Rain-erosion-resistant dust suppressant for building construction as well as preparation method and application of rain-erosion-resistant dust suppressant

A technology for building construction and rain erosion resistance, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor dust suppression effect of dust suppressants, achieve good film forming effect, excellent rain erosion resistance, and high durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

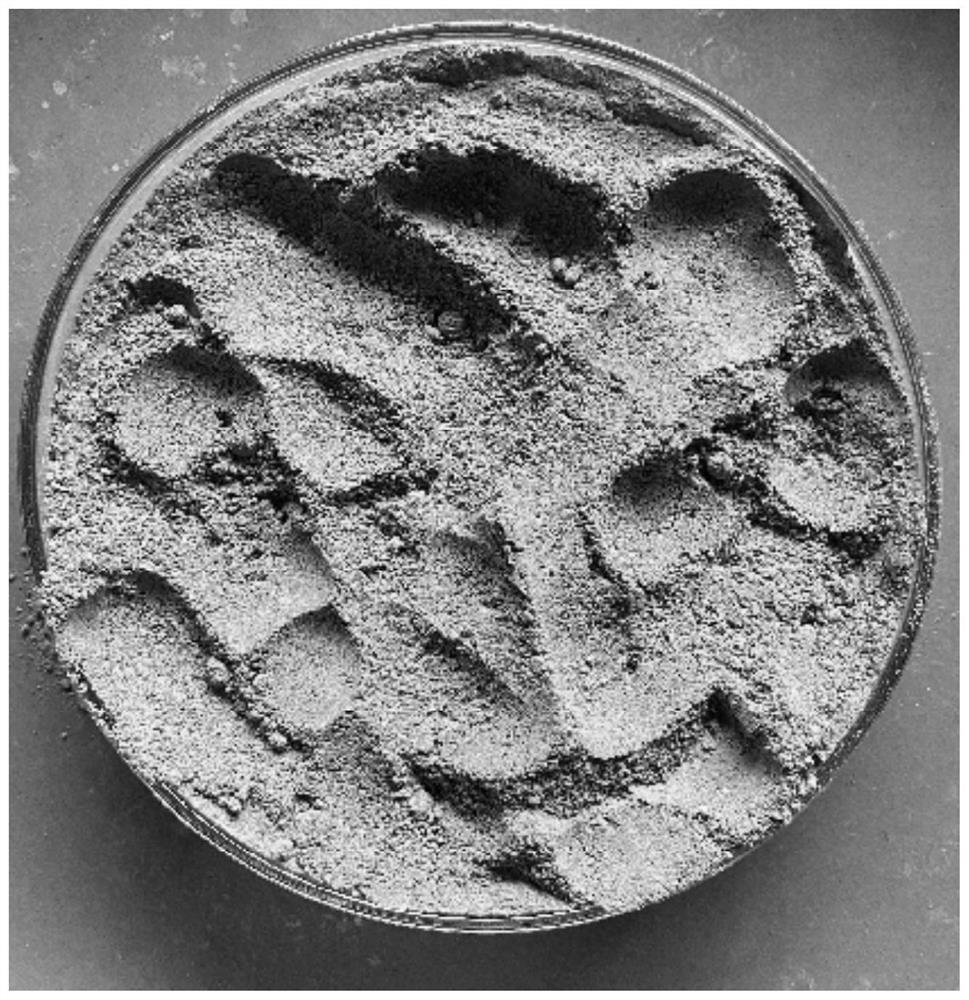

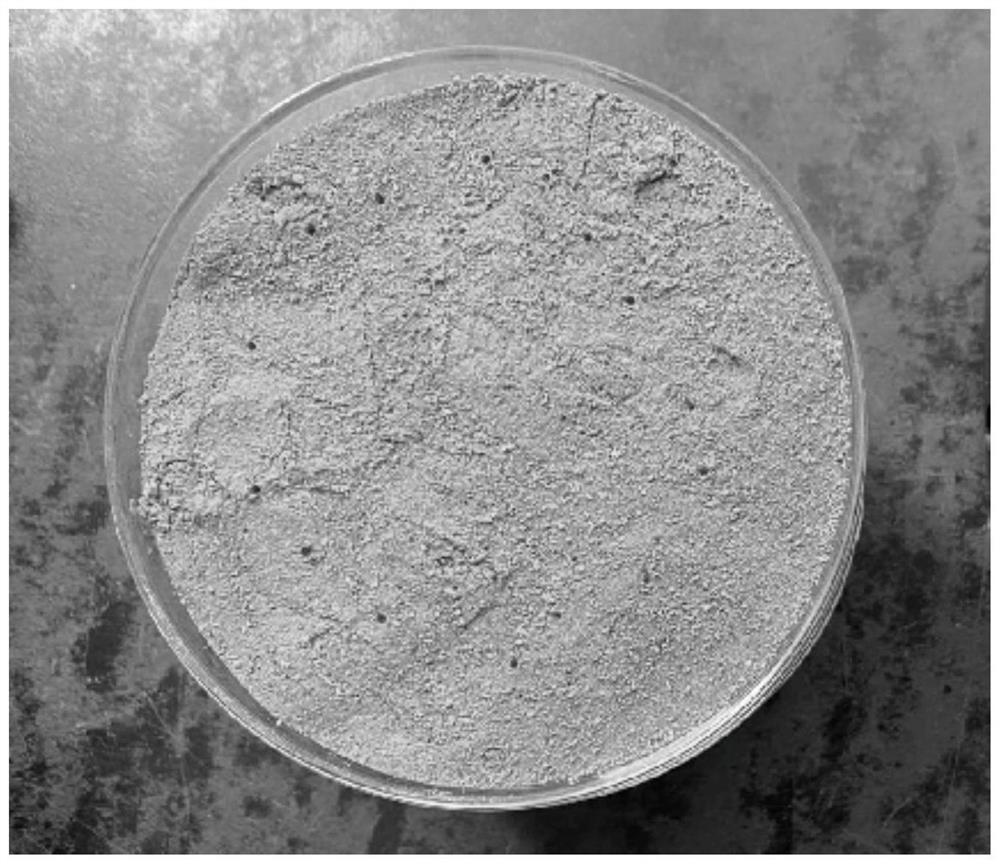

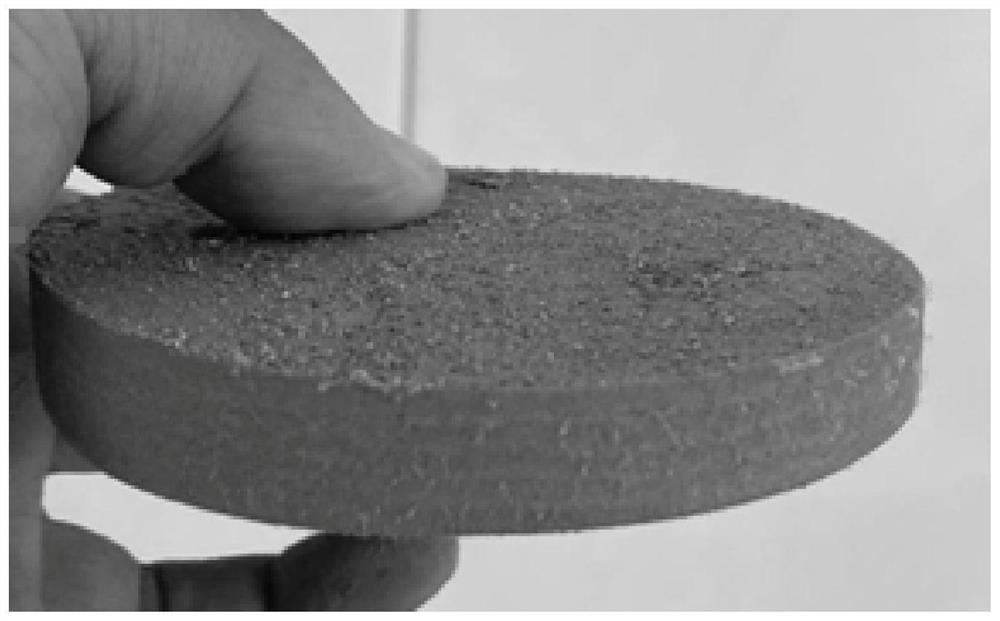

Image

Examples

Embodiment 1

[0051] A kind of anti-rain erosion dust suppressant for building construction, it is processed by the raw material that comprises the dosage shown in Table 1: Vegetable glue, water-based polymer emulsion, polyvinyl alcohol, sodium silicate, surfactant isomeric tridecanol Polyoxyethylene ether, silicone oil emulsion, hygroscopic agent triethanolamine, humectant glycerol, preservative N-(5-fluoropyridine)-D-glucopyranosesamine and water.

[0052] A preparation method of a rain erosion-resistant dust suppressant for building construction is prepared through the following operations:

[0053] Divide the water into 4 parts, add 3 / 4 of water, vegetable gum, water-based polymer emulsion, surfactant, hygroscopic agent, humectant and preservative to the first reaction tank, at 45 ℃, 700r / min , and continued to stir for 13 minutes to obtain the first mixed solution;

[0054] Add the remaining 1 / 4 water into the second reaction tank, and add polyvinyl alcohol and sodium silicate to the ...

Embodiment 2-4

[0057] The preparation method of the rain erosion-resistant and dust-suppressant of Examples 2-4 is the same as that of Example 1, the difference is that the dosage of each raw material is different, as shown in Table 1 for details.

[0058] Each raw material type and dosage (g) of the anti-rain erosion dust suppressant of table 1 embodiment 1-4

[0059]

Embodiment 5-10

[0061] The preparation method of the rain erosion-resistant and dust-suppressant of Examples 5-10 is the same as that of Example 1, the difference being that the types of components of vegetable glue are different, as shown in Table 2 for details, and the types and dosages of all the other raw materials are the same as those of Example 2. same.

[0062] Vegetable glue type and dosage (g) of the anti-rain erosion dust suppressant of table 2 embodiment 5-10

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com