Pilot-scale extraction method of plant-derived exosome and application of plant-derived exosome

A plant source and extraction method technology, applied in the field of plant source exosome extraction and enrichment purification, can solve the problems of limiting the application of plant exosomes, lack of efficient extraction methods of plant exosomes, etc., and achieve good application prospects and research Value, good cosmetic or therapeutic effect, effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

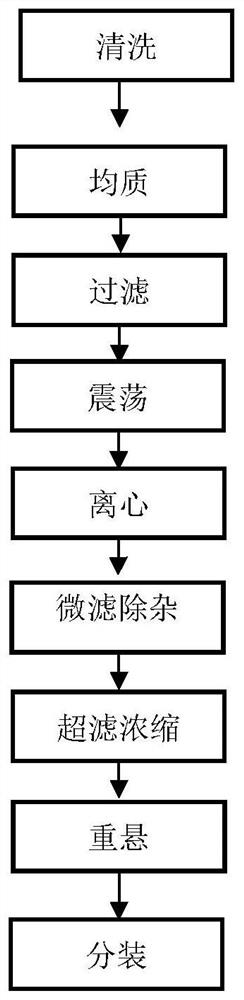

Method used

Image

Examples

Embodiment 1

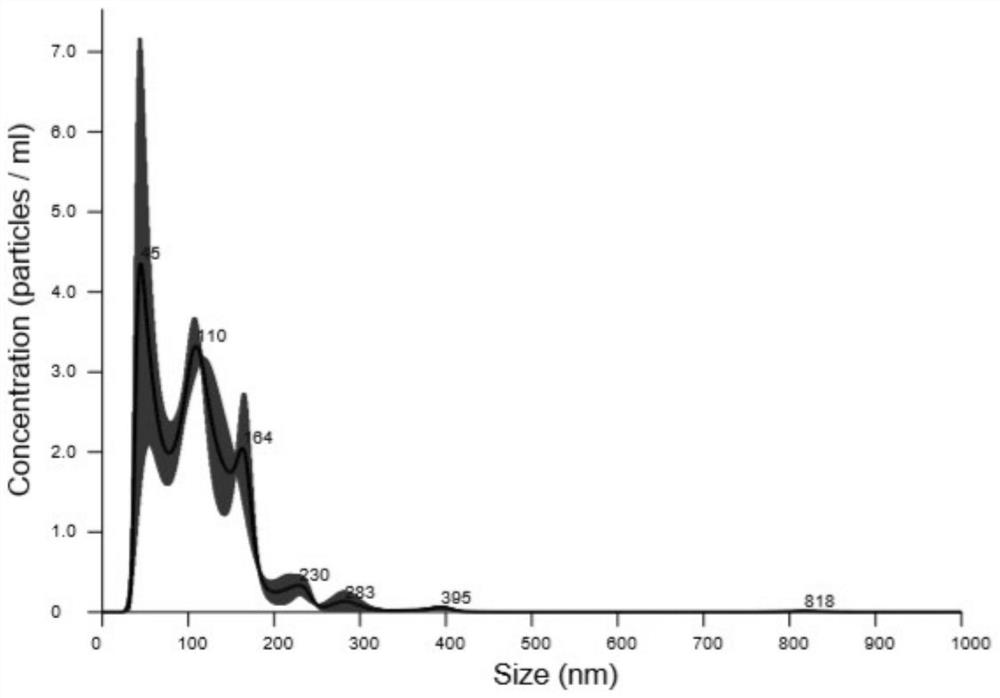

[0127] Lily exosome preparations: Example 1

[0128] Weigh fresh lily (including stem, leaves, flowers) 1 kg, washed three times with tap water, then rinsed three times with purified water, dry. Chopped, added juicer, was added 2000mL PBS buffer, homogenized 2 times. The residue was filtered with gauze large. Placed in shake flasks, shaken at a shaker for 24 hours, the temperature is 22 ℃, rotation speed of 100rpm. The mixture was centrifuged using a centrifuge 5000rpm 30min, the supernatant was collected. The supernatant was 0.45um hollow fiber ultrafiltration column, and then the filtrate was again 500kDa hollow fiber ultrafiltration column was concentrated to 300mL. Was added 75mL of PEG8000 / NaCl, mixed and left for 24 hours within a refrigerator at 4 ℃. 4000rpm, 4 ℃, centrifuged 10min, the precipitate was collected, resuspended with 30mL saline, filter sterilized 0.22um filter. Placed in -80 ℃ refrigerator storage. Protein concentrations were determined by Bradford method, t...

