Cross-linked cationic reverse demulsifier and preparation method thereof

A reverse-phase demulsifier and cationic technology, which is applied in chemical dehydration/demulsification, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of poor water cleaning speed and effect, poor adaptability, single functional group, etc., to achieve Effect enhancement, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

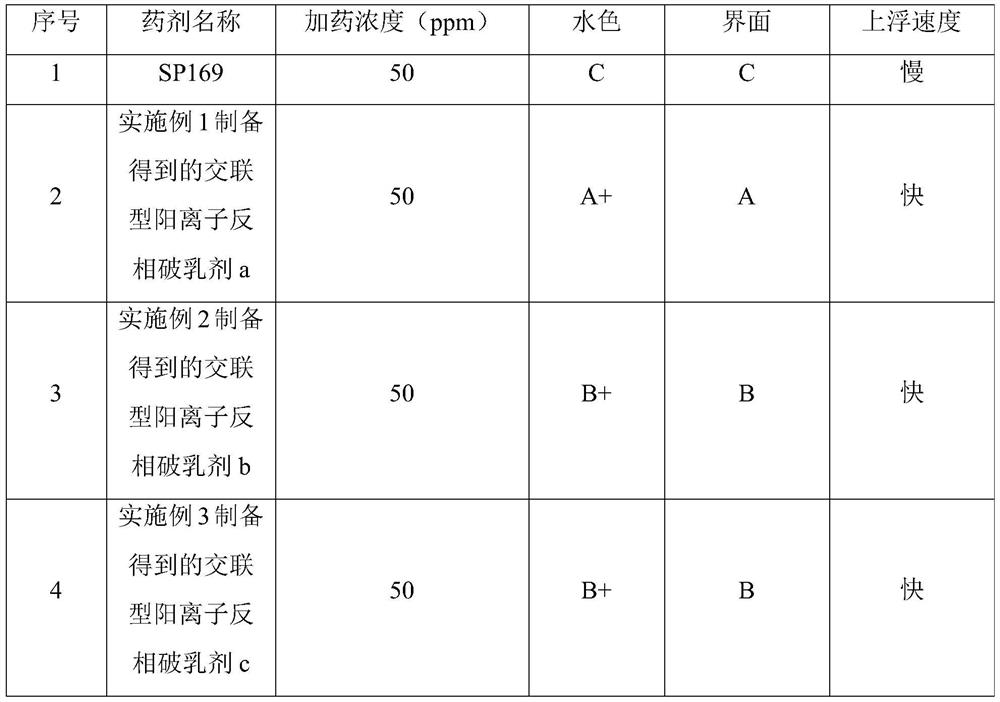

Examples

Embodiment 1

[0019] First, take 200g of polyether, dissolve 8g of potassium hydroxide in 8g of distilled water, add it into a four-neck flask, mix well, raise the temperature to 60°C, and stir for 1h; at this time, weigh 12g of epichlorohydrin and add it to the burette , start dropwise at 60°C, after 1h of dropping time, raise the temperature to 80°C, and react for 3h; dissolve 8g of potassium hydroxide in 8g of distilled water, add it into a four-neck flask, mix well, cool to 60°C, stir 1h; Dissolve 19.6g of 2,3-epoxypropyltrimethylammonium chloride in 19.6g of distilled water, add it to the burette, start dropping at 60°C, and after the dropping time is 1h, raise the temperature to 80°C , reacted for 3 hours; cooled to 40° C., and added 210 g of 75% ethanol solution to obtain a cross-linked cationic inverse demulsifier a with a solid content of 50%.

Embodiment 2

[0021] First, take 200g of polyether, dissolve 3g of potassium hydroxide in 3g of distilled water, add it into a four-neck flask, mix well, raise the temperature to 60°C, and stir for 1h; at this time, weigh 4g of epichlorohydrin and add it to the burette , start dropwise at 60°C, after 1h of dropping time, raise the temperature to 80°C, and react for 3h; dissolve 3g of potassium hydroxide in 3g of distilled water, add it into a four-neck flask, mix well, cool to 60°C, stir 1h; Dissolve 3.9g of 2,3-epoxypropyltrimethylammonium chloride in 3.9g of distilled water, add it to the burette, and start dropping at 60°C. After the dropping time is 1h, raise the temperature to 80°C , reacted for 3 hours; cooled to 40° C., and added 200 g of 75% ethanol solution to obtain a cross-linked cationic inverse demulsifier b with a solid content of 50%.

Embodiment 3

[0023] First, take 200g of polyether, dissolve 5.8g of potassium hydroxide in 5.8g of distilled water, add it into a four-neck flask, mix well, raise the temperature to 60°C, and stir for 1 hour; at this time, weigh 8g of epichlorohydrin, add In the burette, start dropwise at 60°C, after 1h of dropping time, raise the temperature to 80°C, and react for 3h; dissolve 2.4g of potassium hydroxide in 2.4g of distilled water, add it into a four-necked flask, mix well, and cool to Stir at 60°C for 1h; dissolve 6.5g of 2,3-epoxypropyltrimethylammonium chloride in 6.5g of distilled water, add it to the burette, start dropping at 60°C, and drop it for 1h. Raise the temperature to 80° C., react for 3 hours; cool to 40° C., add 210 g of 75% ethanol solution to obtain a cross-linked cationic inverse demulsifier c with a solid content of 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com