Processing technology of fixed denture

A fixed denture and processing technology technology, applied in the field of denture processing, can solve the problems of high processing cost, long processing time, poor cutting performance, etc., achieve the effect of convenient and fast processing, improve processing accuracy, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

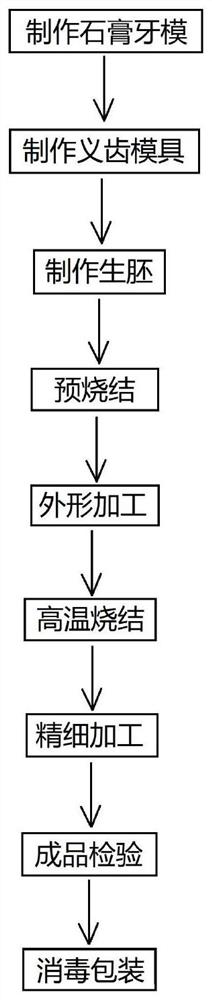

[0030] A processing technology for fixed dentures, such as figure 1 shown, including the following steps:

[0031] S1. Make a plaster dental mold: make a plaster dental mold with the same shape and structure as the internal tooth shape of the patient's oral cavity according to the impression film obtained from the patient's mouth;

[0032] S2. Making denture molds: use a 3D scanner to scan the gypsum dental mold in 3D, and then process and modify the denture surface according to the design requirements to construct a 3D model of the denture, and then use a 3D printer to prepare a denture mold based on the constructed 3D model of the denture. ;

[0033] S3. Making green embryos: filling the denture mold with ceramic powder, and then placing the denture mold in an isostatic press for isostatic pressing to obtain green dentures. The control pressure during the isostatic pressing molding process is 160MPa , keep the pressure for 7 minutes and release the pressure;

[0034] S4. ...

Embodiment 2

[0042] A processing technology for fixed dentures, comprising the following steps:

[0043] S1. Make a plaster dental mold: make a plaster dental mold with the same shape and structure as the internal tooth shape of the patient's oral cavity according to the impression film obtained from the patient's mouth;

[0044] S2. Making denture molds: use a 3D scanner to scan the gypsum dental mold in 3D, and then process and modify the denture surface according to the design requirements to construct a 3D model of the denture, and then use a 3D printer to prepare a denture mold based on the constructed 3D model of the denture. ;

[0045] S3. Making green embryos: filling the denture mold with ceramic powder, and then placing the denture mold in an isostatic press for isostatic pressing to obtain green dentures. The control pressure during the isostatic pressing molding process is 120MPa , keep the pressure for 10 minutes and release the pressure;

[0046] S4. Pre-sintering: put the ...

Embodiment 3

[0054] A processing technology for fixed dentures, comprising the following steps:

[0055] S1. Make a plaster dental mold: make a plaster dental mold with the same shape and structure as the internal tooth shape of the patient's oral cavity according to the impression film obtained from the patient's mouth;

[0056] S2. Making denture molds: use a 3D scanner to scan the gypsum dental mold in 3D, and then process and modify the denture surface according to the design requirements to construct a 3D model of the denture, and then use a 3D printer to prepare a denture mold based on the constructed 3D model of the denture. ;

[0057] S3. Making green embryos: filling the denture mold with ceramic powder, and then placing the denture mold in an isostatic press for isostatic pressing to obtain green dentures. The control pressure during the isostatic pressing molding process is 180MPa , keep the pressure for 5 minutes and release the pressure;

[0058] S4. Pre-sintering: put the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com