Solid acid catalyst and preparation method thereof, and alkylation reaction method

A solid acid catalyst and catalyst technology, applied in catalyst activation/preparation, catalyst, molecular sieve catalyst, etc., can solve the problems of short catalyst cycle life and low target product selectivity, and achieve small unit cell shrinkage and target product selectivity High, reduce the effect of high temperature roasting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] As previously mentioned, the first aspect of the present invention provides a method for preparing a solid acid catalyst, the method comprising:

[0022] (1) Mix sodium-type molecular sieves with alumina or its precursors, other heat-resistant inorganic oxides or their precursors, acid solution, additives, and water, and then dry and roast to obtain a roasted product;

[0023] (2) The roasted product is subjected to ammonium exchange.

[0024] The preparation method of the solid acid catalyst of the present invention can be summarized as first mixing the molecular sieve with a binder containing alumina and other heat-resistant inorganic oxides, and then performing a high-temperature roasting, and there is no roasting before the mixing and molding, only after mixing Roasting is carried out after forming, that is, the primary roasting process after forming. The present invention does not include the process of roasting the molecular sieve first. In the prior art, the mo...

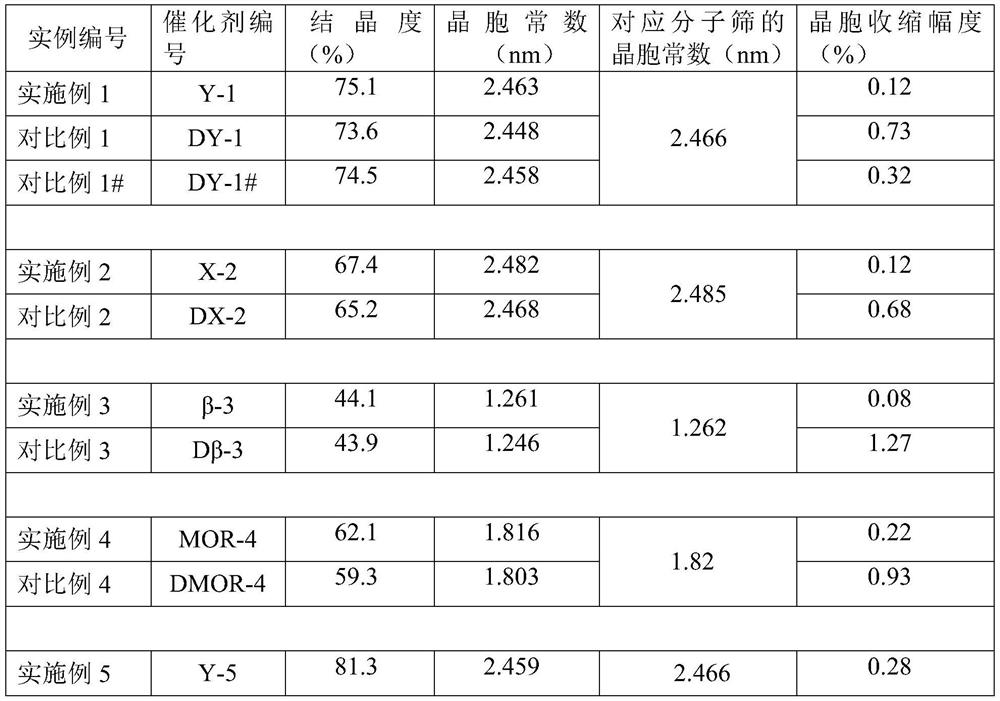

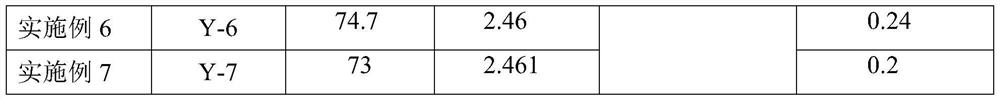

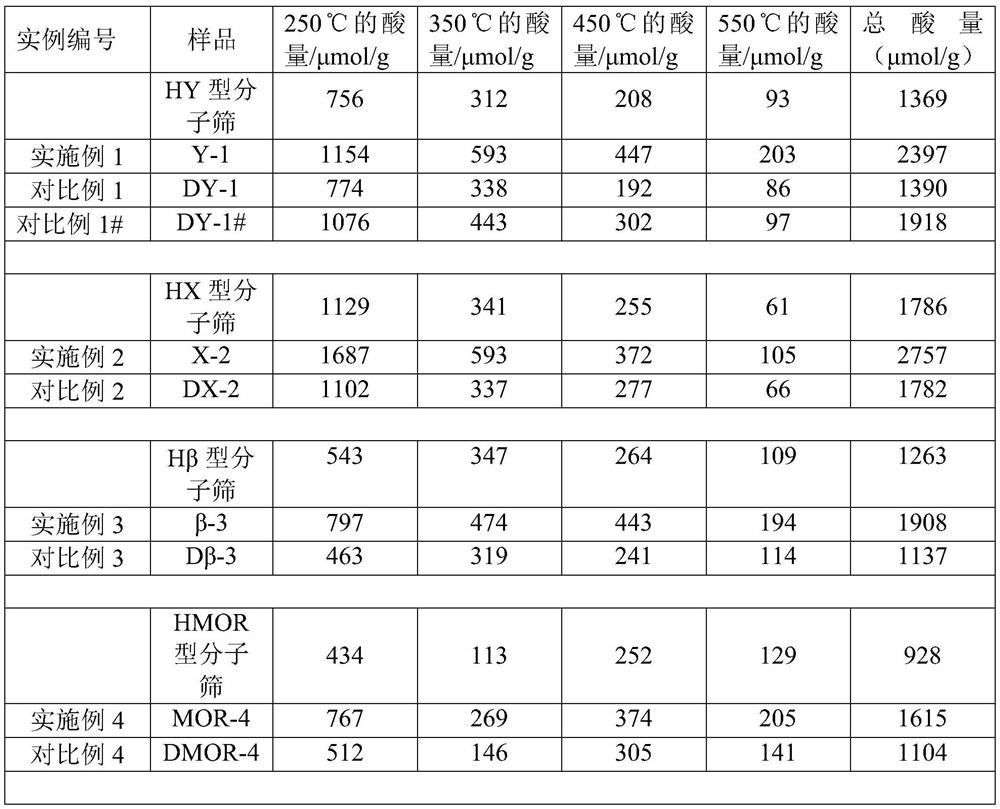

Embodiment 1

[0075] (1) At 85°C, ammonium nitrate solution (NH 4 + The concentration is 2.5mol / L) carry out ammonium exchange 2h to Y-type molecular sieve, then suction filtration, drying;

