Flue gas conditioning device based on electric precipitator

A technology of electrostatic precipitator and wet electrostatic precipitator, which is applied in the direction of external electrostatic separator, electrostatic separation, steam flow control, etc., can solve the problems of excessive water droplets, the influence of the surrounding environment, and the difficulty in guaranteeing the treatment effect of water droplets, so as to ensure safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] see Figure 1-6 , an embodiment provided by the present invention:

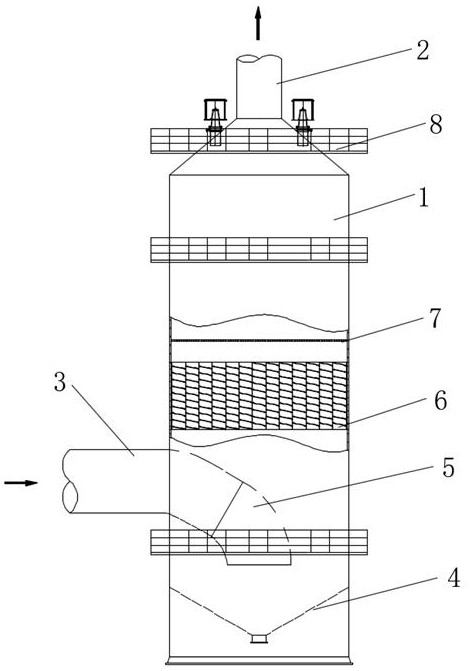

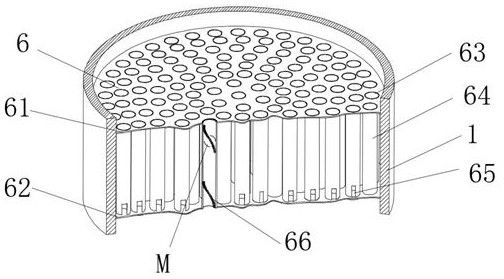

[0034] see figure 1, a flue gas conditioning device based on an electrostatic precipitator, comprising a flue gas channel 1, the upper end of the flue gas channel 1 is connected to an exhaust pipe 2, and the lower left side of the flue gas channel 1 is connected to an intake pipe 3, wherein the intake pipe 3 and The exhaust pipe 2 communicates with the inner cavity of the flue gas channel 1 . The flue gas enters the flue gas passage 1 from one end of the intake pipe 3 , and is discharged through the exhaust pipe 2 after being processed inside the flue gas passage 1 . Inside the flue gas channel 1, there are flow guides 4, humidity control devices 6, distribution plates 7 and wet electrostatic precipitators 8 in sequence from bottom to top, wherein the flow guides 4 are funnel-shaped, which can facilitate the water droplet in the flue gas. After the flue gas is distributed through the integrated cond...

Embodiment 2

[0043] see Figure 7 and 8 , the difference between this embodiment and embodiment 1 is:

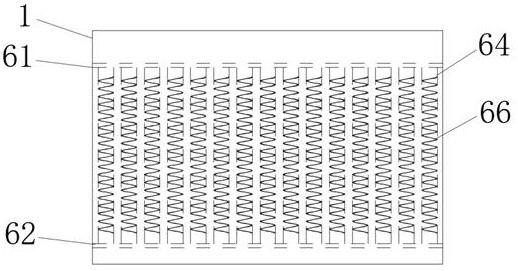

[0044] see Figure 6 , a corrugated spiral mesh 10 is provided inside the cylinder 64, and the spiral mesh 10 is fixed on the cylinder 64. In the above, when the smoke passes through the smoke humidity conditioning strip 66, the smoke will move forward in a spiral shape, so As a result, the flue gas in the middle cannot be effectively dehumidified, and the spiral net 10 arranged inside the cylinder 64 can collide with the spiral net 10 when the flue gas advances in a spiral shape, and collect water droplets on the spiral net 10. And it drips down automatically through the spiral net 10, so that the dehumidification of the flue gas is uniform enough to ensure the conditioning effect of the flue gas.

[0045] see Figure 7 , wherein, the distribution of the cylinder 64 inside the flue gas channel 1 adopts a cylinder 64 with a smaller diameter in the middle and a cylinder 64 with a larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com