Method for purifying indole-3-lactic acid in plant lactobacillus fermentation supernatant

A technology of plant lactic acid bacteria and fermentation supernatant is applied in the field of extracting indole-3-lactic acid from plant lactic acid bacteria fermentation supernatant, and can solve the problems of different mechanical properties of filters, differences in indole-3-lactic acid content and purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Determination of indole-3-lactic acid content in the fermentation supernatant of Lactobacillus plantarum ZJ316

[0051] (1) Streak the Lactobacillus plantarum ZJ316 strain on the MRS solid medium, culture at 37°C for 36h, pick a single colony and culture it in 10mL MRS liquid medium at 37°C for 24h;

[0052] (2) Inoculate the culture solution obtained in step (1) into 150 mL MRS liquid medium with 3% inoculum size (volume concentration) and continue to culture at 37° C. for 24 hours;

[0053] (3) The culture solution obtained in step (2) was inoculated with 3% inoculation amount (volume concentration) in 5L MRS liquid medium for fermentation. Fermentation conditions: temperature 37°C, rotation speed 180rpm, time 24h.

[0054] The obtained fermentation broth was centrifuged: 8000rpm, 25min, 4°C, and the fermentation supernatant was stored at 4°C until use.

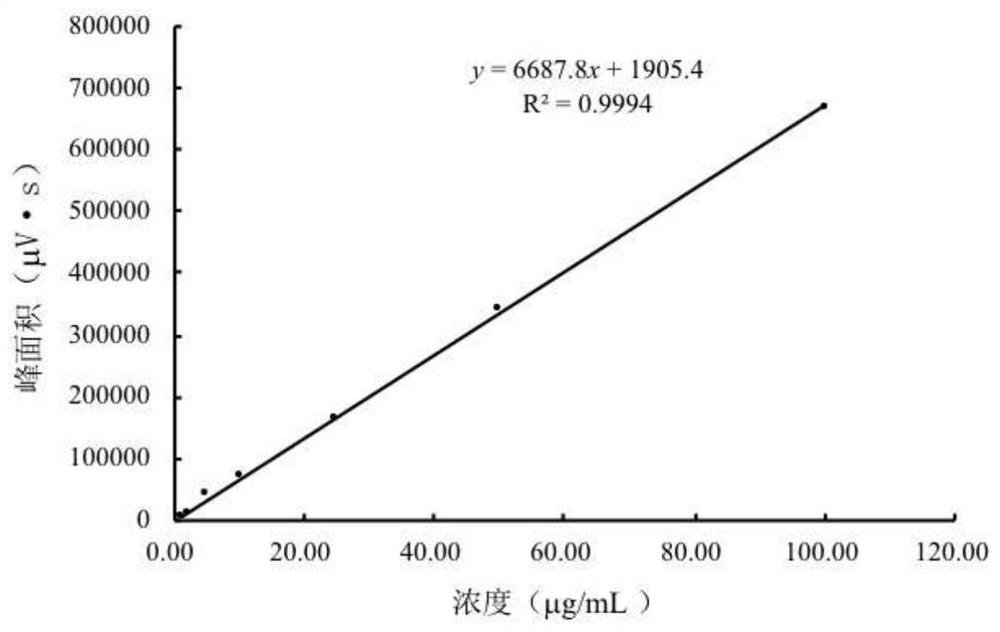

[0055] (4) Ultraviolet detection conditions: detector model Waters 2498, detector wavelength: 280n...

Embodiment 2

[0063] Example 2: Separation, purification and identification of indole-3-lactic acid

[0064] Step 1: Adsorption and elution of macroporous resin XAD-16

[0065] (1) 5L Lactobacillus plantarum ZJ316 fermentation supernatant (gained in step (3) of embodiment 1) is adsorbed by 500g macroporous resin XAD-16, and the flow rate is 1mL / min; Then use 2L ultrapure water, 30% methanol , 50% methanol (37.5% concentrated hydrochloric acid to adjust pH=7), the flow rate is 1mL / min, collect the eluent (about 2L) corresponding to 50% methanol with pH=7;

[0066] (2) Concentrate the eluent (50% methanol eluent) obtained in step (1) to 200mL with a rotary evaporator to obtain a concentrated solution; rotary evaporation conditions: water bath temperature 37°C, pressure 30±5mbar, rotation speed 60rpm .

