Permeable reactive barrier and method for repairing polluted underground water by using permeable reactive barrier

A osmotic reaction wall and reaction technology, which is applied in the treatment of contaminated groundwater/leachate, restoration of contaminated soil, water pollutants, etc., can solve the problems of further improvement of the repair effect and limited performance of organic chemical catalytic degradation, etc. Achieve good adsorption and chemical catalytic oxidation degradation performance, improve catalytic oxidation effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, the method for preparing a catalytic oxidation composite carrier with a three-dimensional pore structure includes the following steps: (1) roasting the inorganic oxide composite soil at 600-1000°C; (2) beating the chopped fiber strands , to obtain a slurry after treatment; (3) Mix the inorganic oxide composite soil after the roasting treatment in step (1), the slurry obtained in step (2) and activated carbon evenly, and add bonding components and water to it and further undergo Forming and solidification treatment; (4) Feed the material obtained in step (3) into a sodium hydroxide solution for treatment. After the treatment is completed, solid-liquid separation is carried out, and the separated solid particles are dried and roasted to obtain a composite carrier.

[0033] In the preparation method of the above-mentioned composite carrier with a three-dimensional pore structure, the inorganic oxide composite soil described in step (1) is powdery p...

Embodiment 1

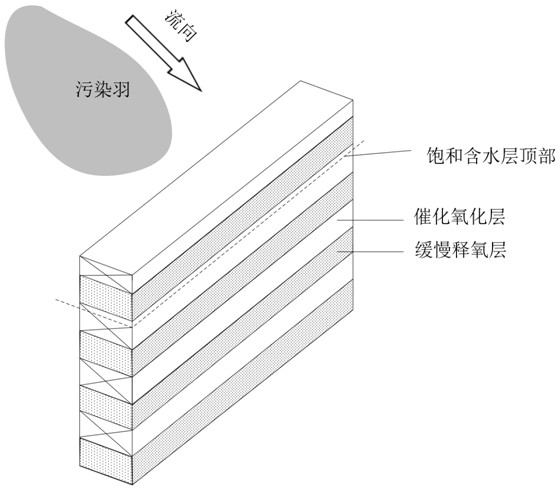

[0045] A certain polluted groundwater is repaired by the PRB provided by the present invention, and the PRB wall is laid out in the vertical direction of water flow, and a 20cm thick slow oxygen release layer is first laid at the bottom, and then a 20cm thick catalytic oxidation layer is laid in alternately. , until the height of the permeable reactive wall reaches 50 cm above the top of the saturated aquifer.

[0046] CaO in slow oxygen releasing layer 2 The mass ratio of powder, attapulgite powder and coarse sand is 2:2:1, and it is used as the filling material for the slow oxygen release layer after mixing.

[0047] The preparation method of the catalytic oxidation composite carrier is as follows: After mixing the activated carbon and the inorganic oxide composite soil treated at 800°C evenly, adding the alkali-soluble polyester cellulose fiber chopped shred slurry with a mass content of 20% and mixing evenly, and then adding a mass content of 25% % sodium silicate binder ...

Embodiment 2

[0052] A certain polluted groundwater is repaired by the PRB provided by the present invention. The PRB wall is laid out in the vertical direction of water flow, and a 15cm-thick slow oxygen-releasing layer is first laid on the bottom, and then a 25cm-thick catalytic oxidation layer is laid alternately. , until the height of the permeable reactive wall reaches 50 cm above the top of the saturated aquifer.

[0053] CaO in slow oxygen releasing layer 2 The mass ratio of powder, attapulgite powder and coarse sand is 2:2:1, and it is used as the filling material for the slow oxygen release layer after mixing.

[0054] The preparation method of the catalytic oxidation composite carrier is as follows: After mixing the activated carbon and the inorganic oxide composite soil treated at 900°C evenly, adding the alkali-soluble hydroxyethyl cellulose fiber chopped shred slurry with a mass content of 15% and mixing evenly, and then adding the mass content 30% sodium silicate binder was k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com