, 29% La, 5% Pr and 16% Nd.

[0056] The following righteous alloying steel is carried out using the following steps:

[0057] S1: Forging. The above-mentioned rare earth alloyed steel was heated to 1150 ° C, and the three-ton, molded, punching, etc., after the three-tenthohydrotic, molded, punching, etc., can be forged as the various types of parts required for the required model;

[0058] S2: orthogonal. The part blank of the completion step S1 was heated to 710 ° C, heat insulation for 4 h, cooled to 200 ° C, baked, cooled in air;

[0059] S3: Roughing. Rough processing of the blank in step S2, including the outer circle and end faces or the like;

[0060] S4: Treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com