Polystyrene seed emulsion and preparation method thereof

A technology of polystyrene and seeds, applied in the field of polystyrene seed emulsion and its preparation, to achieve the effects of easy availability of raw materials, high conversion rate of monomers, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Materials: commercially available styrene monomer, Fluka's reagent grade potassium persulfate initiator, industrial grade BASF SLS103 (sodium dodecyl sulfate) emulsifier (30%), reagent grade Sigma Aldrich's t-DDM (tert-dodecyl sulfate) alkanethiol), reagent grade sodium bicarbonate, SigmaAldrich, distilled water as the polymerization medium.

[0038] First, according to the seed emulsion formula in Table 1, each mixture was prepared for emulsion polymerization. The first step was to replace the oxygen in the reactor with nitrogen, add the advanced mixture and the modified mixture to the reactor, and heat it to 85°C; when the temperature reached 85°C At 0C, the starter mix and monomer mixture were added simultaneously, polymerization began, the temperature would rise to 90C for about 5 minutes, and the reactor was immediately cooled to 80C and held for 5 hours.

[0039] Table 1 Recipe of seed emulsion

[0040]

[0041]

Embodiment 2

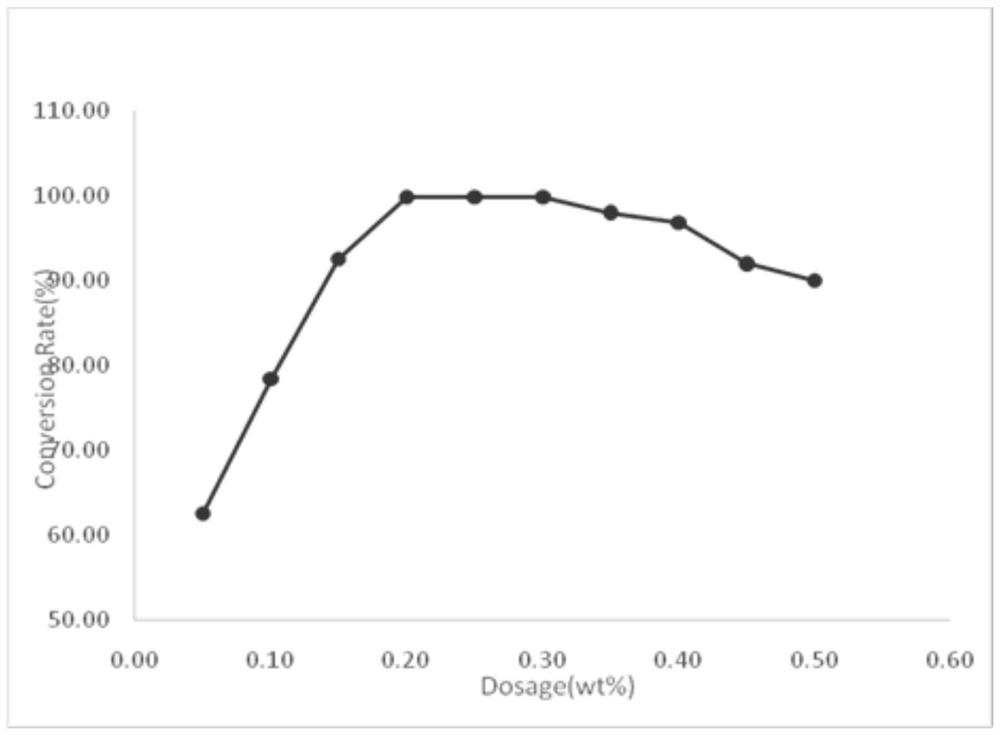

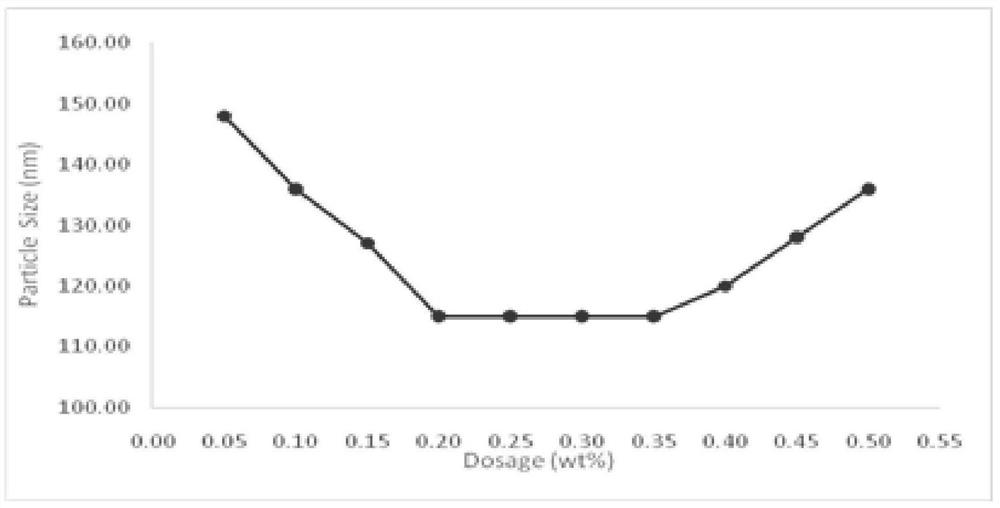

[0043] The preparation method is the same as that in Example 1. The polymerization is based on the seed latex formulation in Table 1. The dosage of the initiator potassium persulfate is 0.10%, 0.15%, 0.20%, 0.25%, 0.30%, 0.35%, 0.40%, 0.45% and 0.50% respectively. The weight percentage of the monomer was added, the amount of potassium persulfate of the initiator was