A kind of halogen-free and phosphorus-free low-temperature curing epoxy powder composition with storage stability and preparation method thereof

A storage stability, epoxy powder technology, used in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of low temperature curing, accumulation, environmental and human health hazards, and achieve excellent storage stability, Long shelf life, effect of increasing melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

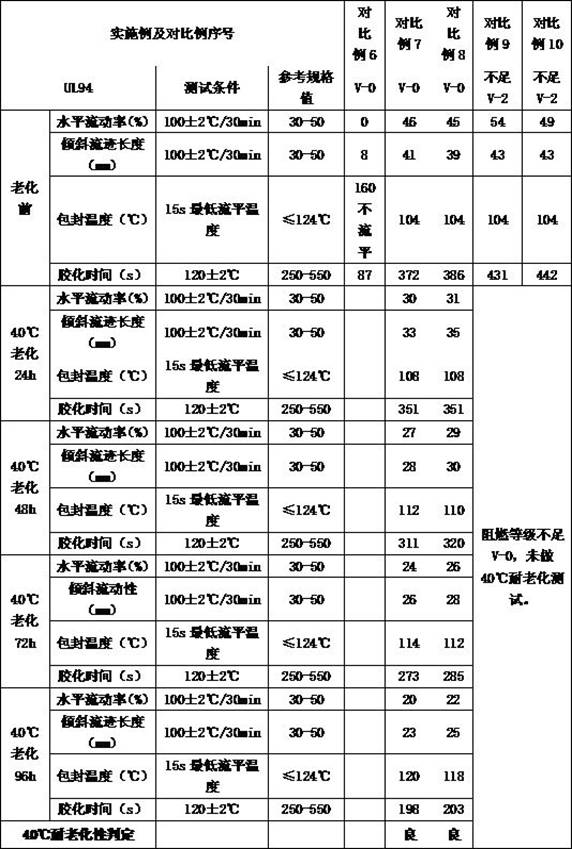

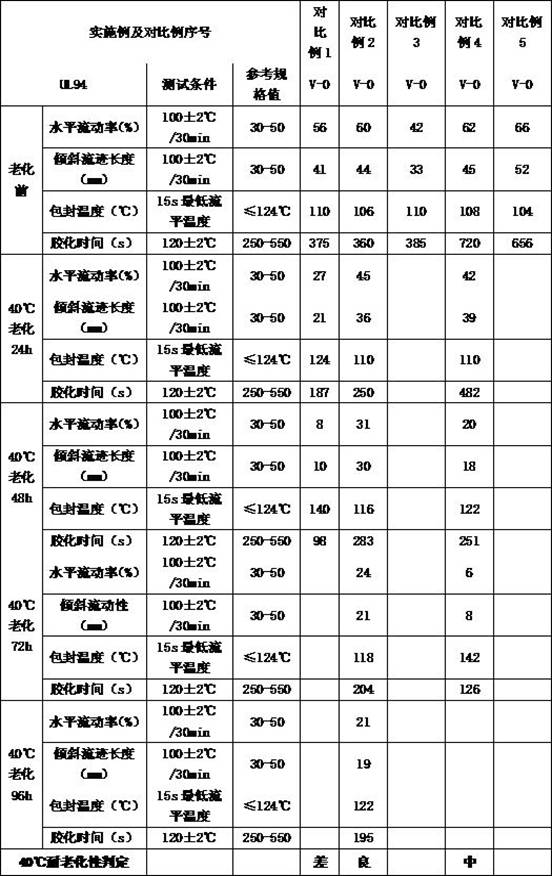

Examples

preparation example Construction

[0083] The preparation method of the halogen-free phosphorus-free low-temperature curing epoxy powder composition with storage stability as described above, the steps are as follows:

[0084] Pre-mix the other raw materials except for the thixotropic agent in a high-speed mixer with a speed of 500-1500rpm, and the mixing time is 5-15 minutes, and then add them to the twin-screw extruder, and set the temperature at 80 -110°C, melt the resin under the shearing state of the screw and mix it evenly with other raw materials. After the melt is cooled by the cooling roller, it enters the ACM mill to be crushed. After wind selection and sieving, the particles with the required particle size are collected. , and finally add an external thixotropic agent to make the powder fluidized and fluffy, that is, a halogen-free and phosphorus-free low-temperature curing epoxy powder composition with storage stability.

[0085] Specifically, the relevant preparation and detection are as follows: ...

Synthetic example 1

[0087] Synthesis Example 1: 1 part of carnauba wax and 3 parts of phenyldimethylurea were mixed evenly with a small high-speed mixer at a rotation speed of 500-1500 rpm, and the mixing time was 5-15 minutes. Then the mixture is melt-extruded with a twin-screw extruder, and the temperature of the extruder is set at 110°C. After being cooled by a cooling roller, it is pulverized with a pulverizer, and passed through a 100-mesh standard sieve to obtain wax powder coated and modified Phenyl dimethyl urea curing agent.

Synthetic example 2

[0088] Synthesis example 2: 1 part of carnauba wax and 3 parts of TDI dimethyl urea were mixed evenly with a small high-speed mixer at a speed of 500-1500 rpm and the mixing time was 5-15 minutes. Then the mixture is melt-extruded with a twin-screw extruder, and the temperature of the extruder is set at 110°C. After being cooled by a cooling roller, it is pulverized with a pulverizer, and passed through a 100-mesh standard sieve to obtain wax powder coated and modified TDI dimethyl urea curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com