Microencapsulated flame retardant and preparation method thereof

A technology of microencapsulation and flame retardants, which is applied in the field of microencapsulation flame retardants and its preparation, can solve problems such as poor water resistance, limited application range, poor compatibility between flame retardants and polymer materials, and reduce Side reactions, simple and fast process, and the effect of improving the efficiency of microencapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation method of polyurea microcapsule phosphate (AHP), by the following steps:

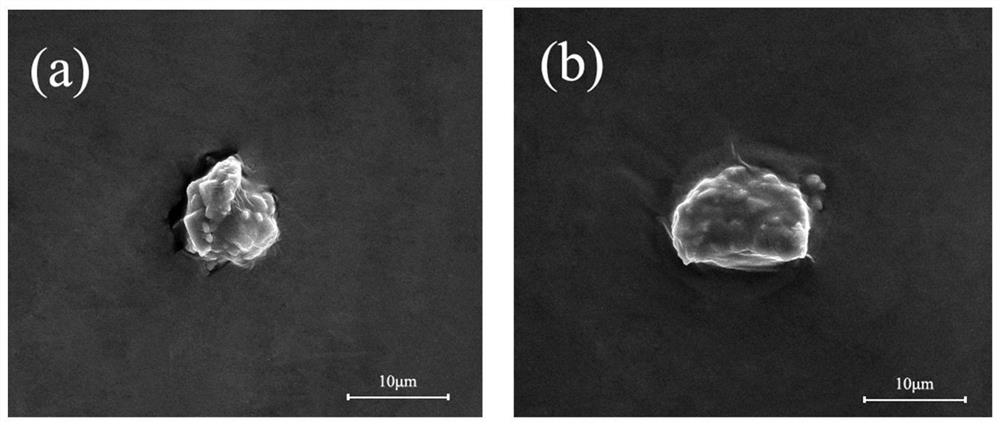

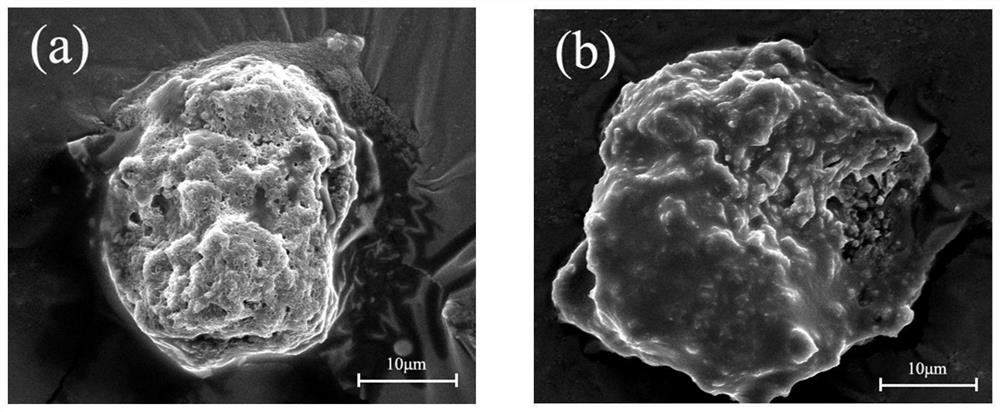

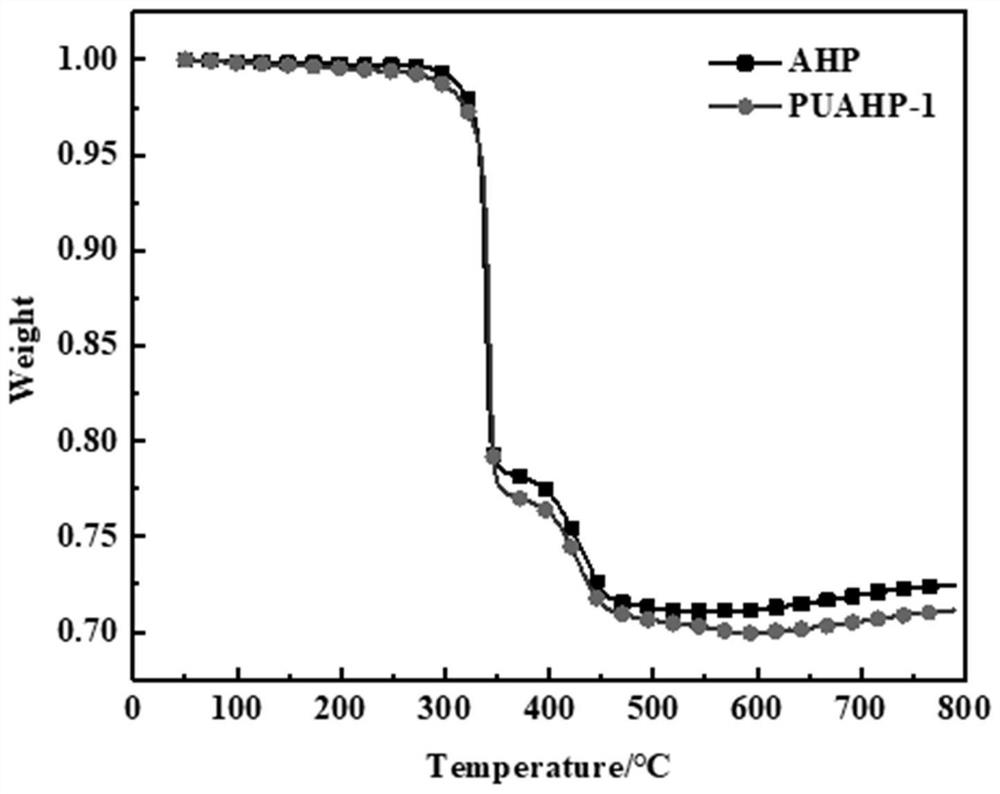

[0027] (1) Pre-treatment of AHP: Take a certain amount of AHP (its SEM image is like figure 1 A shown in the four flask, then deionized water, divinisin, emulsifier Tween 80 sequentially added in the four flasks, and the amount of Tween 80 and the divinisinis is AHP quality, respectively. 6% and 1.3%, the mass ratio of deionized water and AHP was 3.5: 1, and the mixture was mixed even after the addition was completed, and the pretreatment of AHP was obtained.

[0028] (2) Preparation of oil-in-water emulsion: Press the ratio of deionized water and cyclohexane to 1: 4, and cyclohexane is added to the AHP pre-treatment solution obtained in step (1), and adjust the speed. It was 1200 rpm, stirred vigorously for about 20 min to give an AHP oil-in-water emulsion.

[0029] (3) Preparation of polyurea microcapsules AHP: Add a curing agent isoopretone diisocyanate (IPDI) in the oil-in-water emuls...

Embodiment 2

[0033] Preparation method of polyurea microcapsules AHP, achieved by the following steps:

[0034](1) Pre-treatment of AHP: Take a certain amount of AHP in four flasks, then subsequently adding deionized water, divinisin, emulsifier Tween 80 in four flasks, including Tween 80 and Diethylene The amount of triamine is 7% and 1.3% of aluminum phosphate, the mass ratio of deionized water and AHP is 3.5: 1, and the mixture is mixed even after the addition is completed, and the pre-treatment liquid of AHP is obtained.

[0035] (2) Preparation of oil-in-water emulsion: Press the ratio of deionized water and cyclohexane to 1: 4, and cyclohexane is added to the AHP pre-treatment solution obtained in step (1), and adjust the speed. It was 1200 rpm, stirred vigorously for about 20 min to give oil-in-water emulsion.

[0036] (3) Preparation of polyurea microcapsule AHP: The cyclohexane solution of the curing agent IPDI is added to the oil-in-water emulsion prepared in the step (2), and the am...

Embodiment 3

[0039] Preparation method of polyurea microcapsules AHP, achieved by the following steps:

[0040] (1) Pre-treatment of AHP: Take a certain amount of AHP in four flasks, then subsequently adding deionized water, divinisin, emulsifier Tween 80 in four flasks, including Tween 80 and Diethylene The amount of triamine is 4% and 2% of the secondary phosphate mass, the mass ratio of deionized water and AHP is 3.5: 1, and the mixture is mixed even after the addition is completed, and the pre-treatment liquid of AHP is obtained.

[0041] (2) Preparation of oil-in-water emulsion: Press the ratio of deionized water and cyclohexane to 1: 4, and cyclohexane is added to the AHP pre-treatment solution obtained in step (1), and adjust the speed. It was 1200 rpm, stirred vigorously for about 20 min to give oil-in-water emulsion.

[0042] (3) Preparation of polyurea microcapsules AHP: The cyclohexane solution of the curing agent IPDI is added to the oil-in-water emulsion prepared in the step (2), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com