changed, and the influence of the monomer conversion rate and particle size of the initiator was observed. The solid content of latex at 105°C was determined by gravimetric method, and the conversion rate of monomer was calculated. The test results are as follows figure 1 shown. Use a particle size analyzer (Melvin particle size analyzer) to analyze the particle size, dilute the latex emulsion with a certain amount of water to obtain the concentration to be tested, and the test results are as follows figure 2 shown.

[0044] In other embodiments, ammonium persulfate and sodium persulfate can also be used as init...

Embodiment 3

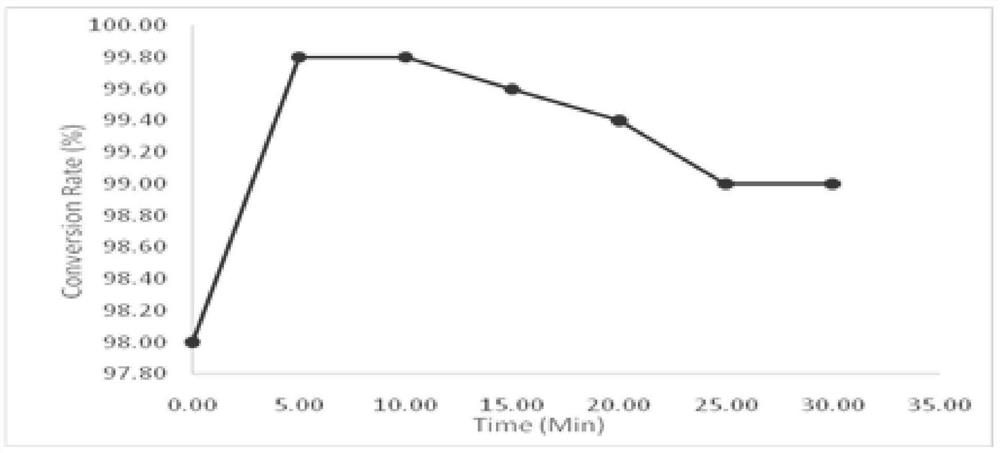

[0048] The preparation method is the same as in Example 1, and the polymerization is based on the seed latex formula of Table 1, and the consumption of the initiator potassium persulfate is added by 0.20% monomer weight percentage, and the addition of the initiator in the reactor is controlled by the peristaltic metering pump, and the addition time is respectively 0 , 5, 10, 15, 20, 25, 30 minutes. The solid content of latex at 105°C was measured by gravimetric method, and the conversion rate of monomer was calculated. The influence of the addition time of initiator potassium persulfate on the conversion rate of monomer is as follows image 3 shown. Analyze the particle size with a particle size analyzer (Melvin particle size analyzer), dilute the latex emulsion with a certain amount of water to obtain the concentration to be tested, and the effect of the addition time of the initiator potassium persulfate on the particle size is shown in 4.

[0049] image 3Show that the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com