Three-dimensional electrode material formed by carbon-coated nanosheets and preparation method

A three-dimensional electrode and nanosheet technology, used in carbon preparation/purification, battery electrodes, nanotechnology, etc., can solve problems such as poor charge and discharge stability, achieve good rate performance, high yield, and improve high current charge and discharge. Effects of Cyclic Stable Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

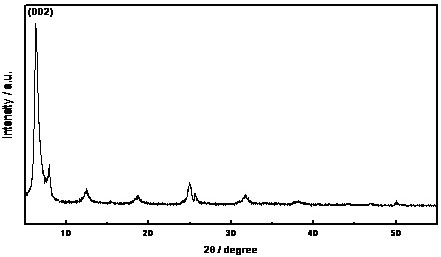

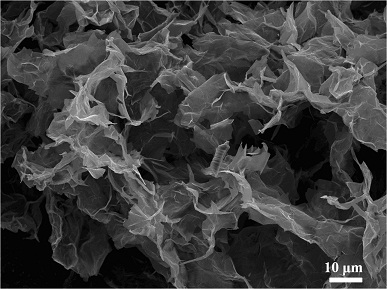

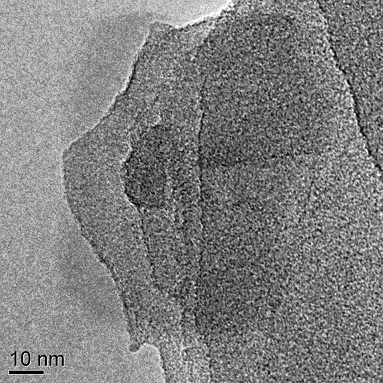

[0014] Add about 0.36 grams of V to a 100ml glass beaker 2 o 5 Powder, then add about 30ml of deionized water, stir evenly, then add about 5ml of commercially available about 30% hydrogen peroxide solution, stir again, and then ultrasonically treat in a water bath for about 15 minutes, during which a large amount of bubbles, and the solution turns red and transparent at the same time. When the bubbles are basically no longer generated, add about 0.03ml of absolute ethanol to the red transparent solution, stir well and let it stand for about 8 hours. After about 8 hours, the solution turns light yellow. Then pour the light yellow solution into a 50ml polytetrafluoroethylene liner at 160 o After hydrothermal treatment at a temperature of C for about 12 hours, a grass-green colloidal product can be obtained. Dissolve the grass-green colloidal product after the hydrothermal reaction in about 500ml of deionized water for washing, separate the solid and solution by natural sedimen...

Embodiment 2

[0016] Add about 0.72 grams of V to a 200ml glass beaker 2 o 5 Powder, then add about 60ml of deionized water, stir evenly, then add about 10ml of commercially available about 30% hydrogen peroxide solution, stir again, and then ultrasonically treat for about 30 minutes in a water bath, during which a large amount of bubbles, and the solution turns red and transparent at the same time, when it is left to no longer generate bubbles, add about 0.06ml of isopropanol to the red transparent solution, stir evenly and let it stand for about 12 hours, the solution turns light yellow, put The light yellow solution is put into a 100ml polytetrafluoroethylene liner, at 180 o After hydrothermal treatment at a temperature of C for about 12 hours, a grass-green colloidal product can be obtained. Dissolve the grass-green colloidal product after the hydrothermal reaction in deionized water for washing, separate the solid and solution by natural sedimentation or high-speed centrifugation, po...

Embodiment 3

[0018] Add about 0.72 grams of V to a 200ml glass beaker 2 o 5 Powder, then add about 50ml of deionized water, stir evenly, then add about 8ml of commercially available about 30% hydrogen peroxide solution, stir again, and then ultrasonically treat in a water bath for about 20 minutes, during which a large amount of Bubbles, and the solution turns red and transparent at the same time, when it is placed until no more bubbles are generated, add about 0.08ml of a mixed solution of methanol, ethanol and isopropanol to the red transparent solution, wherein the mixed solution contains methanol, ethanol and The volume ratio of isopropanol is 1:1:1. After stirring evenly and standing for about 8 hours, the solution turns light yellow. Put the light yellow solution into a 100ml polytetrafluoroethylene liner, o After hydrothermal treatment at a temperature of C for about 14 hours, a grass-green colloidal product can be obtained. Dissolve the grass-green colloidal product after the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com