UV nano black slurry and preparation method and application thereof

A kind of technology of black pulp and nano, which is applied in the field of UV nano black pulp and its preparation, can solve the problems of low rubbing fastness and low blackness of nano black pulp, achieve high grinding efficiency, improve rubbing color fastness, brightness and blackness excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

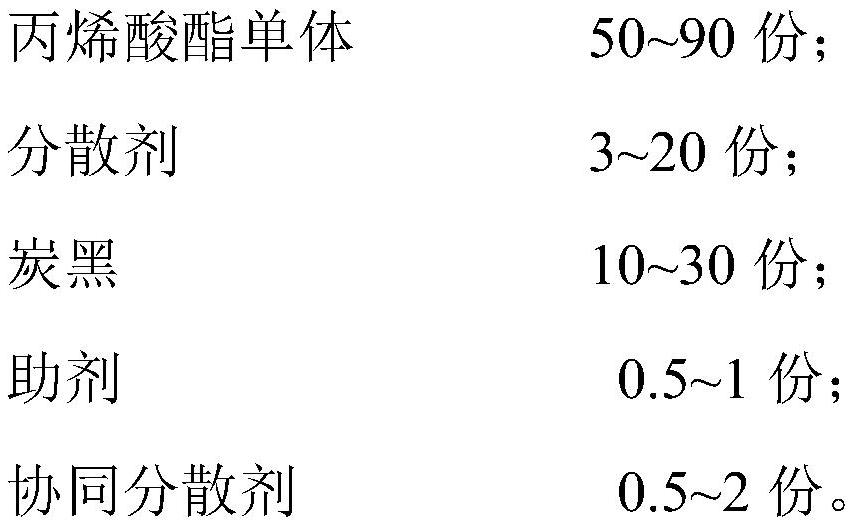

[0044] The second aspect of the embodiment of the present application provides a method for preparing UV nano black paste, comprising the following steps:

[0045] S01. Provide various components according to UV nano black paste;

[0046] S02. Performing a first mixing treatment on the acrylate monomer and the dispersant to obtain a first mixture;

[0047] S03. Carrying out the second mixing treatment of the first mixture with carbon black, auxiliary agent and co-dispersant to obtain the second mixture;

[0048] S04. The second mixture is sequentially subjected to coarse grinding and fine grinding to obtain a third mixture;

[0049] S05. The third mixture is filtered to obtain UV nano black slurry.

[0050] The preparation method of the UV nano-black slurry provided by the second aspect of the application, in this preparation method, the components are firstly mixed to obtain a mixture, and then the mixture is subjected to rough grinding and fine grinding in turn, and the ro...

Embodiment 1

[0074] A kind of UV nano black paste and preparation method thereof

[0075] Wherein, each component of the UV nano-black paste provided in Example 1 and the number of additions are as shown in Example 1 in Table 1.

[0076] The preparation method is as follows: provide each component according to the UV nano black paste provided in Example 1;

[0077] performing the first mixing treatment on the acrylate monomer and the dispersant to obtain the first mixture;

[0078] performing a second mixing treatment on the first mixture with carbon black, an auxiliary agent, and a co-dispersant to obtain a second mixture;

[0079] The second mixture is subjected to coarse grinding treatment and fine grinding treatment in turn to obtain the third mixture; wherein, in the step of coarse grinding treatment, it includes: providing a sand mill, and using zirconium beads for coarse grinding treatment, wherein the filling amount of zirconium beads is 70~90%, the particle size of zirconium bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com