Preparation method of porous SiOC ceramic and application thereof in negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, ceramic products, applications, etc., can solve problems such as strong corrosion, and achieve the effects of improved performance, good cycle discharge performance, good rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

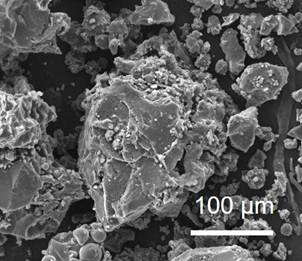

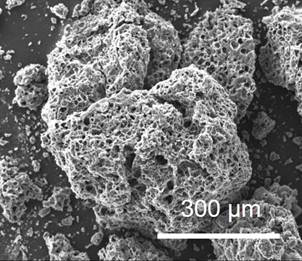

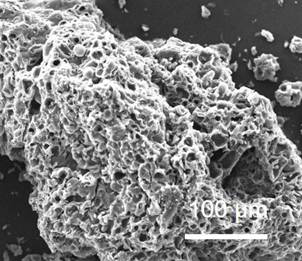

Embodiment 1

[0036] Add 2 ml PhTES into 5 ml EtOH and stir, add 0.9 ml deionized water dropwise, then seal and stir for 9-12 h to obtain PhTES sol;

[0037] Weigh 1.5 g, 2.0 g, 2.5 g, 3.0 g of starch and add to 10 mL of H 2 O / EtOH mixed solution (v / v=1:1), then add 0.15 g, 0.20 g, 0.25 g, 0.30 g KH540 respectively, stir for 30 min, then add PhTES sol solution, at 80 o C stirred until dry to obtain a white powder, placed in 100 o After drying in a C oven for 24 h, at 900 o C heat treatment for 2 h. The synthesized samples were numbered, 1-1, 1-2, 1-3, and 1-4 corresponded to SiOC materials synthesized from 1.5 g, 2.0 g, 2.5 g, and 3.0 g starch, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com