Application of phospholipid in reducing friability of kelp dietary fiber tablet and improving taste

A dietary fiber sheet and dietary fiber technology, applied in the direction of food ingredients as taste improvers, applications, functions of food ingredients, etc., can solve the problems of inability to fully exert activity, low entrapment capacity of egg yolk lecithin, and sodium alginate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

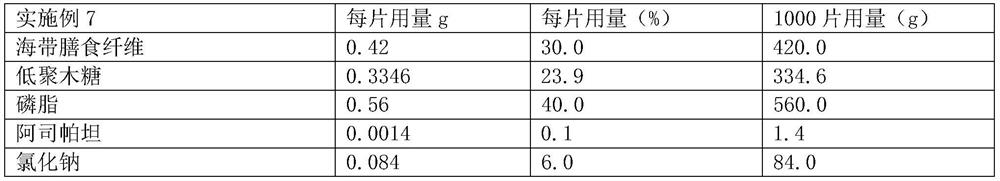

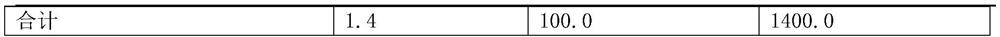

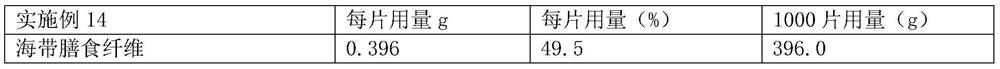

[0061] Embodiment 1 prescription

[0062] Example 1 Dosage per tablet g Amount per tablet (%) Dosage for 1000 tablets (g) Kelp Dietary Fiber 0.686 49.0 686.0 Xylooligosaccharide 0.35 25.0 350.0 Phospholipids 0.35 25.0 350.0 Calcium stearate 0.014 1.0 14.0 total 1.4 100.0 1400.0

[0063] Process: a) pass the kelp dietary fiber through a 200-mesh sieve for later use; b) weigh the prescribed amount of kelp dietary fiber, xylo-oligosaccharides, and phospholipids and mix evenly; c) add an appropriate amount of purified water to soften the powder, and use a 14-mesh sieve to granulate , placed in an oven at 50°C-60°C for 1-2h; d) Take out and use a 14-mesh sieve to granulate, add the prescribed amount of lubricant (calcium stearate) and then mix; e) Compression: according to the regulations Tablet weight tablet.

Embodiment 2

[0064] Embodiment 2 prescription

[0065] Example 2 Dosage per tablet g Amount per tablet (%) Dosage for 1000 tablets (g) Water Soluble Kelp Dietary Fiber 0.42 30.0 420.0 Xylooligosaccharide 0.56 40.0 560.0 Soy lecithin 0.4172 29.8 417.2 Magnesium stearate 0.0028 0.2 2.8 total 1.4 100.0 1400.0

[0066] Process: a) water-soluble kelp dietary fiber is passed through a 180-mesh sieve for later use; b) water-soluble kelp dietary fiber, xylo-oligosaccharides, and soybean phospholipids are weighed to mix evenly; Granulate with a 16-mesh sieve, put it into an oven at 50°C-60°C and dry it by air for 1-2 hours; d) take it out and granulate it with a 16-mesh sieve, add the prescribed amount of lubricant (magnesium stearate) and mix it; e) Tablet compression: according to the prescribed tablet weight.

Embodiment 3

[0067] Embodiment 3 prescription

[0068] Example 3 Dosage per tablet g Amount per tablet (%) Dosage for 1000 tablets (g) Kelp Dietary Fiber 0.98 70.0 980.0 Isomaltooligosaccharide 0.14 10.0 140.0 egg yolk lecithin 0.196 14.0 196.0 Leucine 0.084 6.0 84.0 total 1.4 100.0 1400.0

[0069] Process: a) Pass the kelp dietary fiber through a 150-mesh sieve for later use; b) Weigh the prescribed amount of kelp dietary fiber, isomalto-oligosaccharide, and egg yolk lecithin and mix evenly; Granulate and dry in an oven at 50°C-60°C for 1-2 hours; d) Take out and sieve the granules with 18 mesh, add the prescribed amount of lubricant (leucine) and mix them; e) Tablet compression: according to Tablet weight is prescribed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com