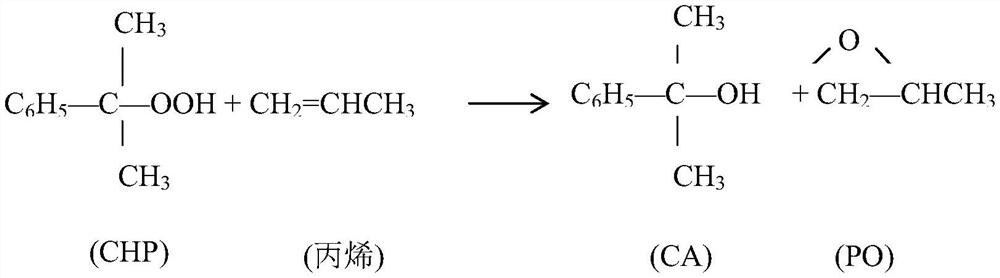

Preparation method of epoxidation catalyst

A catalyst and epoxidation technology, which is applied in the chemical industry, can solve the problems of heavy environmental burden and three wastes, and achieve the effects of avoiding large-scale use, saving water resources and energy consumption, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a reaction kettle with a capacity of 3L (PCF3-3.0 / 316L, Yantai Songling Chemical Equipment Co., Ltd., the same below), add 100g of fumed silica, 2g of tetramethyl titanate and 45g of ammonium carbonate whose mass percentage concentration is 15% The solution was filled with nitrogen to adjust the pressure to 0.3MPa, the stirring was turned on, the temperature was raised to 40 °C for reaction for 24 h, and the titanium-silicon slurry was obtained; the titanium-silicon slurry was cooled to 25 °C and then transferred to a Yaxi liquid nitrogen biological container (10L type, Sichuan Asia West Machinery Co., Ltd., the same below), poured in liquid nitrogen for crystallization for 12 hours, stopped pouring in liquid nitrogen, and dried at 50 °C for 8 hours to obtain the titanium-silicon catalyst precursor; put the titanium-silicon catalyst precursor in an electric heating furnace (YKRL type, Baoying County Electric Heating Appliance Factory, the same below) was aged at 350°C...

Embodiment 2

[0024] Add 100g column chromatography silica gel powder, 12g tetrabutyl titanate and 85g tetramethylammonium hydroxide solution with a concentration of 2% in a reaction kettle with a capacity of 3L, fill with nitrogen to adjust the pressure to 2MPa, start stirring, and heat up. Reaction at 210 °C for 8 hours to obtain titanium-silicon slurry; cool the titanium-silicon slurry to 35 °C and then move it into a Yaxi liquid nitrogen biological container, pour in liquid nitrogen for crystallization for 36 hours, stop pouring liquid nitrogen, and dry at 20 °C for 20 hours to obtain Titanium-silicon catalyst precursor; put the titanium-silicon catalyst precursor in an electric heating furnace at 200°C for 48h aging to obtain an epoxidation catalyst CAT2 # .

Embodiment 3

[0026] Add 100g of thin-layer chromatography silica gel powder, 7g of titanium tetrachloride and 65g of ammonium acetate solution with a concentration of 8.5% by mass into a reaction kettle with a capacity of 3L, fill with nitrogen to adjust the pressure to 1.2MPa, start stirring, and heat up to 105 React at ℃ for 16 hours to obtain titanium-silicon slurry; cool the titanium-silicon slurry to 35 ℃ and move it into a liquid nitrogen biological container in Yaxi, pour in liquid nitrogen for crystallization for 24 hours, stop the introduction of liquid nitrogen, and dry at 40 ℃ for 14 hours to obtain titanium-silicon Catalyst precursor; put the titanium-silicon catalyst precursor in an electric heating furnace at 280°C for 30h aging to obtain an epoxidation catalyst CAT3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com