Phosphorus-containing copolyester for toughening flame-retardant polylactic acid and preparation method ofcopolyester

A technology of copolyester and polylactic acid, which is applied in the field of phosphorus-containing copolyester and preparation of toughened flame-retardant polylactic acid, can solve the problems of gap, limited improvement, limited notched impact strength, etc., and achieve improved toughness and good flexibility , the effect of improving the compatibility of the two-phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

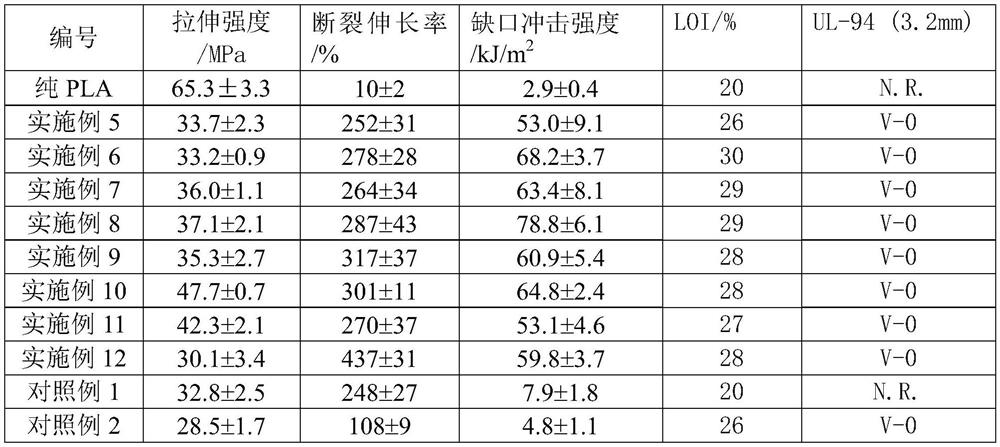

Examples

Embodiment 1

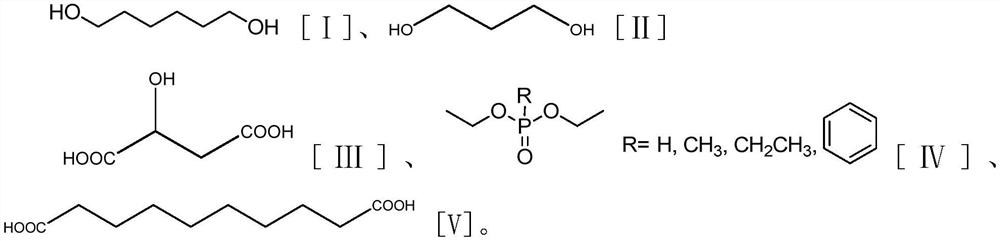

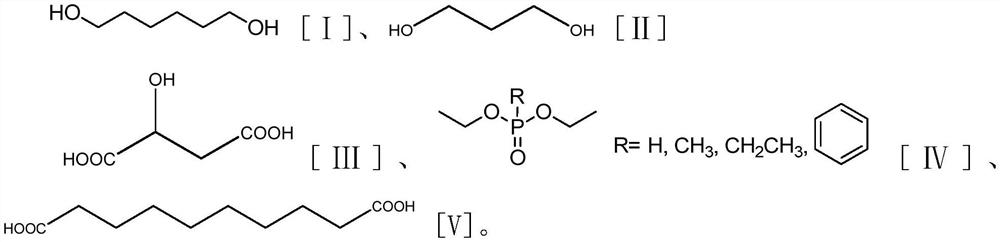

[0027] The phosphorus-containing monomer is diethyl phosphite, the molar ratio of structural units [I] and [II] is 6:4, and the molar ratio of structural units [III], [IV] and [V] is 6:2:2, All the monomers and the catalyst tetrabutyl titanate (0.5%) were fully mixed, stirred and reacted in a nitrogen atmosphere at 170°C for 3 hours, and reacted at 190°C for 3 hours in a vacuum, named CP1.

Embodiment 2

[0029] The phosphorus-containing monomer is dimethyl methyl phosphate, the molar ratio of structural units [I] and [II] is 5:5, and the molar ratio of structural units [III], [IV] and [V] is 4:5:1 , all the monomers and the catalyst zinc acetate (0.3%) were fully mixed, stirred and reacted at 160°C for 5h in a nitrogen atmosphere, and reacted at 190°C for 5h under vacuum, named CP2.

Embodiment 3

[0031] The phosphorus-containing monomer is diethyl ethyl phosphate, the molar ratio of structural units [I] and [II] is 4:6, and the molar ratio of structural units [III], [IV] and [V] is 5:3:2 , mix all the monomers and the catalyst antimony trioxide (0.5%) thoroughly, stir and react in a nitrogen atmosphere at 160°C for 5h, and react at 190°C for 4h under vacuum, named CP3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com