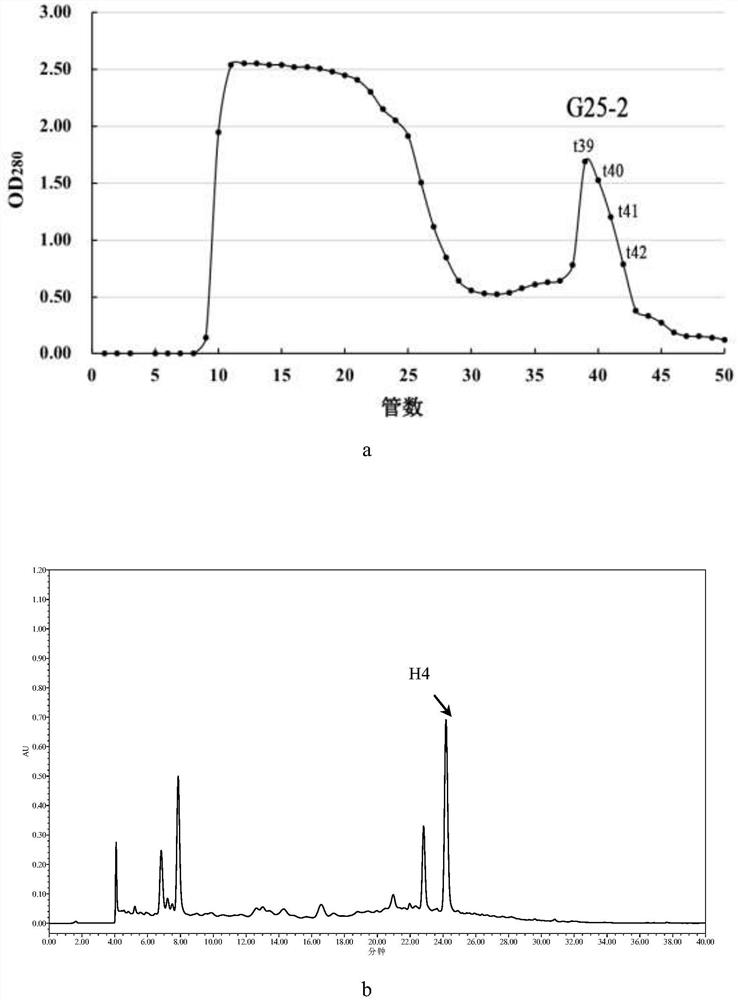

[0067] Step 2: Separation on Sephadex G25 Sephadex Gel Column

[0068] (1) Sephadex G25 Sephadex column was used for column separation of the concentrate obtained in step 1 (column height 8...

Embodiment 3

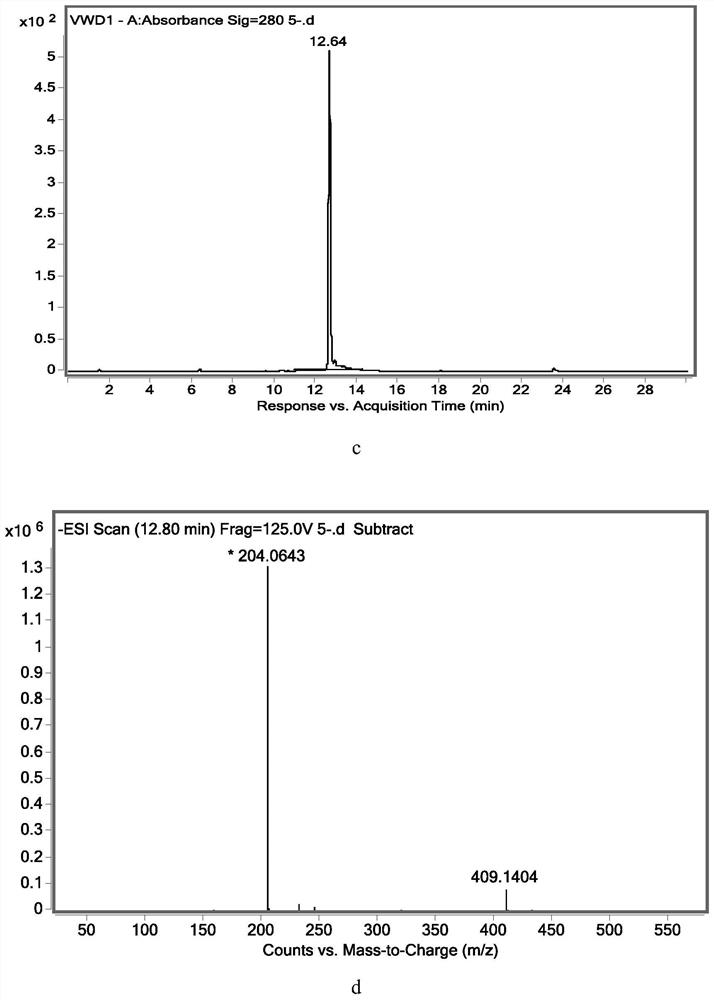

[0094] Example 3: Purity determination of isolated and purified indole-3-lactic acid

[0095] Take the concentrated sample "H4" of Step 3 of Example 2, and obtain the chromatogram of indole-3-lactic acid according to the analytical HPLC detection conditions and elution procedures described in Step (5) of Example 1, as shown in image 3 shown. Table 4 shows the starting and ending time (min), peak area (μV·s) and peak area ratio (%) of the main component peak (ie, indole-3-lactic acid) and two miscellaneous peaks. According to the peak area normalization method, the main component peak (i.e., indole-3-lactic acid) area is A, and the sum of the main component peak and other miscellaneous peak peak areas is ΣA, and the indole-3-lactic acid purity (%) is obtained. Calculation formula:

[0096] Indole-3-lactic acid purity (%)=A / ∑A×100%.

[0097] Table 4, the peak area of HPLC chromatographic peak

[0098]

[0099] Therefore, through the separation and purification of steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com