Test system for aircraft climate environment test and configuration method thereof

A climate environment and test system technology, which is applied in the direction of aircraft component testing, climate sustainability, building types, etc., can solve problems such as errors and resource waste experiments, and achieve easy operation, reduce construction costs, and save equipment construction area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

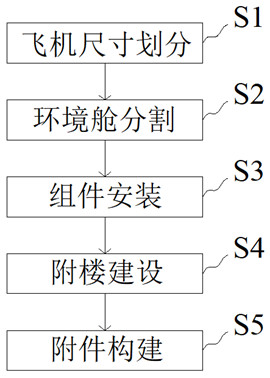

Method used

Image

Examples

Embodiment 1

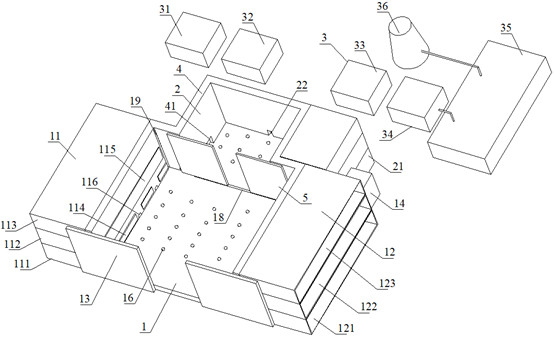

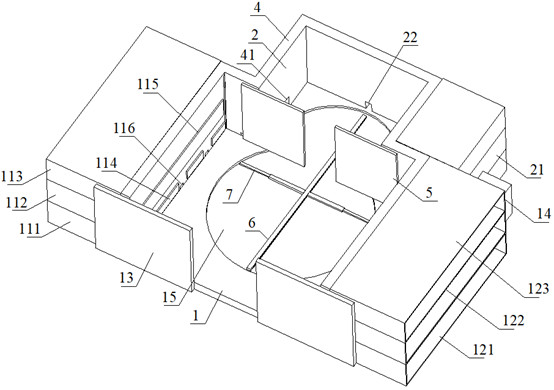

[0045] Such as figure 2 Shown, a kind of test system of aircraft climate environment test, comprises: the big environment cabin 1 and the small environment cabin 2 that are arranged side by side front and back, the first annex building 11 that is positioned at the big environment cabin 1 side and is positioned at the big environment cabin 1 another The second annex building 12 on the side, the third annex building 21 on one side of the small environment cabin 2, the power assembly 3 located at the rear of the small environment cabin 2, the power assembly 3 includes a warehouse 31, a boiler room 32, and a compressed air station arranged side by side. 33 and the circulating water pump room 34, the exhaust space of the exhaust pipe 22 is reserved between the boiler room 32 and the compressed air station 33, a circulating water pool 35 is arranged underground on one side of the circulating water pump room 34, and a There is a circulating cooling tower 36 connected to the circulat...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 lies in that the thickness of the interlayer 4 is different, and the thickness of the interlayer 4 is 1 m.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 lies in that the thickness of the interlayer 4 is different, and the thickness of the interlayer 4 is 2 m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com