Antibacterial polyester combined fiber elastic yarn and preparation method thereof

A technology of elastic yarn and blended fiber, which is applied in the field of spinning, can solve the problems of elastic yarn’s adverse effect on elasticity, resistance to washing, affecting the spinnability and other properties of thermoplastic chemical fiber filaments, etc., to improve antibacterial ability and washing resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

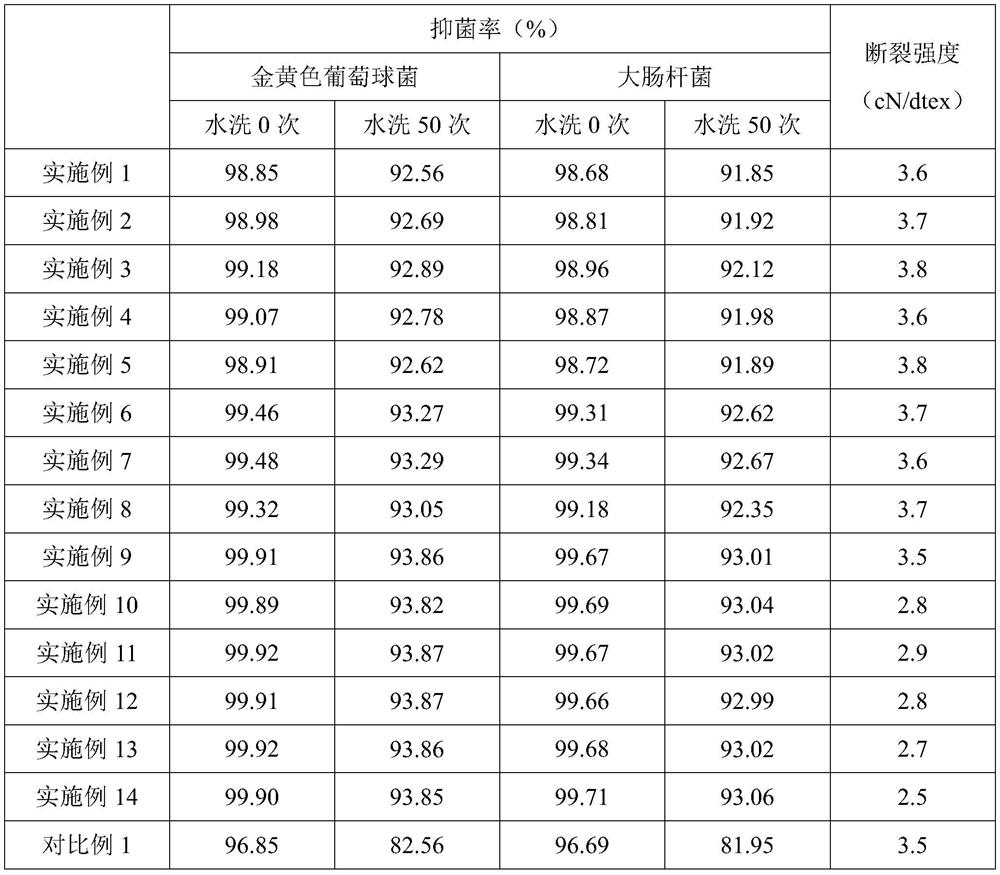

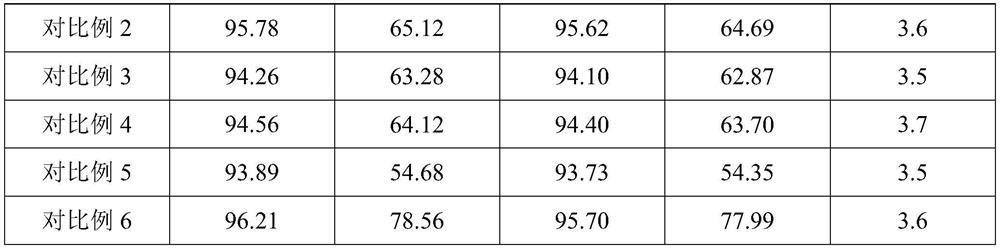

Examples

preparation example Construction

[0030] Preparation Examples of Raw Materials and Intermediates

[0031] raw material

[0032] The weight average molecular weight of polyhexamethyleneguanidine hydrochloride is 8200 g / mol.

preparation example 1

[0035] The preparation method of glycerol triglycidyl ether modified polyhexamethylene guanidine hydrochloride:

[0036] Mix 200g of polyhexamethyleneguanidine hydrochloride with 900g of dimethyl sulfoxide, dissolve with ultrasonic assistance to obtain a mixed solution, then add 110g of glycerol triglycidyl ether to the mixed solution, and react at 50°C for 10h , to obtain the reaction solution, slowly pour the reaction solution into acetone, the volume ratio of the reaction solution to acetone is 1:10, flocculent precipitates appear, then centrifuge for 10min, pour off the supernatant, wash the precipitate twice with acetone, remove unreacted glycerol triglycidyl ether to obtain glycerol triglycidyl ether modified polyhexamethylene guanidine hydrochloride.

preparation example 2

[0038] Preparation method of polyhexamethyleneguanidine hydrochloride supported on hollow nano-silica:

[0039] Weigh 80g of hollow nano-silica and ultrasonically disperse it in 32L deionized water to obtain a hollow nano-silica dispersion, weigh 200g of polyhexamethyleneguanidine hydrochloride and dissolve it in 8L of deionized water to obtain polyhexamethylene guanidine hydrochloride. Methyleneguanidine hydrochloride aqueous solution, adding polyhexamethyleneguanidine hydrochloride aqueous solution to the hollow nano-silica dispersion, stirring magnetically at 25°C for 24 hours, centrifuging and washing with deionized water for 5 times, drying, The polyhexamethyleneguanidine hydrochloride supported on the hollow nano-silica is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com