[0076] (2) The Y-type molecular sieve after the ammonium exchange and the binding agent (based on the dry basis weight of the binding agent, including 50wt% pseudoboehmite and 50wt% SiO 2 Gel) is mixed according to the dry weight percentage of 90:10, and the nitric acid of 3wt% kale powder and 3wt% are added respectively (all based on the total dry weight of the Y-type molecular sieve and the binding agent after ammonium exchange), Add deionized water according to the weight ratio of the total dry weight of other mixtures to water at 1:1, mix uniformly, extrude, and dry at 110°C so that the dry weight of the mixed molding after drying is 65wt% , and then steam roasting at 550°C for 1h, and air roasting at 550°C for 2h to obtain a roasted product;

[0077] (3) Mix the obtained roasted product with am...

Embodiment 2

[0086] (1) At 180°C, ammonium nitrate solution (NH 4 + The concentration is 0.05mol / L) carry out ammonium exchange 4h to X-type molecular sieve, then suction filtration, drying;

[0087] (2) The X-type molecular sieve after the ammonium exchange and the binder (based on the dry basis weight of the binder, including 99wt% pseudo-boehmite and 1wt% TiO 2 Sol) is mixed according to dry basis weight percentage as 80:20, add the nitric acid of 5wt% scallop powder and 1wt% respectively (all with the X-type molecular sieve after the ammonium exchange and the dry basis total weight of binder), according to The weight ratio of the total weight of other mixtures on a dry basis to water is 1:1.2. Add deionized water, mix well and spray molding, and dry at 130°C so that the dry basis weight of the mixed molding after drying is 80wt%, and then Steam roasting at 650°C for 2 hours, and air roasting at 550°C for 2 hours to obtain a roasted product;

[0088] (3) Mix the obtained roasted prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com