Low-nitrogen ultrahigh-strength hot rolled steel strip with thickness of 4-10 mm and production method thereof

A production method and ultra-high-strength technology, applied in the field of steel strip rolling, can solve the problems of poor process adaptability, high alloy cost and process cost, etc., and achieve the effects of good strength and toughness matching, promotion of development and promotion, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The chemical composition is calculated by weight percentage (%): C 0.12, Si 0.29, Mn 1.90, P 0.009, S 0.002, Als 0.023, N 0.0028, Cr 0.22, Ti 0.17, V 0.09, Mo 0.17, through smelting and low temperature constant speed Casting, 230mm thick steel slab was obtained after putting into 5mm light reduction, the slab heating temperature was 1273°C, the rough rolling cumulative compression ratio was 4.3, the rough rolling exit temperature was 1045°C, the thickness of the intermediate slab after rough rolling was 54mm, and the finishing rolling cumulative compression ratio was 9 , the finish rolling entrance temperature is 1003°C, the finish rolling finish temperature is 861°C, the steel plate thickness after finish rolling is 6mm, the laminar cooling rate is 41°C / s, and the finish cooling temperature is 573°C.

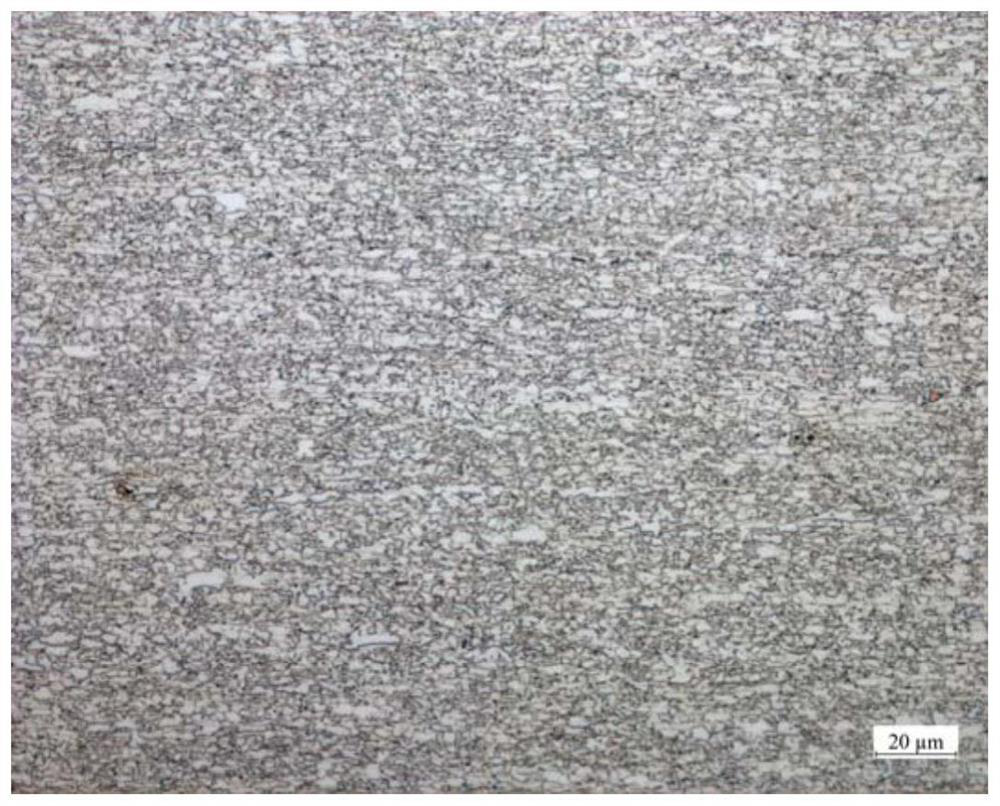

[0047] The yield strength of the finished steel is 897MPa, the tensile strength is 973MPa, the elongation is 18.5%, the 180° cold bending d=2a is qualified, the microstru...

Embodiment 2

[0049] The chemical composition is calculated by weight percentage (%): C 0.14, Si 0.25, Mn 1.85, P 0.011, S 0.003, Als 0.035, N 0.0024, Nb 0.039, Ti 0.17, V 0.08, Mo 0.16, through smelting and low temperature constant speed Casting, 200mm thick steel slab was obtained after putting into 5mm light reduction, the slab heating temperature was 1259°C, the rough rolling cumulative compression ratio was 4.3, the rough rolling exit temperature was 1100°C, the thickness of the intermediate slab after rough rolling was 47mm, and the finishing rolling cumulative compression ratio was 5.9 , the finish rolling entrance temperature is 1020°C, the finish rolling finish temperature is 900°C, the steel plate thickness after finish rolling is 8mm, the laminar cooling rate is 36°C / s, and the finish cooling temperature is 619°C.

[0050] The yield strength of the finished steel is 945MPa, the tensile strength is 1006MPa, the elongation is 19%, the 180° cold bending d=2a is qualified, the microst...

Embodiment 3

[0052] The chemical composition is calculated by weight percentage (%): C 0.16, Si 0.27, Mn 1.95, P 0.010, S 0.004, Als 0.041, N 0.0018, V 0.10, Ti 0.17, Ni 0.22, Mo 0.15, through smelting and low temperature constant speed Casting, 250mm thick steel slab was obtained after putting into 5mm light reduction, the slab heating temperature was 1268°C, the rough rolling cumulative compression ratio was 5, the rough rolling exit temperature was 1091°C, the thickness of the intermediate billet after rough rolling was 50mm, the finishing rolling cumulative compression ratio was 6.3, the finishing rolling The rolling entrance temperature is 1011°C, the finishing rolling temperature is 930°C, the steel plate thickness after finishing rolling is 8mm, the laminar cooling rate is 50°C / s, and the finishing cooling temperature is 603°C.

[0053] The yield strength of the finished steel is 961MPa, the tensile strength is 1032MPa, the elongation is 17%, the 180° cold bending d=2a is qualified, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com