Embodiment 2

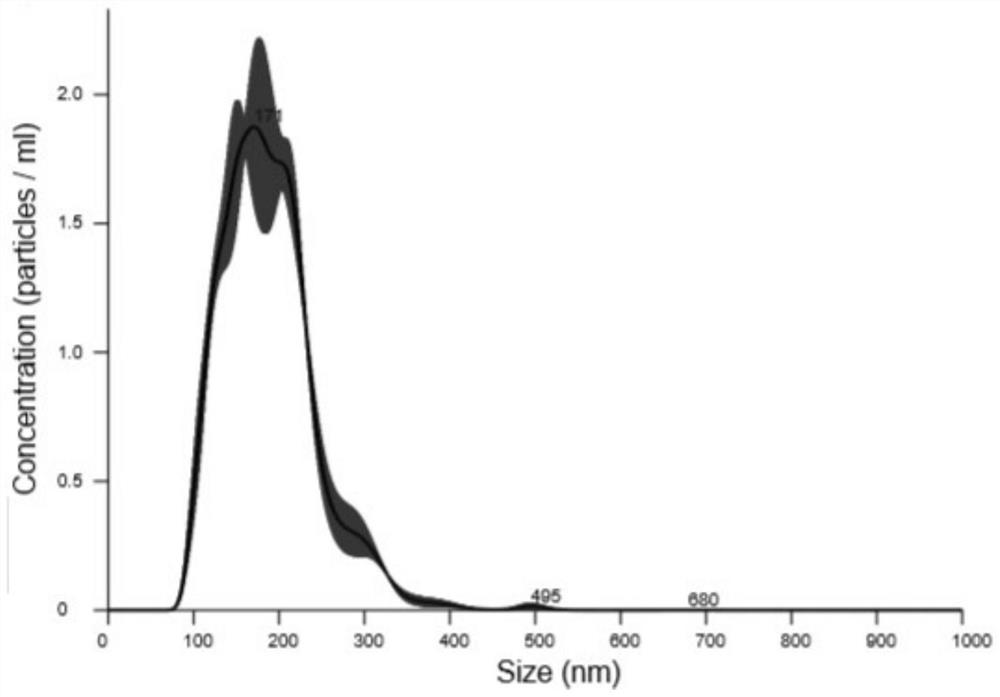

[0135] Seabuckthorn exosome preparations: Example 2

[0136] Weigh 2 kg of fresh sea buckthorn, washed 3 times with tap water, then rinsed three times with purified water, dry. Added juicer, was added 4000 mL PBS buffer, homogenized 3 times. The residue was filtered with gauze large. Placed in shake flasks, shaken at a shaker for 24 hours, the temperature is 25 ℃, speed of 120rpm. The mixture was centrifuged using a centrifuge 5000rpm 30min, the supernatant was collected. The supernatant was 0.45um hollow fiber ultrafiltration column, and then the filtrate was again 300kDa hollow fiber ultrafiltration column was concentrated to 400mL. Was added 100mL of PEG8000 / NaCl, mixed and left for 24 hours within a refrigerator at 4 ℃. 4000rpm, 4 ℃, centrifuged 15min, the precipitate was collected, resuspended with 40mL saline, filter sterilized 0.22um filter. Placed in -80 ℃ refrigerator storage. Protein concentrations were determined by Bradford method, to calculate the total amount of ex...

Embodiment 3

[0143] Example 3: Cistanche exosome preparations

[0144] Cistanche weighed 1 kg of dried, washed 3 times with tap water, then rinsed three times with purified water, dry. Added juicer, was added 5000mL PBS buffer, homogenized 3 times. The residue was filtered with gauze large. Placed in shake flasks, shaken at a shaker for 48 hours to a temperature of 24 ℃, rotation speed of 100rpm. The mixture was centrifuged using a centrifuge 5000rpm 30min, the supernatant was collected. The supernatant was 0.45um hollow fiber ultrafiltration column, and then the filtrate was again 300kDa hollow fiber ultrafiltration column was concentrated to 500mL. Was added 125mL of PEG8000 / NaCl, mixed and left for 24 hours within a refrigerator at 4 ℃. 4000rpm, 4 ℃, centrifuged 20min, the precipitate was collected, resuspended with 50mL saline, filter sterilized 0.22um filter. Placed in -80 ℃ refrigerator storage. Protein concentrations were determined by Bradford method, to calculate the total amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com